A high temperature resistant low modulus thermally conductive silicone material and preparation method thereof

A low-modulus, silicone technology, applied in heat exchange materials, chemical instruments and methods, etc., can solve the problems of rapid production and construction of thermally conductive gaskets, increase heat transfer resistance, and reduce heat dissipation effect, and achieve cross-linking. The point density and distribution are controllable, the effect of changing the surface polarity and reducing the viscosity of the material

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

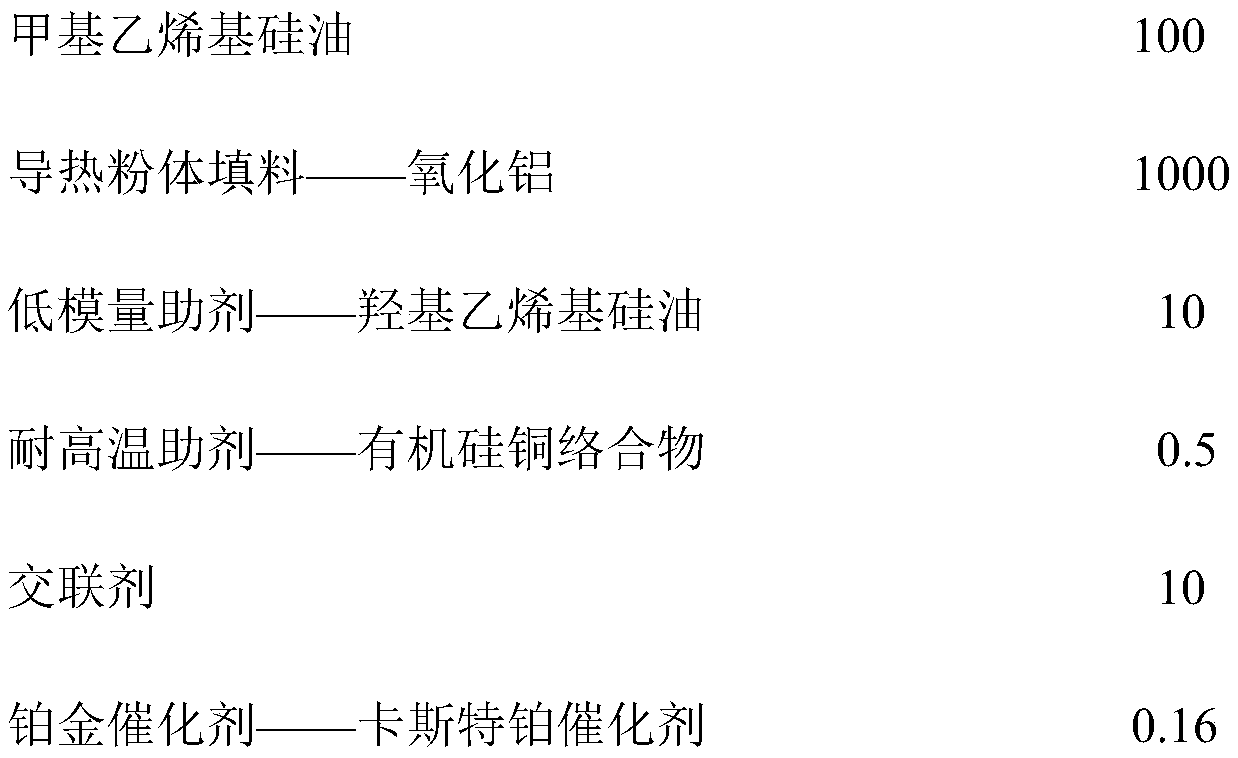

[0033] Example 1 High temperature resistant low modulus thermally conductive silicone material

[0034] The heat-resistant low-modulus thermally conductive silicone material includes the following raw materials in parts by mass:

[0035]

[0036] The viscosity of methyl vinyl silicone oil is 500 cp; the alumina is spherical, with a median diameter of 5 μm; the viscosity of hydroxyvinyl silicone oil is 5 cp; the crosslinking agent consists of 4 parts of terminal hydrogen-containing silicone oil and 6 parts of side hydrogen-containing silicone oil; The content of platinum in the ster platinum catalyst is 5000ppm.

[0037] A method for preparing a heat-resistant low-modulus heat-conducting silicone material, comprising the following steps:

[0038] S1 Put the silicone oil (methyl vinyl silicone oil) into the disperser, then add the thermal conductive powder filler (aluminum oxide) and low modulus additive (hydroxyl vinyl silicone oil) in batches, stir and mix evenly;

[0039...

Embodiment 2

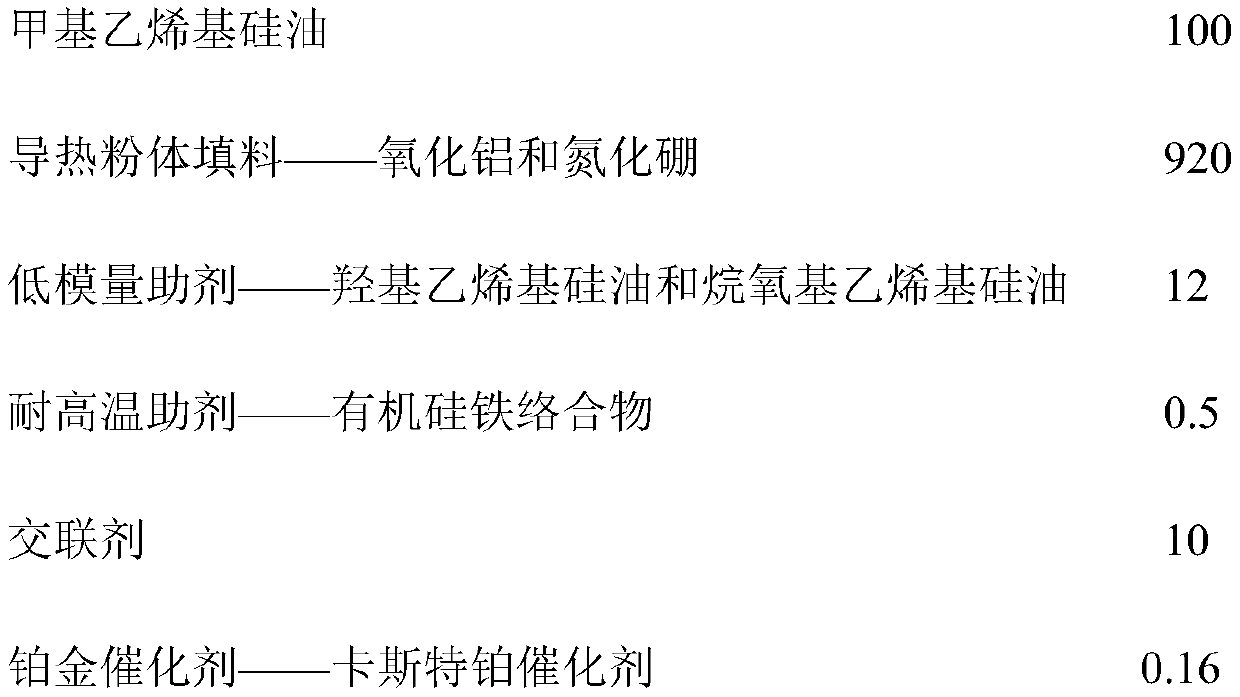

[0042] Example 2 High temperature resistant low modulus thermally conductive silicone material

[0043] The heat-resistant low-modulus thermally conductive silicone material includes the following raw materials in parts by mass:

[0044]

[0045] The viscosity of methyl vinyl silicone oil is 500 cp; the thermal conductive powder filler is composed of 900 parts of alumina and 20 parts of boron nitride, the alumina is spherical, the median diameter is 20 μm, and the median diameter of boron nitride is 2 μm; low modulus The volume assistant is composed of hydroxy vinyl silicone oil and alkoxy vinyl silicone oil in a mass ratio of 6:1, and the viscosity is 15cp; the crosslinking agent is composed of 4 parts of terminal hydrogen-containing silicone oil and 6 parts of side hydrogen-containing silicone oil; The platinum content in the platinum catalyst is 5000ppm.

[0046] The preparation method of the high-temperature-resistant low-modulus heat-conducting silicone material is si...

Embodiment 3

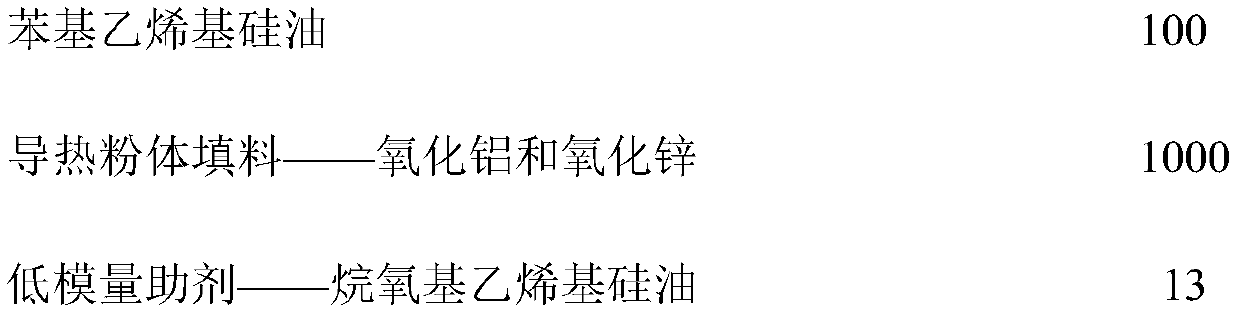

[0047] Example 3 High temperature resistant low modulus thermally conductive silicone material

[0048] The heat-resistant low-modulus thermally conductive silicone material includes the following raw materials in parts by mass:

[0049]

[0050]

[0051] The viscosity of phenylvinyl silicone oil is 1000 cp; the thermal conductive powder filler is composed of 800 parts of alumina and 200 parts of zinc oxide, the alumina is spherical, the median diameter is 10 μm, and the median diameter of zinc oxide is 1.5 μm; The viscosity of vinyl silicone oil is 10cp; the crosslinking agent is composed of 3 parts of terminal hydrogen-containing silicone oil and 6 parts of side hydrogen-containing silicone oil; the content of platinum in Castel platinum catalyst is 5000ppm.

[0052] The preparation method of the high-temperature-resistant low-modulus heat-conducting silicone material is similar to the first embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com