Scratch-resistant stain-repellent solar heat insulation membrane

A solar thermal insulation film and antifouling technology, applied in synthetic resin layered products, layered products, chemical instruments and methods, etc., can solve the problems of poor scratch resistance, difficult discharge, and low light transmittance of solar thermal insulation film. , to achieve the effect of strong anti-fouling and easy installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] The first optical grade film layer 16 um~36 um

[0035] Polyurethane adhesive layer 2 um~20 um

[0036] Ultraviolet and infrared strengthening layer 2 um~30um

[0037] Metal or metal oxide layer 2 um~30 um

[0038] The second optical grade film layer 16 um~36 um

[0039] Install adhesive layer 10 um~40 um

[0040] Release film 9 um ~ 50 um.

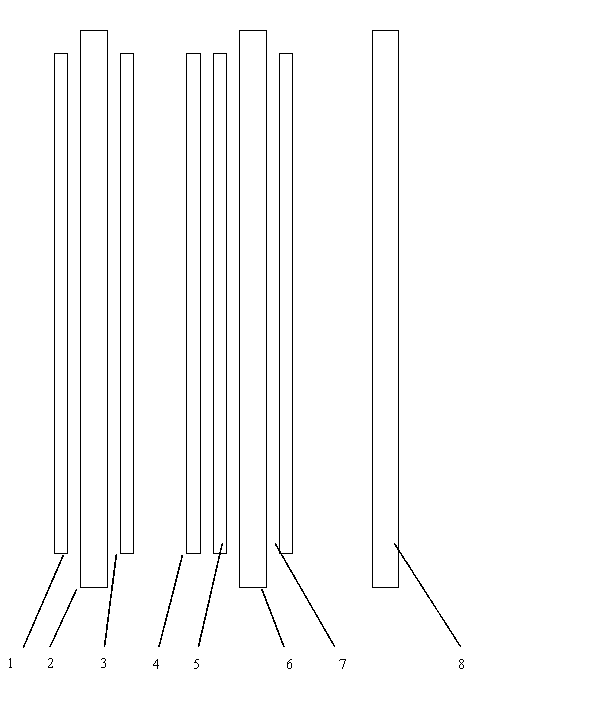

[0041] like figure 1 A kind of anti-scratch and anti-fouling solar thermal insulation film shown, it comprises: the anti-scratch anti-fouling layer that thickness is 3um, the first optical grade film layer base material 2 that is 23um in thickness, the polyurethane adhesive layer 3 that is 8um in thickness, A UV-IR shielding reinforcing layer 4 with a thickness of 4um, a metal layer 5 with a thickness of 2um, a second optical film layer substrate 6 with a thickness of 23um, an installation adhesive layer 7 with a thickness of 8um, and a release film 8 with a thickness of 23um ; In this embodiment, the anti-scratch and anti-f...

Embodiment 2

[0050] The specific steps of the manufacturing method of the above-mentioned anti-scratch and anti-fouling solar heat insulation film are as follows:

[0051] (1) On the corona surface of the 23 um second optical grade film layer, a 4 um metal layer is produced by chemical vapor deposition; the requirement for the PET film substrate is high transparency, and the visible light transmittance is >92% , haze <1%. The metal layer produced by the chemical evaporation method has the characteristics of heat insulation and ultraviolet radiation.

[0052] (2) On the metal layer, a 2 um UV-IR blocking layer is fabricated by magnetron sputtering;

[0053] (3) On the corona surface of the first optical grade film layer of 16 um, coat an 8 um polyurethane adhesive layer and compound it with an ultraviolet and infrared blocking strengthening layer;

[0054] (4) Then apply an 8um mounting adhesive layer on the non-corona surface of the second optical grade film layer, and compound it with a...

Embodiment 3

[0058] The specific steps of the manufacturing method of the above-mentioned anti-scratch and anti-fouling solar heat insulation film are as follows:

[0059] (1) On the corona surface of the 23 um second optical grade film layer, a 3um metal layer is produced by chemical evaporation; among them, the requirement for the PET film substrate is high transparency, and the visible light transmittance is >92%. Haze <1%. The metal layer produced by the chemical evaporation method has the characteristics of heat insulation and ultraviolet radiation.

[0060] (2) On the metal layer, a 3 um UV-IR blocking layer is fabricated by magnetron sputtering;

[0061] (3) Coating a 4 um polyurethane adhesive layer on the corona surface of the 23 um first optical grade film layer and compounding with the ultraviolet and infrared blocking strengthening layer;

[0062] (4) Then apply an 8um mounting adhesive layer on the non-corona surface of the second optical grade film layer, and compound it wi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com