A method for improving the appearance of surimi products during the cooking process by microwave

A surimi product and curing technology, which is applied in the field of food processing, can solve the problems of limiting the universality of microwave-heated surimi products and the single form of heated surimi products, so as to shorten the production cycle, improve the appearance, avoid disappearance and The effect of deterioration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] The slaking process operation is carried out by using microwave steam combined with surimi product processing equipment, which has been disclosed in the invention patent with application number 201610893370.1.

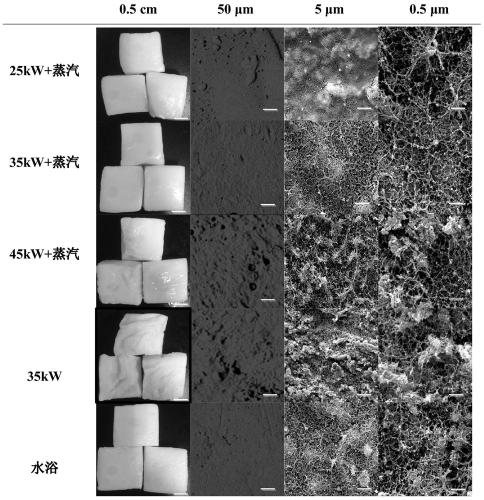

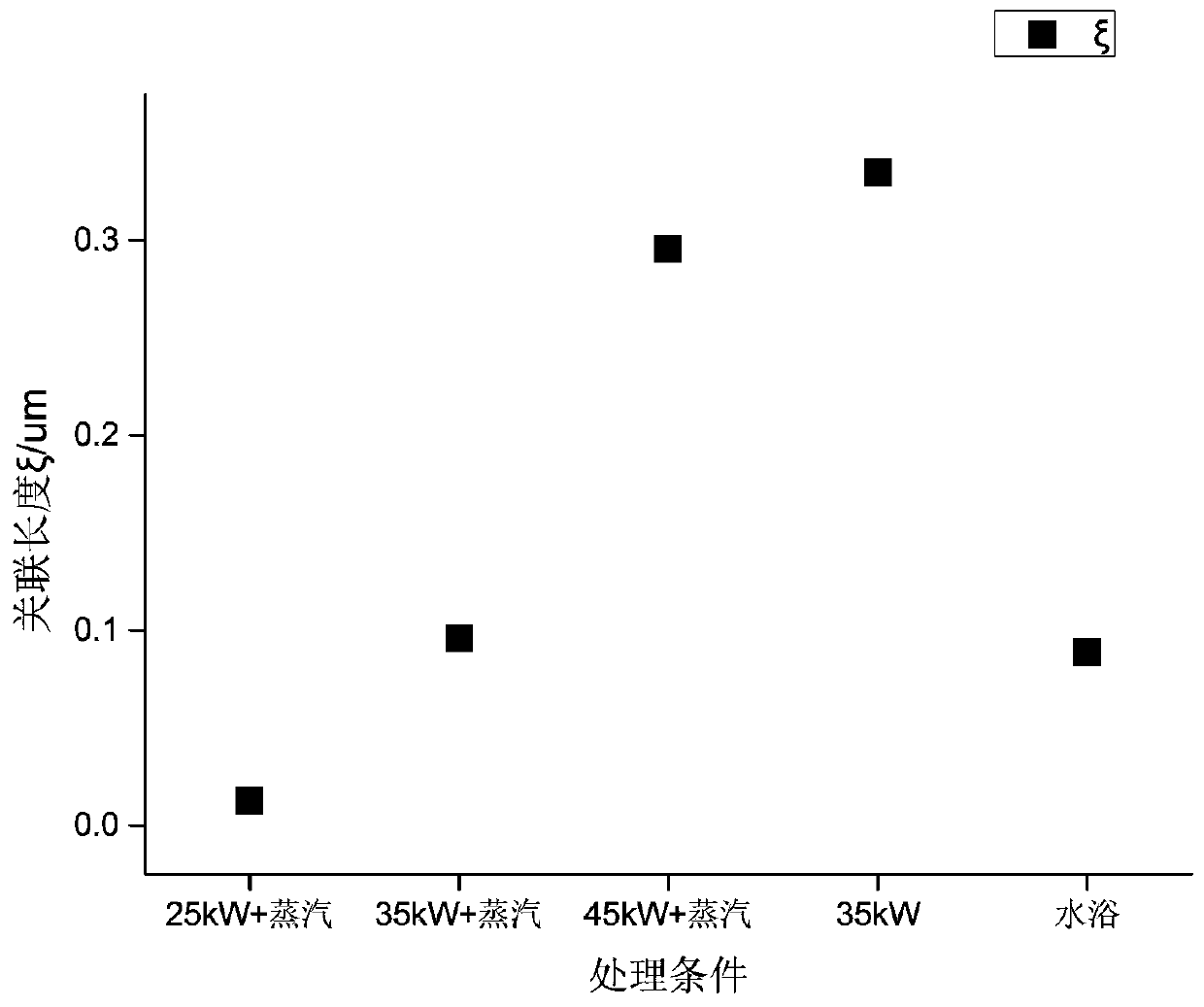

[0043] Mix surimi with auxiliary raw materials such as starch, soybean protein, egg white, salt, etc., adjust the moisture content of surimi products to 78% to 82%, and connect to the end of the slurry line, and the surimi product slurry passes through the grouting head to form a cross section It is in the shape of 2*1.2cm strips, falls on the conveyor belt, and is transported by the motor to the microwave action box. 1 minute before the slurry enters the microwave box, steam is introduced into the box through the steam component, so that the box is filled with steam, and the inside of the box is preheated.

[0044] The cooking method is mainly microwave heating, supplemented by steam heating, and the center temperature of the surimi products after microwave cur...

Embodiment 2

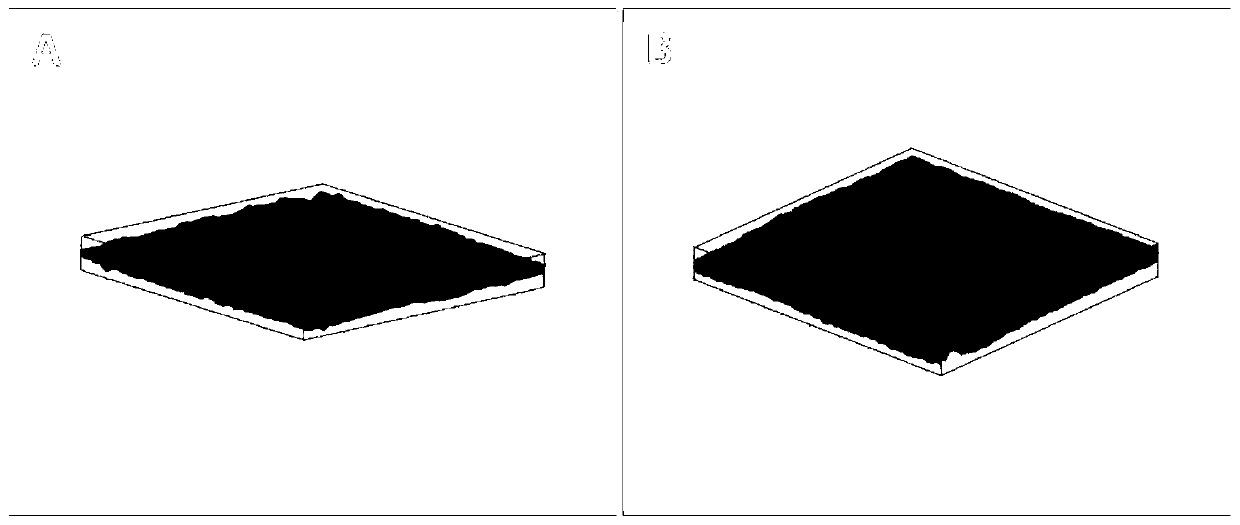

[0062] The slurry produced by the grouting head is a long cylindrical shape with a diameter of 3 cm. The power of controlling microwave curing is 35kW, the pressure of the steam used is 0.6MPa, the temperature is 158°C, and the steam flow rate is 0.43m 3 / h, the heating time is 1min30s, the center temperature of the heated surimi product is 83°C, and its appearance is as follows Figure 4 As shown in B, the apparent morphology has been significantly improved, and the surface is smooth without holes, which meets the production requirements. The photos of the appearance of cylindrical surimi products after being treated with microwave (35kW) for the same time (1min 30s) are as follows: Figure 4 As shown in A, it can be seen that the surface of the surimi product has obvious holes, and there is a phenomenon of rough dry burnt.

Embodiment 3

[0064] Taking block fish tofu as an example, the slurry produced by the grouting head is in a long strip shape, and the final size of fish tofu is 2*2*1.5cm. Simply using 35kW microwave power for aging treatment, the photos of the appearance of cylindrical surimi products are as follows: Figure 5 As shown in A, the surface of the surimi product is rough and dry. The combination of microwave and steam is used for treatment, the power of microwave curing is 30kW, the pressure of steam used is 0.6MPa, the temperature is 158°C, and the steam flow rate is 0.37m 3 / h, the heating time is 1min 10s, the central temperature of the heated surimi product is 85°C, and the appearance of the processed surimi product is as follows Figure 5 As shown in B, the surface is smooth and the appearance is obviously improved, meeting the production requirements.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com