Method for building hollow vascularized heart based on 3D biological printing technology and hollow vascularized heart

A bioprinting, hollow-shaped technology, applied in biochemical equipment and methods, microorganisms, 3D culture, etc., can solve the problems of large-scale printing difficulties, simple hydrogels are easy to collapse, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

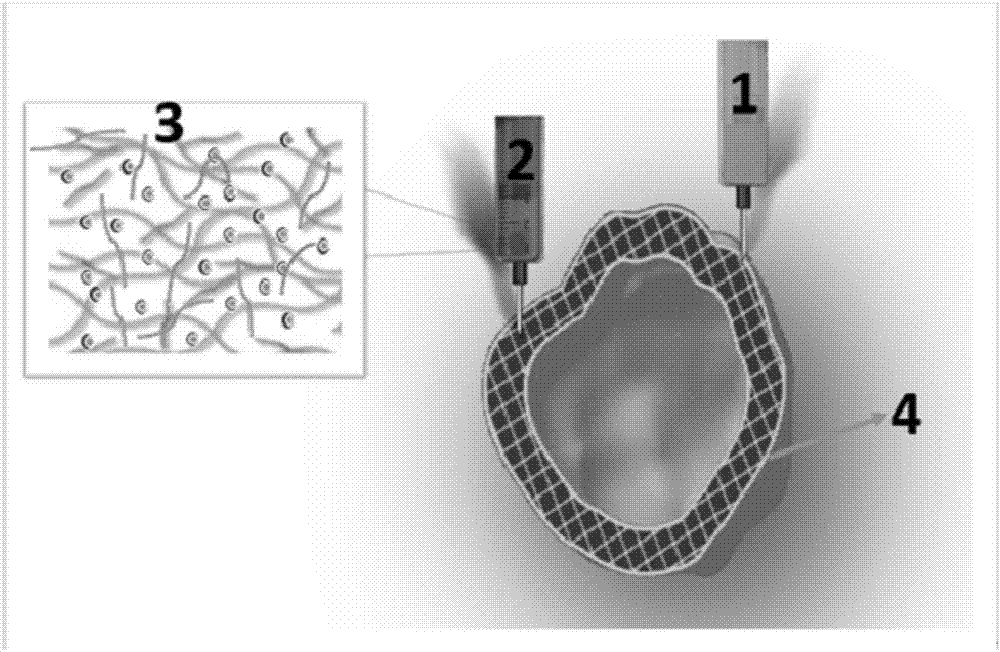

[0032] The preparation method of the bio-ink is as follows: After mixing the third-generation human umbilical vein endothelial cells and SD rat primary cardiomyocytes with platelet-rich plasma, and then mixing with hydrogel, it is obtained. Due to the relatively fluidity of platelet-rich plasma It is better in hydrogel, so by mixing with platelet-rich plasma first, and then mixing with hydrogel, the third-generation human umbilical vein endothelial cells and SD rat primary cardiomyocytes can be evenly dispersed in the bio-ink , no cell aggregation phenomenon occurs, and the quality of bio-ink is improved.

[0033] Preferably, the content of the alginate provided in the preferred embodiment of the present invention in the bio-ink is 2-3wt%, preferably, the content of agarose in the bio-ink is 0.8-1.3wt%, preferably, the third Generation of human umbilical vein endothelial cells at a density of 1 × 10 in bioink 6 cells / ml, preferably, the density of SD rat primary cardiomyocyte...

Embodiment 1

[0055] A hollow vascularized heart prepared by a method for constructing a hollow vascularized heart based on 3D bioprinting technology, which is prepared by the following method:

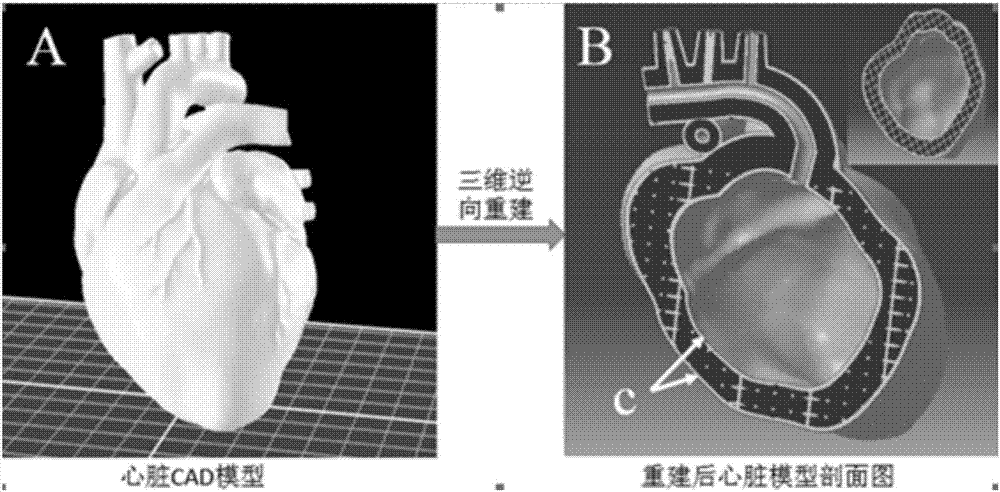

[0056] (1) Cardiac modeling: Import the DICOM format of thin-slice CT scan data of volunteers into Mimics 10.0 software for 3D reconstruction, and then redesign it through reverse modeling technology to design it as a 3D mesh that can be printed with dual nozzles Model, generate STL format data, and then import it into the bioprinting control software, set relevant parameters and slice to form G code.

[0057] (2) Preparation of hydrogel: Weigh 2.5g of biological grade alginate and dissolve it in 50ml of PBS solution, stir magnetically at room temperature until completely dissolved, and autoclave it overnight in a 37°C incubator; take 1g of biological grade low melting point agarose The powder was dissolved in 50ml of PBS solution, heated until completely dissolved, and then autoclaved in a 37°C in...

Embodiment 2

[0064] A hollow vascularized heart prepared by a method for constructing a hollow vascularized heart based on 3D bioprinting technology, which is prepared by the following method:

[0065] (1) Cardiac modeling: Import thin-slice CT scan data of the volunteer heart into Mimics 10.0 software in DICOM format for 3D reconstruction, and then redesign it through reverse modeling technology to design it as a 3D mesh that can be printed with dual nozzles Model, generate STL format data, and then import it into the bioprinting control software, set relevant parameters and slice to form G code.

[0066] (2) Preparation of hydrogel: Weigh 2g of biological grade alginate and dissolve it in 50ml of PBS solution, stir magnetically at room temperature until completely dissolved, and autoclave it overnight in a 37°C incubator; take 2g of biological grade low melting point agarose powder Dissolve in 50ml PBS solution, heat until completely dissolved, autoclave and incubator at 37°C overnight. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com