Manufacturing method of goggle lens

The technology of a kind of goggle lens and manufacturing method is applied in the field of optics, which can solve problems such as vision damage, and achieve the effect of reducing damage and strong antifouling performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Embodiment 1: the preparation of raw material mixture

[0021] One day before the curing reaction, in parts by weight, 1000±0.1 parts of B-magic OG, 10±0.1 parts of M-22, 3±0.01 parts of UV-1, 20±0.01 parts of T-13 and 1.8±0.1 parts 0.01 part of V-65 (all from UNOCHEM CO., CTD, each code is the product code of the company) was mixed at room temperature to make a raw material mixture.

[0022] After the raw materials are mixed, they are heated under stirring in a stirring pot, and the viscosity is tested after the temperature reaches 40°C. After the viscosity reaches 60 mpa.s, use a cold water bath to quickly cool down to 25°C while stirring, and store for later use.

Embodiment 2

[0023] Embodiment 2: the preparation of lens mold

[0024] Assemble the selected lens upper mold, lower mold and spacer with a suitable curvature, put the rubber ring on the outside, and pay attention to align the injection hole of the rubber ring with the gap of the spacer to facilitate filling.

Embodiment 3

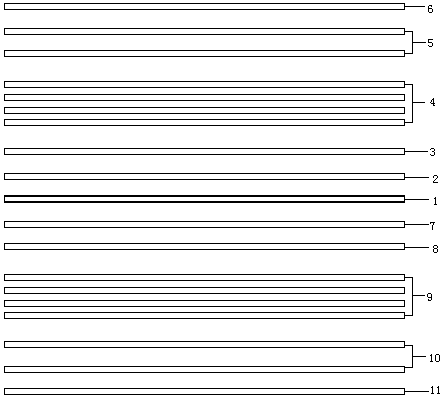

[0025] Example 3: Curing

[0026] After pouring the liquid stock mixture into the prepared mold, heat cure using the cycle shown in the table below

[0027] temperature °C 36 48 48 65 90 90 60 running time h time h 3 10 2 3 1 2 1 22

[0028] After the curing is completed, after the mold drops to room temperature, the rubber ring is removed, and the mold is separated to obtain the lens.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com