Contact structure of dual-power switch

A dual power switch and contact technology, which is applied in the direction of electric switches, contact drive mechanisms, contacts, etc., can solve the problems of springback and slow joint speed of moving contacts, and achieve the effect of avoiding springback and improving joint speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

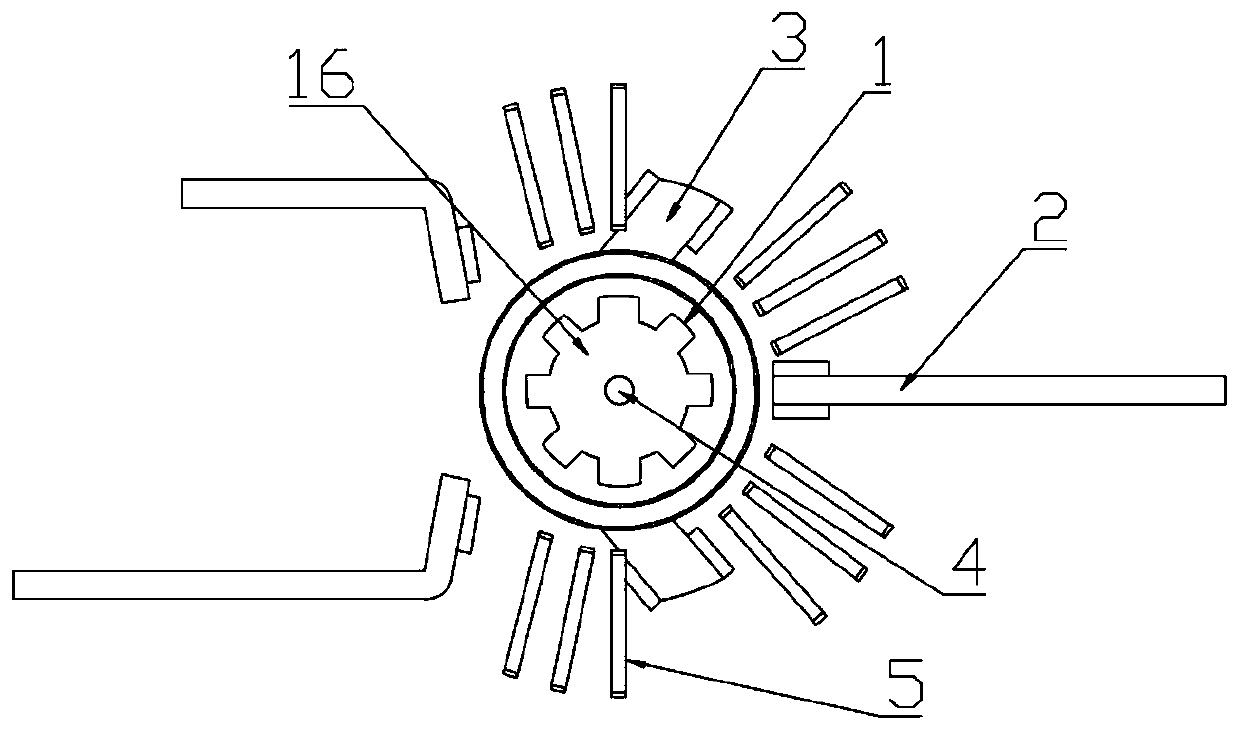

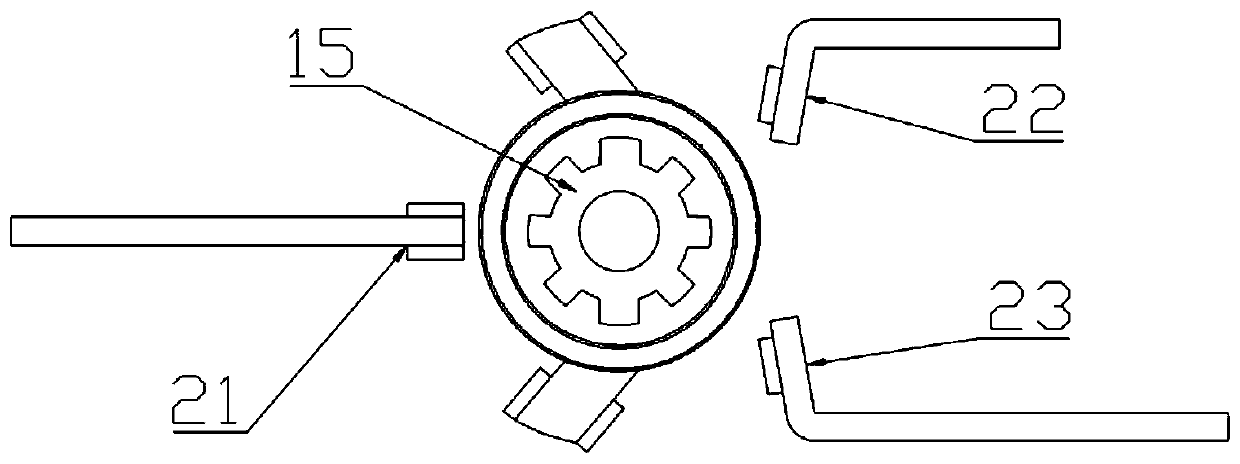

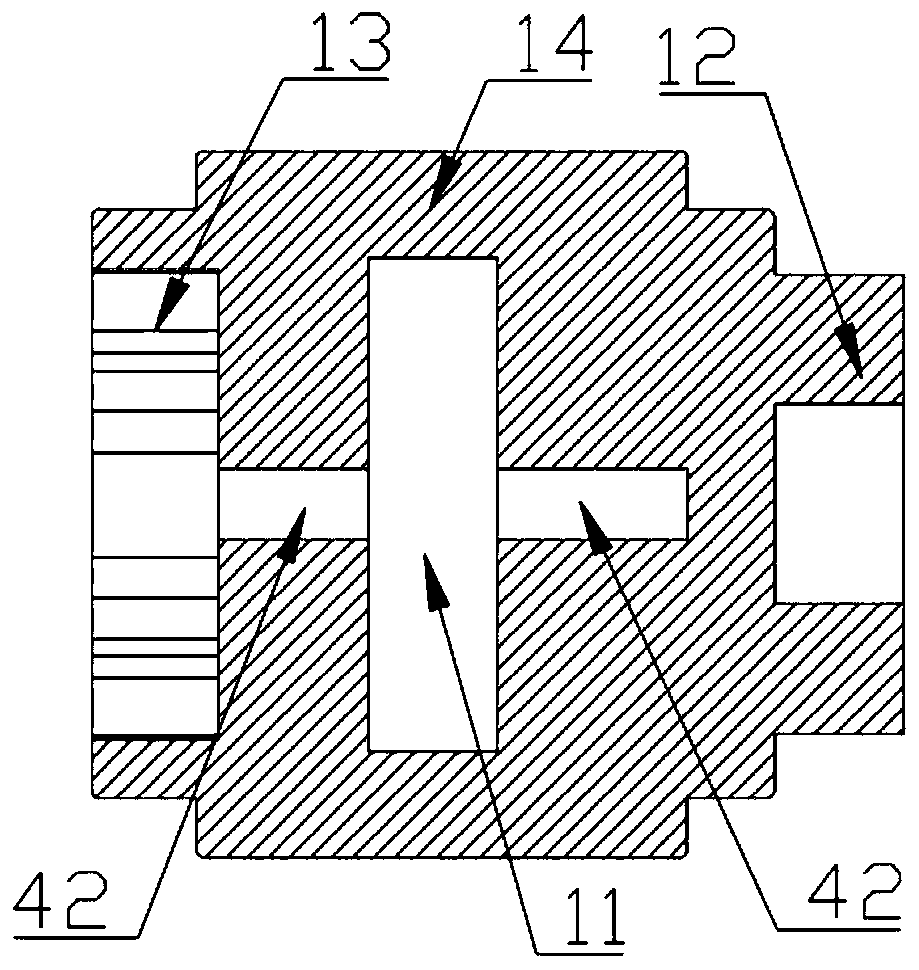

[0043] This example provides Figure 1-5 The shown contact structure of a dual power switch includes:

[0044] The insulating rotating shaft 1 is controlled to rotate by the operating mechanism, and includes an accommodating chamber 11 radially penetrating through the insulating rotating shaft 1;

[0045] The static contact assembly 2 is arranged along the outer circumference of the insulating shaft 1, and includes a first static contact 21, a second static contact 22 and a third static contact 23;

[0046] The moving contact 3 passes through the accommodating cavity 11, the width of the moving contact 3 is smaller than the width of the opening of the accommodating cavity 11, and the moving contact 3 and the insulating shaft 1 are provided with Positioning structure 4, the moving contact 3 can rotate around the positioning structure 4, with the rotation of the insulating shaft 1, the two ends of the moving contact 3 can be respectively connected with the first static contact ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com