Process method for preparing wear-resisting extrusion roller sleeve through centrifugal casting

A technology of centrifugal casting and process method, which is applied in the field of centrifugal casting to prepare wear-resistant squeeze roll sleeves, can solve the problems of easy peeling of ceramic particles, affect performance, uneven distribution of ceramic particles, etc., to improve the overall composite effect and facilitate the Splicing and fixing, improving the effect of metal liquid organization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] The centrifugal casting process method for preparing wear-resistant extrusion roller sleeve, the specific steps are as follows:

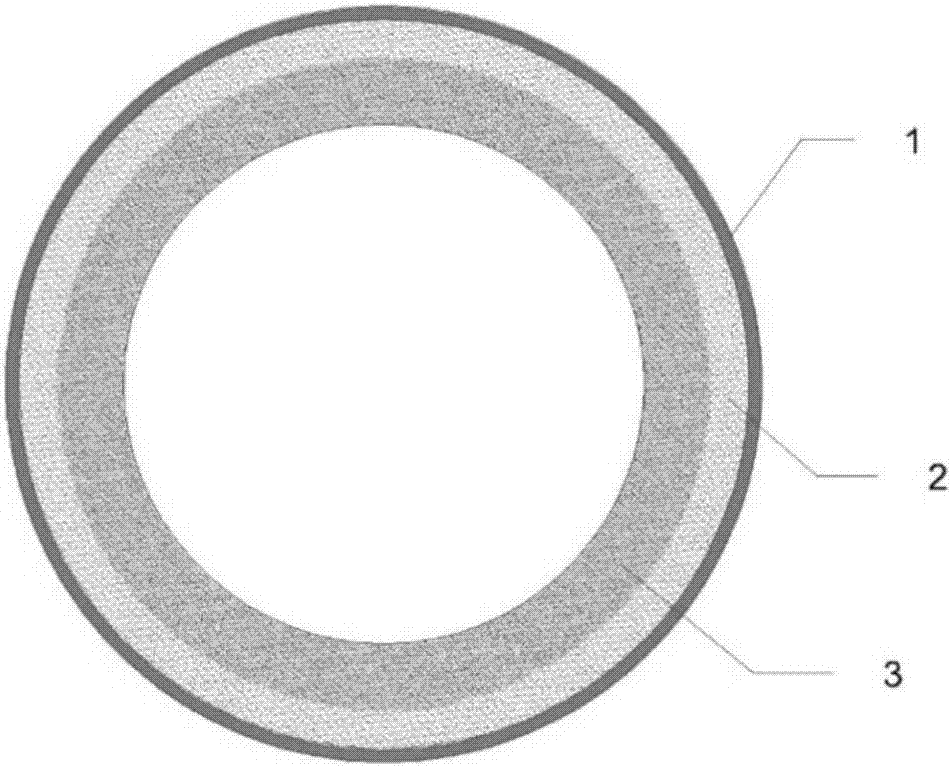

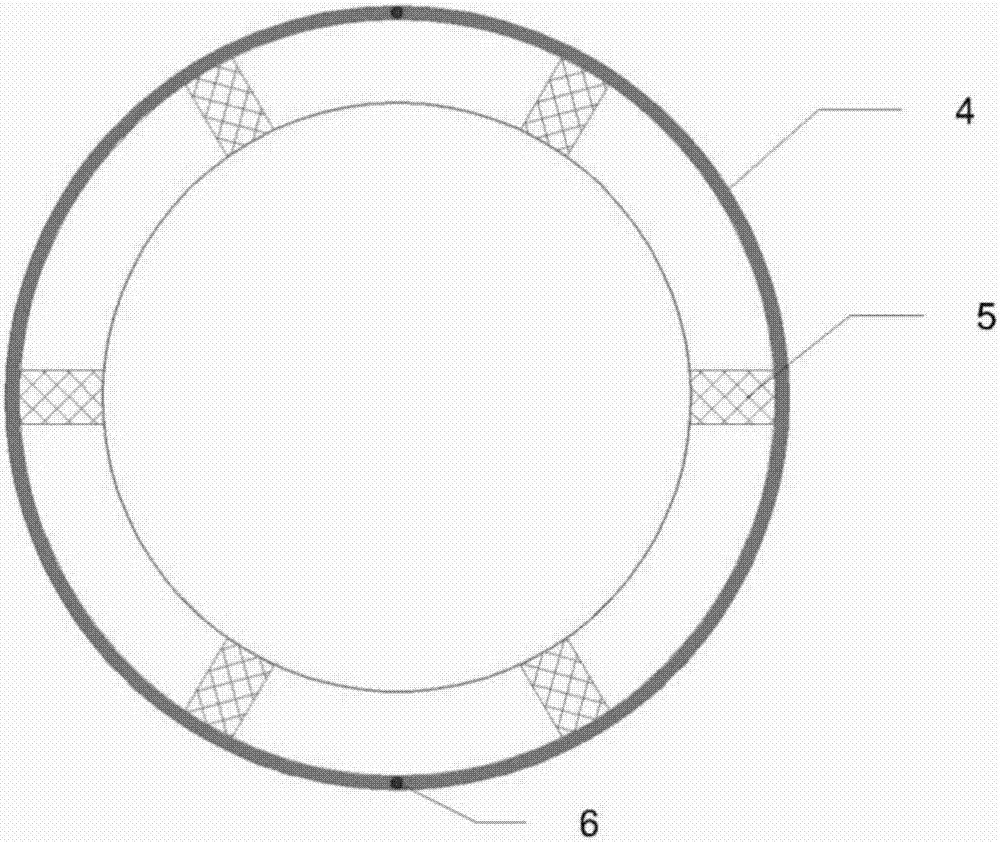

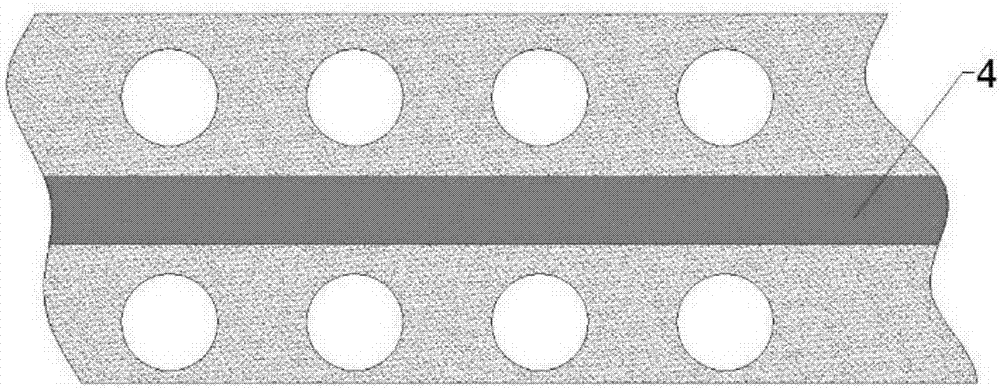

[0033] 1. First, place the prepared skeleton in a ring mold and fix it, fully mix 60-mesh WC ceramic particles with water glass at a mass ratio of 100:10, and fill the outer layer of the mold, which accounts for 1 / 5 of the volume of the blank; After mixing 120 mesh ZTA with water glass, iron powder and silicon powder in a mass ratio of 100:10:20:5, it is filled into the inner layer of the mold, which accounts for 4 / 5 of the blank volume. At this time, the skeleton support net is wrapped by ceramic particles Inside, drying and demoulding are performed to obtain a honeycomb annular preform blank with a skeleton. Among them, iron powder and silicon powder are 300 mesh, and the modulus of water glass is 2.

[0034] 2. The inlaid holes on the preform skeleton are inlaid with inlaid columns for splicing to obtain a billet in the shape of a roller ...

Embodiment 2

[0037] The centrifugal casting process method for preparing wear-resistant extrusion roller sleeve, the specific steps are as follows:

[0038] 1. First, place the prepared skeleton in a ring mold to fix it, fully mix 80-mesh WC ceramic particles with water glass in a mass ratio of 100:8, and then fill the outer layer of the mold, which accounts for 1 / 10 of the volume of the entire blank ; After mixing 200 mesh ZTA with water glass, iron powder, nickel powder, and tungsten powder in a mass ratio of 100:12:30:5:10, it is filled into the inner layer of the mold, which accounts for 9 / 10 of the blank volume. At this time, the skeleton The support net is wrapped in ceramic particles, and is dried and demolded to obtain a ring-shaped preform blank with honeycomb holes. Among them, iron powder and silicon powder are 500 mesh, and the modulus of water glass is 2.5.

[0039] 2. The annular preforms are spliced through the inlaid holes and inlaid columns on the skeleton, and the gap ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com