Polyethylene ball valve air tightness detection device

A detection device, polyethylene ball technology, applied in the direction of measuring device, fluid tightness test, liquid tightness measurement using liquid/vacuum degree, etc., can solve problems such as low efficiency, dirty environment, etc., and achieve a high degree of automation , environmental protection, strong reusability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The technical solutions of the present invention will be further specifically described below through examples.

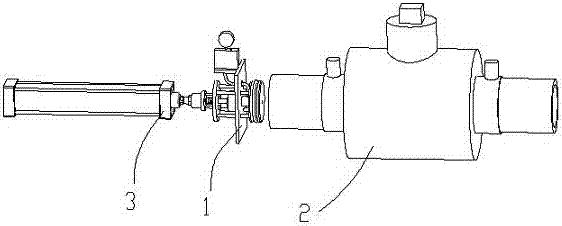

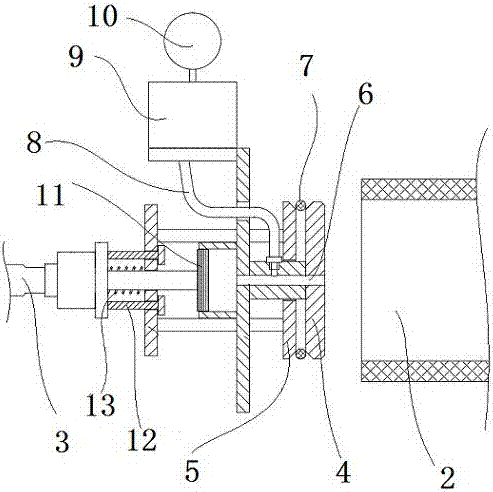

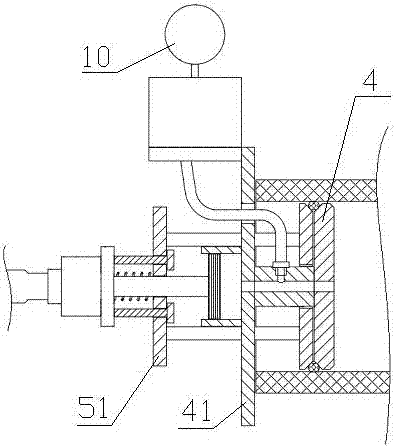

[0026] In this embodiment, a polyethylene ball valve airtightness detection device includes a detection body 1, and the detection body 1 has its own driving device 3, see figure 1 , the detection body 1 is provided with two pushers connected in series coaxially. The externally expanded sealing body 7 is composed of two pressure plates and the sealing body 7 to jointly form a sealing head that cooperates with the inner hole of the ball valve 2 to be tested, such as figure 2 As shown, the head is provided with an inflatable channel 6, and one end of the inflatable channel 6 communicates with the inflatable cylinder body; the inflatable channel is also connected to a pressure gauge 10 through an air pipe 8, and an overpressure protection mechanism 9 is provided on the air pipe 8.

[0027] Specifically, the pressure plates that the push bodies connected in ser...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com