Modified magnetic sludge biological carbon and preparation method and applications thereof

A biochar and magnetic technology, applied in the field of materials, can solve the problems of poor adsorption and removal ability, limited adsorption sites, secondary pollution of water body, etc., achieve strong removal ability, many adsorption sites, and reduce production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

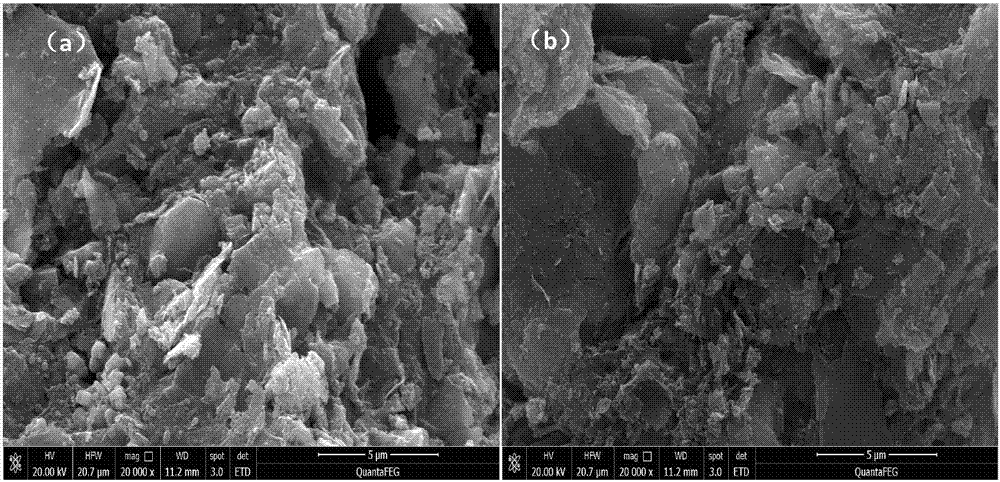

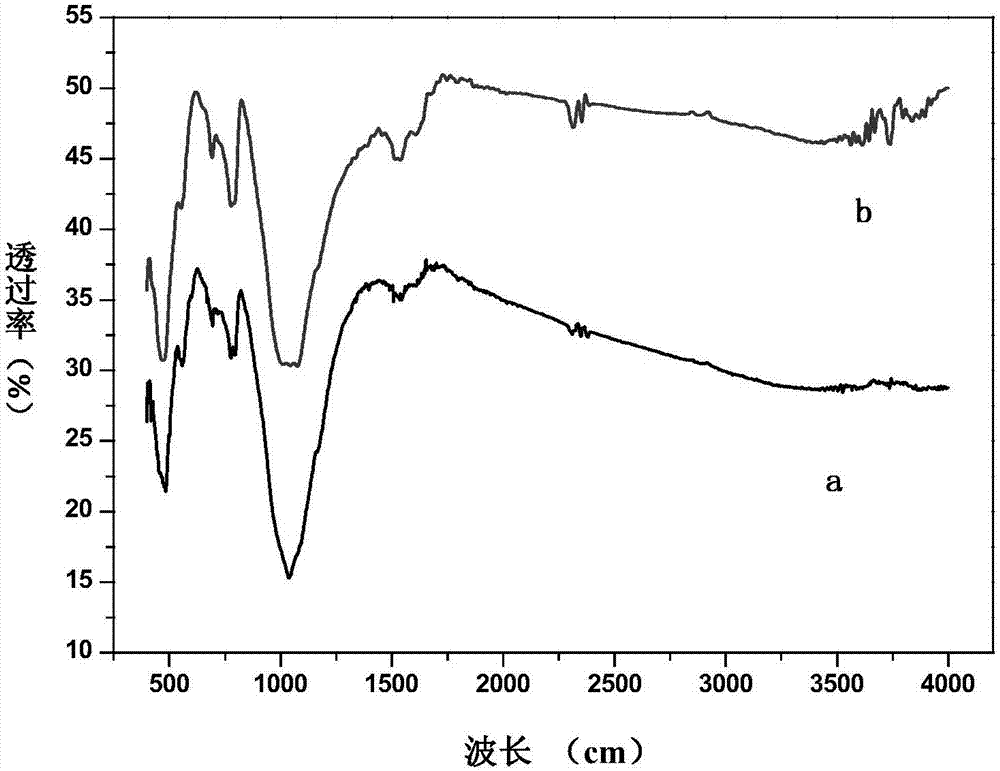

[0046] A modified magnetic sludge biochar is prepared from residual sludge after carbonization, alkali modification and acid modification. The modified magnetic sludge biochar includes biochar and iron compound particles, wherein the iron compound particles are γ-iron trioxide particles and iron oxyhydroxide particles.

[0047] In this embodiment, the atomic percentage of iron in the modified magnetic sludge biochar is 1.05%.

[0048] In this example, the specific surface area of the modified magnetic sludge biochar is 202m 2 / g, the pore volume is 0.2563m 3 / g.

[0049] A method for preparing the modified magnetic sludge biochar of this embodiment described above includes the following steps:

[0050] (1) Pretreatment of surplus sludge: the surplus sludge is dried, crushed, and passed through a 120-mesh sieve to obtain powdery surplus sludge, which is used as a raw material for preparing magnetic sludge biochar.

[0051] (2) Preparation of magnetic sludge biochar: Put the powdery su...

Embodiment 2

[0066] A modified magnetic sludge biochar is basically the same as the modified magnetic sludge biochar of Example 1, except that the specific surface area and pore volume of the modified magnetic sludge biochar of Example 2 are 140.469m, respectively. 2 / g and 0.1778m 3 / g.

[0067] A method for preparing the modified magnetic sludge biochar of this embodiment described above includes the following steps:

[0068] (1) Pretreatment of surplus sludge: the surplus sludge is dried, crushed, and passed through a 120-mesh sieve to obtain powdery surplus sludge, which is used as a raw material for preparing magnetic sludge biochar.

[0069] (2) Preparation of magnetic sludge biochar: Put the powdery surplus sludge obtained in step (1) in a tube furnace, and under the protection of flowing nitrogen, the temperature rises from room temperature at a heating rate of 5°C / min It is carbonized at a constant temperature of 800°C for 2 hours, and taken out after natural cooling to obtain magnetic s...

Embodiment 3

[0074] A modified magnetic sludge biochar, which is basically the same as the modified magnetic sludge biochar of Example 1, except that the specific surface area and pore volume of the modified magnetic sludge biochar of Example 3 are 180.917m respectively. 2 / g and 0.2265m 3 / g.

[0075] A method for preparing the modified magnetic sludge biochar of this embodiment is basically the same as the preparation method of Example 1, except that the step (3.2) of the preparation method of Example 3 uses a commercially available glacial acetic acid solution (Concentration is 17mol / L) for acid modification.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com