Organic-inorganic composite water-absorbing material based on polyaspartic acid and nano montmorillonite and preparation method thereof

A technology of polyaspartic acid and water-absorbing material, applied in the field of high-performance organic-inorganic composite water-absorbing material and its preparation, can solve the problems of poor ability to absorb electrolyte solution, poor compressive ability of polymer, decreased water-absorbing ability, etc. The effect of improving gel strength, excellent water retention performance and high water absorption rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

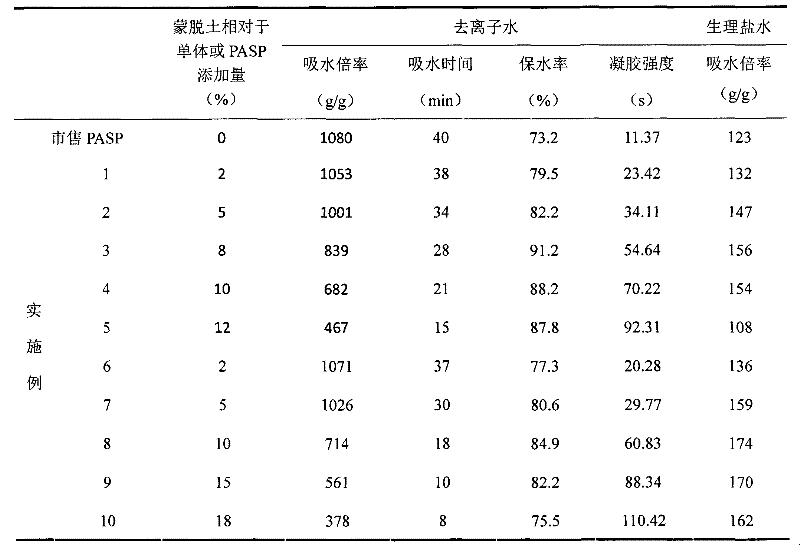

Examples

Embodiment 1

[0039] Disperse 2g of nano-montmorillonite in 20 times the mass of deionized water, stir at high speed for 0.5h to form a stable suspension, add 100g of L-aspartic acid, 25ml of 85% H 3 PO 4 Solution, 0.1g cross-linking agent Bis, ultrasonic dispersion, pass N 2 protection, and then raise the temperature to 200°C to react for 2 hours, then lower the temperature, wash with methanol and water until neutral, and dry to obtain the intermediate product.

[0040] The above intermediate product was crushed and hydrolyzed with NaOH (2mol / L) solution at about 50°C for 1-1.5h. The amount of NaOH was used to keep the pH of the final hydrolyzed solution between 10-12. Then neutralize with HCl, the degree of neutralization is 70-80%. Pour the neutralized hydrolyzate into a saturated solution of sodium chloride-methanol which is stirred vigorously for precipitation, filter, wash with methanol for several times, and store at a temperature of 40°C. Drying under the condition of blowing air ...

Embodiment 2

[0042] Disperse 5g of nano-montmorillonite in 20 times the mass of deionized water, stir at high speed for 0.5h to form a stable suspension, add 100g of L-aspartic acid, 25ml of 85% H 3 PO 4 Solution, 0.1g cross-linking agent Bis, ultrasonic dispersion, pass N 2 protection, and then raise the temperature to 200°C to react for 2 hours, then lower the temperature, wash with methanol and water until neutral, and dry to obtain the intermediate product.

[0043] The above intermediate product was crushed and hydrolyzed with NaOH (2mol / L) solution at about 50°C for 1-1.5h. The amount of NaOH was used to keep the pH of the final hydrolyzed solution between 10-12. Then neutralize with HCl, the degree of neutralization is 70-80%. Pour the neutralized hydrolyzate into a saturated solution of sodium chloride-methanol which is stirred vigorously for precipitation, filter, wash with methanol for several times, and store at a temperature of 40°C. Drying under the condition of blowing air ...

Embodiment 3

[0045] Disperse 8g of nano-montmorillonite in 20 times the mass of deionized water, stir at high speed for 0.5h to form a stable suspension, add 100g of L-aspartic acid, 25ml of 85% H 3 PO 4 Solution, 0.1g cross-linking agent Bis, ultrasonic dispersion, pass N 2 protection, and then raise the temperature to 200°C to react for 2 hours, then lower the temperature, wash with methanol and water until neutral, and dry to obtain the intermediate product.

[0046] The above intermediate product was crushed and hydrolyzed with NaOH (2mol / L) solution at about 50°C for 1-1.5h. The amount of NaOH was used to keep the pH of the final hydrolyzed solution between 10-12. Then neutralize with HCl, the degree of neutralization is 70-80%. Pour the neutralized hydrolyzate into a saturated solution of sodium chloride-methanol which is stirred vigorously for precipitation, filter, wash with methanol for several times, and store at a temperature of 40°C. Drying under the condition of blowing air ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com