Preparation method of compound adsorbent mixture, adsorbent particle and compound adsorbent for purifying VOCs

A composite adsorption and adsorbent technology, which is applied in the direction of chemical instruments and methods, separation methods, and other chemical processes, can solve the problems of demanding industrial equipment, cumbersome method procedures, and high cost of adsorbents, so as to improve the adsorption effect and reduce costs. , is beneficial to the effect of removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

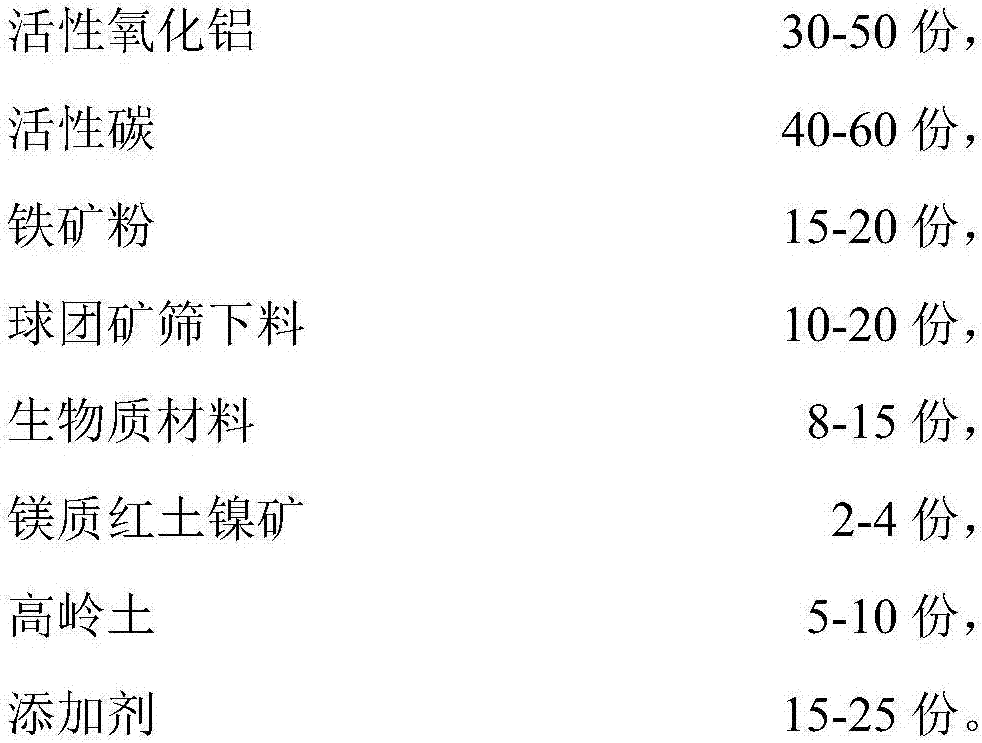

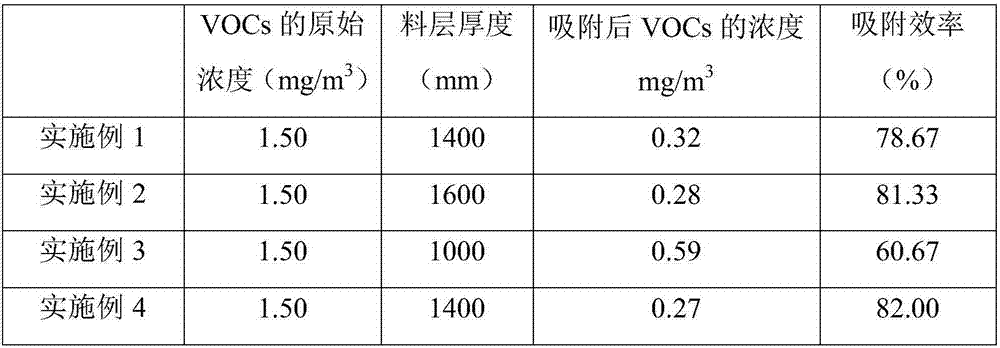

Embodiment 1

[0036] A preparation method of a composite adsorbent mix material, adsorbent particles and a composite adsorbent for purifying VOCs of the present embodiment, each component of the adsorbent is composed of the following parts by mass: 30 kg of activated alumina, 40 kg of activated carbon, 15kg of iron ore powder, 10kg of pellet ore sieve, 8kg of biomass material, 2kg of magnesia laterite nickel ore, 5kg of kaolin, and 15kg of additives. The creative component distribution ratio, as well as the special particle size composition of activated alumina and activated carbon, make the adsorbent have high porosity and specific surface area. When VOCs are in contact with the adsorbent, the adsorbent can fully contact with VOCs, which is beneficial to The removal of VOCs further improves the adsorption capacity of the adsorbent while increasing the specific surface area.

[0037] It is worth noting that: the particle size of the activated alumina is composed of the following mass percen...

Embodiment 2

[0059] A preparation method of a composite adsorbent mix material, adsorbent particles and a composite adsorbent for purifying VOCs of the present embodiment, each component of the adsorbent is composed of the following parts by mass: 35 kg of activated alumina, 55 kg of activated carbon, 18kg of iron ore powder, 15kg of pellet ore sieve, 12kg of biomass material, 3kg of magnesia laterite nickel ore, 8kg of kaolin, and 20kg of additives. The creative component distribution ratio, as well as the special particle size composition of activated alumina and activated carbon, make the adsorbent have high porosity and specific surface area. When VOCs are in contact with the adsorbent, the adsorbent can fully contact with VOCs, which is beneficial to The removal of VOCs further improves the adsorption capacity of the adsorbent while increasing the specific surface area.

[0060] The preparation method of a kind of composite adsorbent particles of the present embodiment

[0061] Step ...

Embodiment 3

[0077]A preparation method of a composite adsorbent mix material, adsorbent particles and a composite adsorbent for purifying VOCs in this embodiment, each component of the adsorbent is composed of the following parts by mass: 50 kg of activated alumina, 60 kg of activated carbon, 20kg of iron ore powder, 20kg of pellets under sieve, 15kg of biomass material, 4kg of magnesia laterite nickel ore, 10kg of kaolin, and 25kg of additives. The creative component distribution ratio, as well as the special particle size composition of activated alumina and activated carbon, make the adsorbent have high porosity and specific surface area. When VOCs are in contact with the adsorbent, the adsorbent can fully contact with VOCs, which is beneficial to The removal of VOCs further improves the adsorption capacity of the adsorbent while increasing the specific surface area.

[0078] The preparation method of a kind of composite adsorbent particles of the present embodiment

[0079] Step 1: M...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com