Ceramic white ink and preparation method thereof

An ink and white technology, applied in the field of ceramic white ink and its preparation, can solve the problems of insufficient antifouling ability, uneven chromaticity of glaze, etc., and achieve good chemical and physical stability, high sintering density and color stability. , The effect of strong anti-fouling ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0077] A ceramic white ink, calculated in parts by weight, comprising:

[0078] 30 parts of zirconium dioxide,

[0079] 5 parts of low-temperature high-boron frit,

[0080] Hydrogenated ricinoleic acid polymer dispersant 5 parts,

[0081] Fatty acid isopropyl ester 10 parts,

[0082] Fatty acid methyl ester 5 parts,

[0083] 44 parts white oil,

[0084] Indigo 0.5 parts,

[0085] 0.5 part of defoamer.

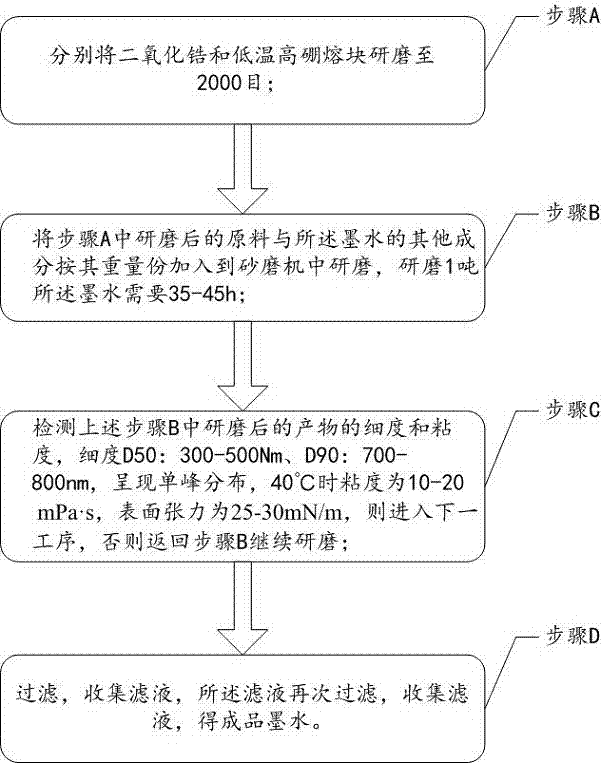

[0086] A preparation method of ceramic white ink, wherein the preparation method comprises the following steps:

[0087] A. Grind zirconium dioxide and low-temperature high-boron frit to 2000 mesh respectively. Grinding the raw materials first will help reduce the grinding time of the subsequent process, so that the materials can be more evenly dispersed and wetted;

[0088] B. Add the raw material after grinding in step A and other components of the ink to grind in a sand mill according to their parts by weight, and it takes 35 hours to grind 1 ton of the ink;

[0089]...

Embodiment 2

[0093] A ceramic white ink, calculated in parts by weight, comprising:

[0094] 35 parts of zirconium dioxide,

[0095] 8 parts of low-temperature high-boron frit,

[0096] Hydrogenated ricinoleic acid polymer dispersant 8 parts,

[0097] 3 parts of diisobutyl succinate,

[0098] 5 parts of diisobutyl glutarate,

[0099] 5 parts of diisobutyl adipate,

[0100] 33 parts white oil,

[0101] Indigo 0.6 parts,

[0102] 0.6 part of defoamer.

[0103] A preparation method of ceramic white ink, wherein the preparation method comprises the following steps:

[0104] A. Grind zirconium dioxide and low-temperature high-boron frit to 2000 mesh respectively. Grinding the raw materials first will help reduce the grinding time of the subsequent process, so that the materials can be more evenly dispersed and wetted;

[0105] B. Add the raw material after grinding in step A and other components of the ink to grind in a sand mill according to their parts by weight, and it takes 40 hours...

Embodiment 3

[0110] A ceramic white ink, calculated in parts by weight, comprising:

[0111] 40 parts of zirconium dioxide,

[0112] 10 parts of low-temperature high-boron frit,

[0113] Hydrogenated ricinoleic acid polymer dispersant 8 parts,

[0114] 16 parts of fatty acid ethylhexyl ester,

[0115] 25 parts of solvent,

[0116] Indigo 0.7 parts

[0117] 0.7 part of defoamer.

[0118] A preparation method of ceramic ink, wherein the preparation method comprises the following steps:

[0119] A. Grind zirconium dioxide and low-temperature high-boron frit to 2000 mesh respectively. Grinding the raw materials first will help reduce the grinding time of the subsequent process, so that the materials can be more evenly dispersed and wetted;

[0120] B. Add the raw material after grinding in step A and other components of the ink to grind in a sand mill according to their parts by weight, and it takes 45 hours to grind 1 ton of the ink;

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface tension | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com