Special fertilizer for corn with water holding and soil improvement effects and preparation thereof

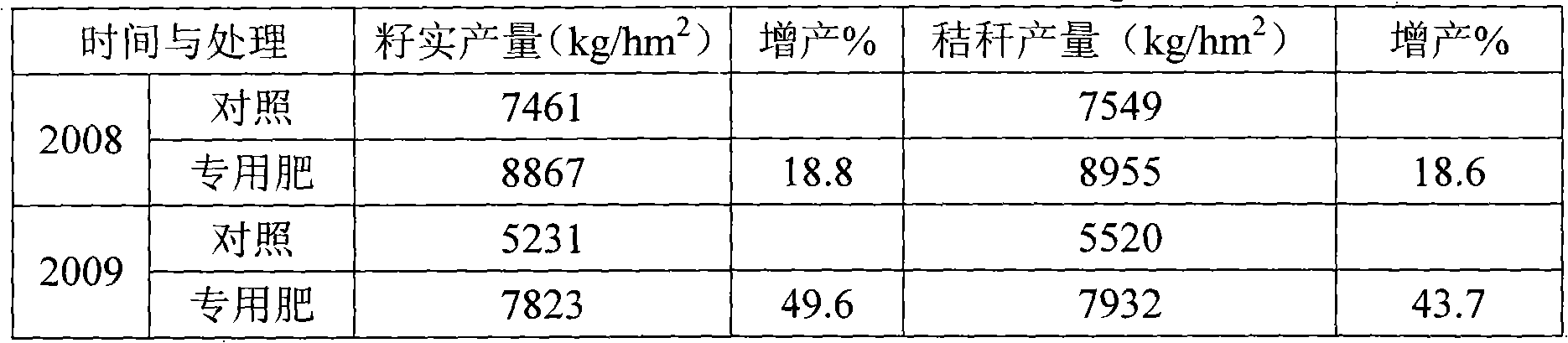

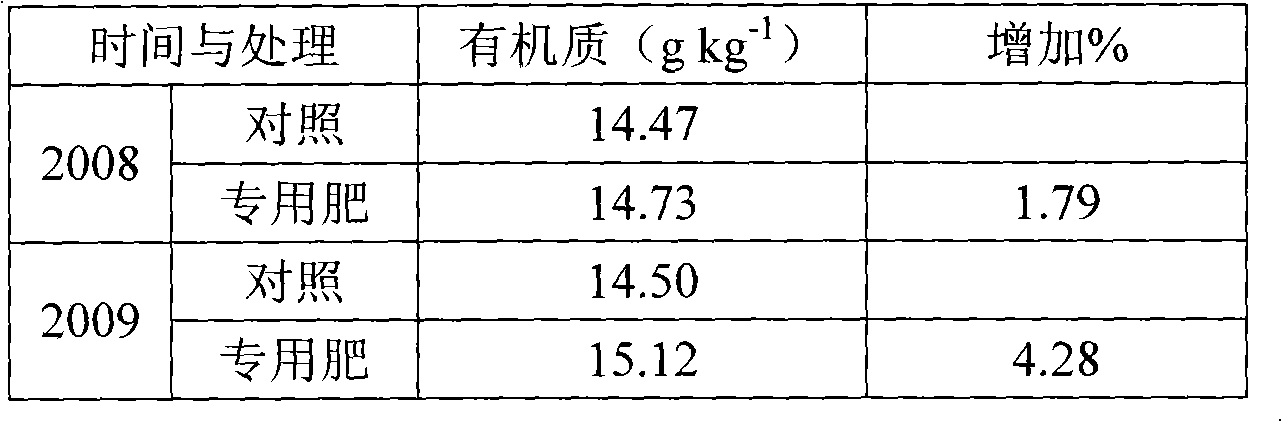

A corn-specific fertilizer and soil improvement technology, applied in the field of special fertilizers, can solve problems such as the decrease in the quantity and quality of aggregates, the decrease in soil organic matter content, the deterioration of soil physical properties, etc. The effect of water and fertilizer retention performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Put 3 kg of wood bran, 30 kg of peanut cake, 9 kg of lignite, and 0.015 kg of composting starter, and after crushing, stack and ferment at room temperature for two weeks (or use fermentation equipment to ferment, keep the temperature at 45°C-60°C, and the humidity at 60%- 70%, the fermentation time can be shortened to 24-72 hours), after that, dry it in the air for three days (or dry it with a drying machine), become a dry product of about 35 kg (organic matter ≥ 70%), and carry out secondary crushing , through a 100-mesh sieve.

[0024] Soak 9 kg of attapulgite in 2.5 mol / L hydrochloric acid for 24 hours, bake at 120°C until constant weight, and crush it for later use. Add 24 kg of cornstarch to distilled water, gelatinize at 95°C for 30 minutes, cool down to 40°C, add 9 kg of attapulgite, 35 kg of organic matter, 0.9 kg of initiator potassium persulfate, 60 kg of acrylamide, 0.25 kg of cross-linking agent polyethylene glycol diglycidyl ether and 300 L of water, heate...

Embodiment 2

[0028]Crush 50 grams of wood bran, 750 grams of bean cake, 175 grams of lignite, and 0.35 grams of compost starter, and stack them at room temperature for two weeks (or use fermentation equipment to ferment, keep the temperature at 45°C-60°C, and the humidity at 60%-70%) , the fermentation time can be shortened to 24-72 hours), and then dried in the air for three days (or dried by a drying mechanism), and become a dry product with about 800 grams, which is crushed twice and passed through a 100-mesh sieve.

[0029] Soak 400 grams of attapulgite in hydrochloric acid with a concentration of 2.8 mol / L for 24 hours, bake at 120°C until constant weight, and crush it for later use.

[0030] Add 700 grams of cornstarch into distilled water, gelatinize at 95°C for 30 minutes, cool down to 40°C, add 400 grams of attapulgite, 800 grams of organic matter, 30 grams of initiator ammonium sulfate, 600 grams of acrylamide, 10 gram cross-linking agent polyethylene glycol diglycidyl ether and ...

Embodiment 3

[0034] Crush 25 kg of wood bran, 375 kg of bean cake, 90 kg of peat, and 0.2 kg of yeast, and stack them at room temperature for two weeks (or use fermentation equipment to ferment, keep the temperature at 45°C-60°C, humidity at 60%-70%, and ferment The time can be shortened to 24-72 hours), and then dried in the air for three days (or dried with a dryer), becoming a dry product of about 400 kilograms, which is pulverized for the second time and passed through a 100-mesh sieve.

[0035] Soak 200 kg of attapulgite in hydrochloric acid with a concentration of 2.5 mol / L for 24 hours, bake at 120°C to constant weight, and grind it for later use.

[0036] Add 370 kg of cornstarch into distilled water, gelatinize at 95°C for 30 minutes, cool down to 40°C, add 200 kg of attapulgite, 400 kg of organic matter, 15 kg of initiator ammonium sulfate, 300 kg of acrylamide, 5 Kilogram cross-linking agent polyethylene glycol diglycidyl ether and 3 cubic meters of water, raise the temperature ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com