Dynamic arc extinguishing system

A kind of arc extinguishing and dynamic technology, applied in the direction of circuit breaker contacts, circuit breaker parts, etc., it can solve the problems of continuous arc burning, impact of product breaking capacity, and reduction of product electrical life, etc., to achieve fast arc extinguishing speed and reduce contacts. Ablation time, simple structure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

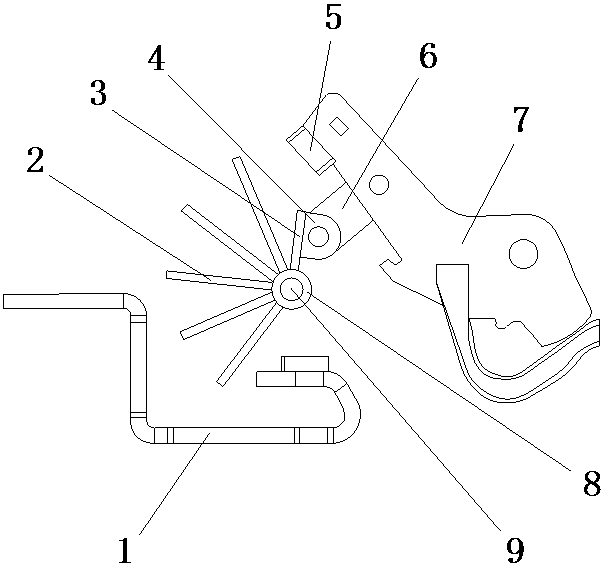

[0019] Such as figure 1 As shown, a dynamic arc extinguishing system corresponds to a circuit breaker 1 . A moving contact assembly 7 is connected to the circuit breaker 1 through a rotating shaft, and a contact plate 5 is arranged on the moving contact assembly 7 . Both the circuit breaker and the moving contact assembly are existing designs, and their structures and principles will not be repeated here.

[0020] The dynamic arc extinguishing system includes a connecting rod 6 connected to a moving contact assembly 7, and the connecting rod 6 is connected with a transmission assembly. The transmission assembly is connected with a dynamic arc extinguishing mechanism. There is a circular groove inside the circuit breaker 1 . The contact plate and the dynamic arc extinguishing mechanism can be closed or disconnected.

[0021] The dynamic arc extinguishing mechanism includes a circular rotating shaft 8 that is connected to the rotating shaft 9 through transmission, and the circ...

specific Embodiment approach

[0023] The specific implementation method is: when the contact is disconnected, the moving contact drives the arc extinguishing chamber to rotate counterclockwise with the launch shaft as the center by the connecting rod, the arc enters the arc extinguishing chamber, the arc is cut by the grid, and as the moving contact opens As the distance increases, the arc extinguishing chamber is also constantly rotating, and the arc is also being dynamically cut by the grid, so the arc energy can be reduced rapidly, and its emission structure is also conducive to the divergence of arc heat.

[0024] The arc extinguishing chamber of the present invention has an emissive overall structure, the arc enters the arc extinguishing chamber at the best angle at all times, the arc extinguishing speed is fast, the breaking performance of the product is improved, the contact ablation time is reduced, and the electrical life is improved.

[0025] The arc extinguishing chamber of the present invention ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com