Composite sleeve penetrating through cabinet

A casing and layer composite technology, applied in electrical components, insulators and other directions, can solve problems such as small creepage distance, switch cabinet equipment failure, pollution flashover discharge, etc., to achieve high withstand voltage insulation performance and improve installation convenience. , The effect of strong oxidation resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] A composite cabinet-through casing of the present invention will be further described below in conjunction with the accompanying drawings;

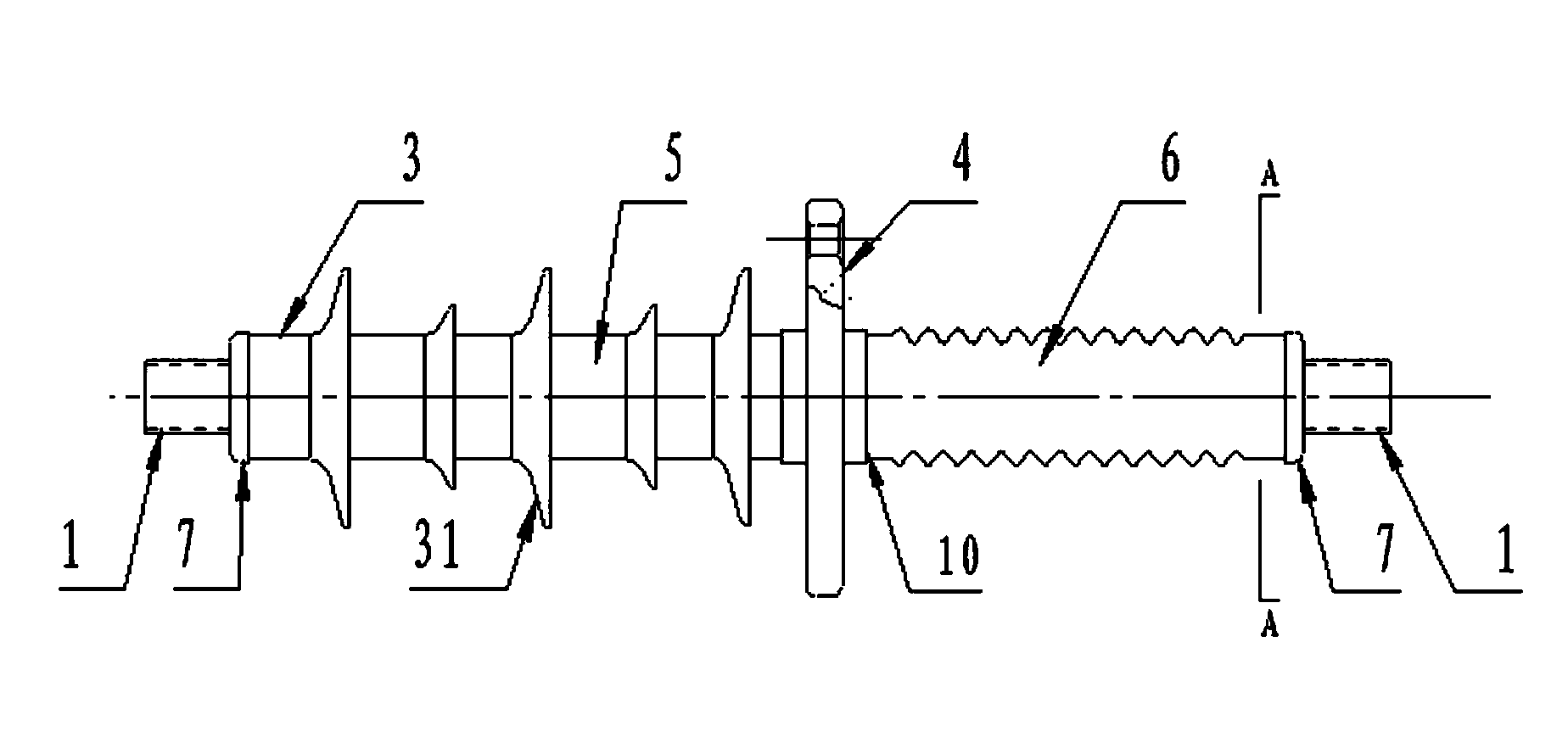

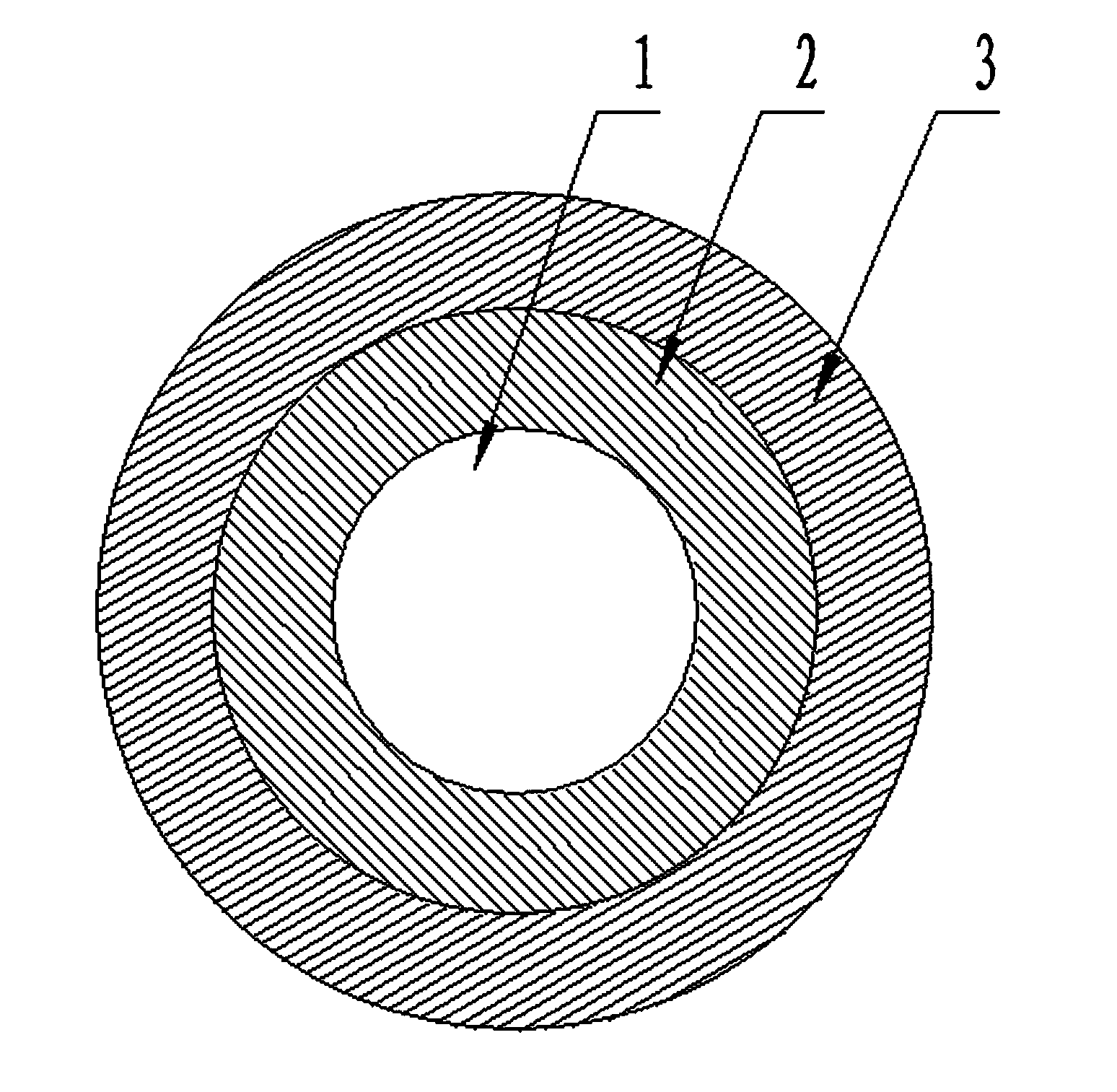

[0018] Depend on figure 1 , figure 2 It can be seen that a composite cabinet penetration bushing of the present invention includes a power bus pipe 10 composed of a conductive copper rod core 1, the conductive copper rod core 1 is coated with at least one layer of composite silicone rubber layer 3, and the power bus pipe 10 The middle part is provided with a flange plate 4, and the flange plate 4 divides the power bus pipe 10 into a first section of power bus pipe 5 and a second section of power bus pipe 6, and the composite silicon rubber layer 3 of the first section of power bus pipe 5 is An umbrella skirt 31 is provided on the surface.

[0019] The technology of this embodiment is mainly solved by the following technical solutions: through the outer coating of the conductive copper rod core 1 with the composite silicon rubber...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com