Preparation method of metal-doped zinc oxide liquid-phase homogenous-dispersed body

A technology of metal doping and uniform dispersion, applied in zinc oxide/zinc hydroxide, nanotechnology for materials and surface science, nanotechnology, etc., to achieve uniform dispersion, simple method, and good crystallinity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] a) Weigh 6.15g of zinc acetate dihydrate [Zn(CH 3 COO) 2 2H 2 O], 0.2g aluminum nitrate nonahydrate [Al(NO 3 ) 3 9H 2 O] add in the nitrogen bottle, and add 275mL methyl alcohol and dissolve it;

[0037] b) Weigh 2.4g of potassium hydroxide (KOH) into 125mL of methanol, and dissolve it by ultrasonic;

[0038] c) under the protection of nitrogen, the solution obtained in step a) was heated to 60° C. and stirred vigorously;

[0039] d) Put the solution obtained in step b) into a constant-pressure dropping funnel, and drop KOH (aq) into the solution obtained in step a) drop by drop at 60° C., and finish dropping in about 45 minutes;

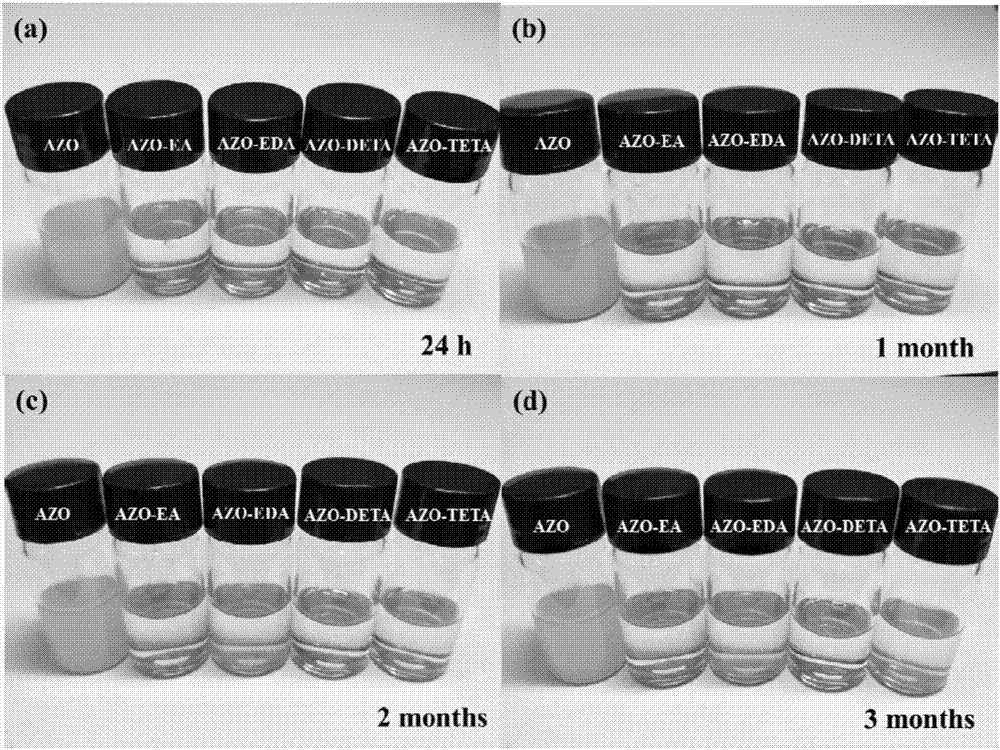

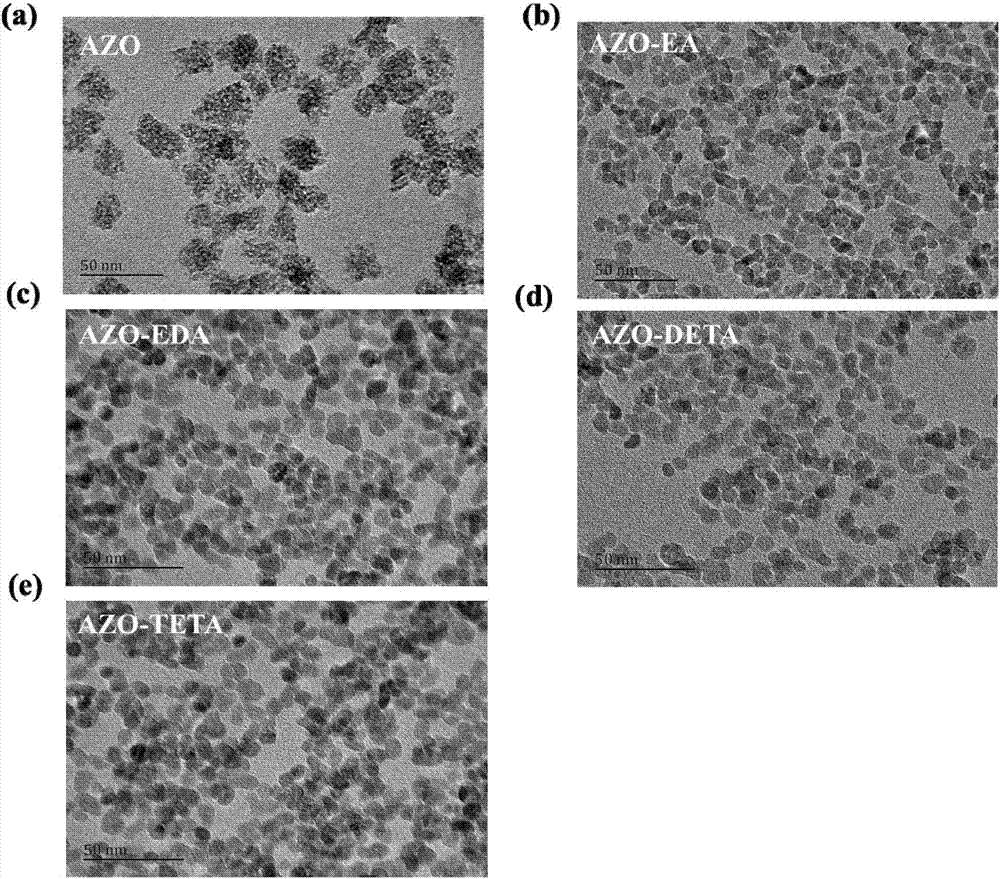

[0040] e) Refluxing the mixed solution obtained in step d) at 80° C. for 3.0 h to obtain a light blue translucent solution, which is the prepared aluminum-doped zinc oxide nanoparticle solution;

[0041] f) Centrifuge the light blue solution obtained in step e), take the jelly-like substance at the bottom of the centrifuge tube, and af...

Embodiment 2

[0044]

[0045] a) Weigh 6.15g of zinc acetate dihydrate [Zn(CH 3 COO) 2 2H 2 O], 0.2g aluminum nitrate nonahydrate [Al(NO 3 ) 3 9H 2 O] add in the nitrogen bottle, and add 275mL methyl alcohol and dissolve it;

[0046] b) Weigh 2.4g of potassium hydroxide (KOH) into 125mL of methanol, and dissolve it by ultrasonic;

[0047] c) under the protection of nitrogen, the solution obtained in step a) was heated to 60° C. and stirred vigorously;

[0048] d) Put the solution obtained in step b) into a constant-pressure dropping funnel, and drop KOH (aq) into the solution obtained in step a) drop by drop at 60° C., and finish dropping in about 45 minutes;

[0049] e) Refluxing the mixed solution obtained in step d) at 80° C. for 3.0 h to obtain a light blue translucent solution, which is the prepared aluminum-doped zinc oxide nanoparticle solution;

[0050] f) Centrifuge the light blue solution obtained in step e), take the jelly-like substance at the bottom of the centrifuge ...

Embodiment 3

[0053]

[0054] a) Weigh 1.23g of zinc acetate dihydrate [Zn(CH 3 COO) 2 2H 2 O], 0.04g aluminum nitrate nonahydrate [Al(NO 3 ) 3 9H 2 O] add in the nitrogen bottle, and add 55mL methanol and dissolve it;

[0055] b) Weigh 0.48g of potassium hydroxide (KOH) into 25mL of methanol, and dissolve it by ultrasonic;

[0056] c) under the protection of nitrogen, the solution obtained in step a) was heated to 60° C. and stirred vigorously;

[0057] d) Put the solution obtained in step b) into a constant pressure dropping funnel, and drop KOH(aq) into the solution obtained in step a) at 60°C, and drop it in about 20 minutes;

[0058] e) Refluxing the mixed solution obtained in step d) at 80° C. for 2.5 hours to obtain a light blue translucent solution, which is the prepared aluminum-doped zinc oxide nanoparticle solution;

[0059] f) Centrifuge the light blue solution obtained in step e), take the jelly-like substance at the bottom of the centrifuge tube, and after the centri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com