Follow-up permanent magnetic field arc extinguishing mechanism in double-breakpoint direct-acting contactor

A permanent magnetic field, direct-acting technology, applied in the direction of relays, electromagnetic relays, detailed information of electromagnetic relays, etc., can solve the problems of reduced voltage withstand insulation performance of devices, lack of arc extinguishing magnetic field, variable size, and fast diffusion of charged particles. , to achieve the effect of fast extinguishing speed, avoiding too slow arcing speed, and high withstand voltage insulation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

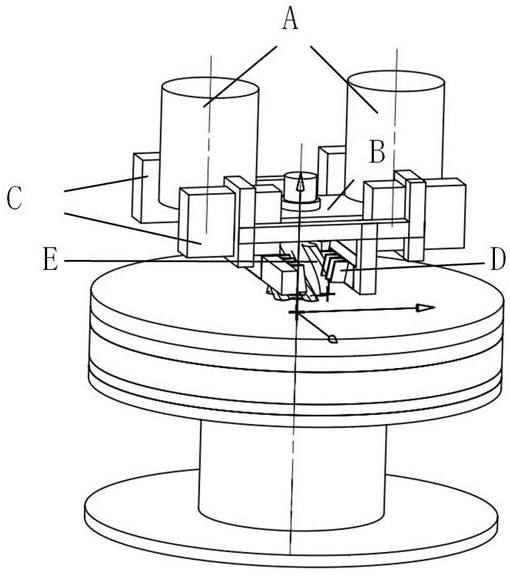

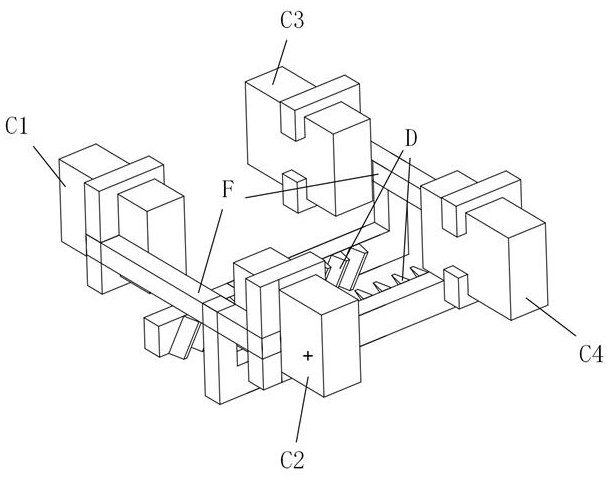

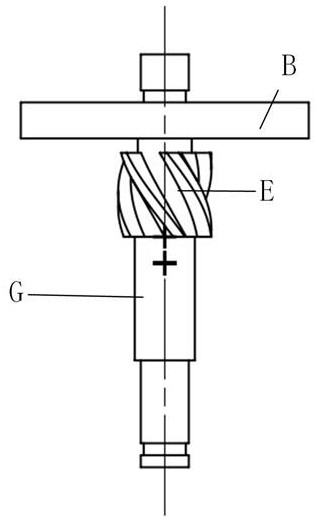

[0016] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings, but it is not limited thereto. Any modification or equivalent replacement of the technical solution of the present invention without departing from the spirit and scope of the technical solution of the present invention should be covered by the present invention. within the scope of protection.

[0017] The present invention provides a design method of a servo permanent magnet magnetic field arc extinguishing mechanism applied in a double breakpoint direct-acting contactor arc extinguishing system. The design idea includes the following points:

[0018] 1. Using the typical magnetic blowout method, the permanent magnets are respectively placed on both sides of the gap between the moving and static contacts. The magnetic field generated by them will cause the arc to be driven by electromotive force, thus elongating to both sides, and the arc will ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com