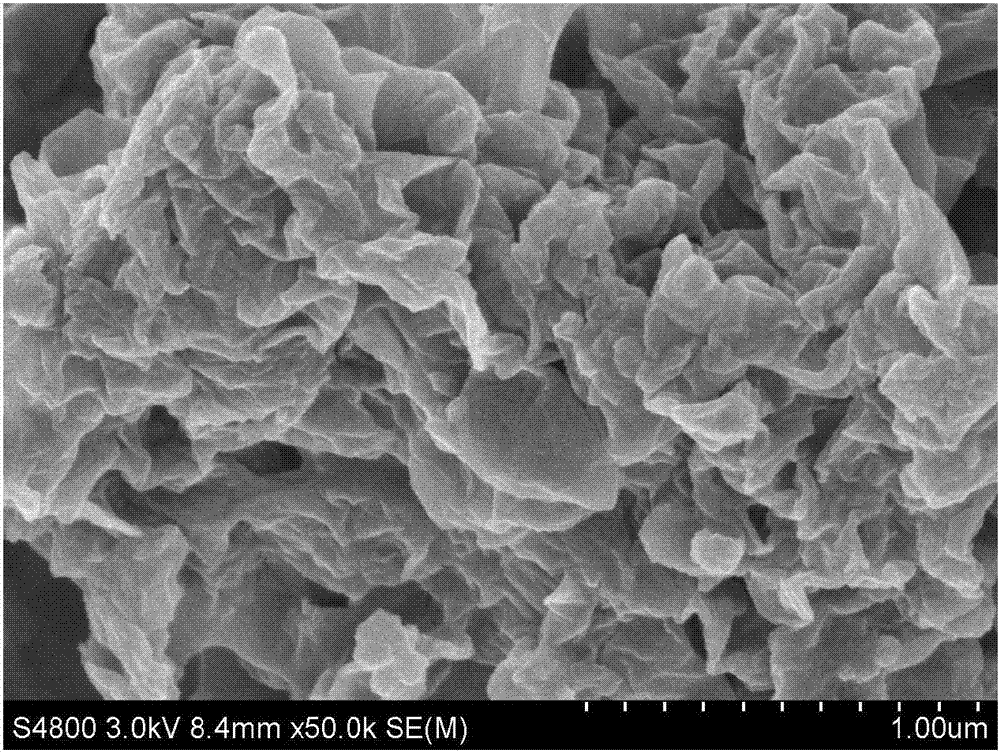

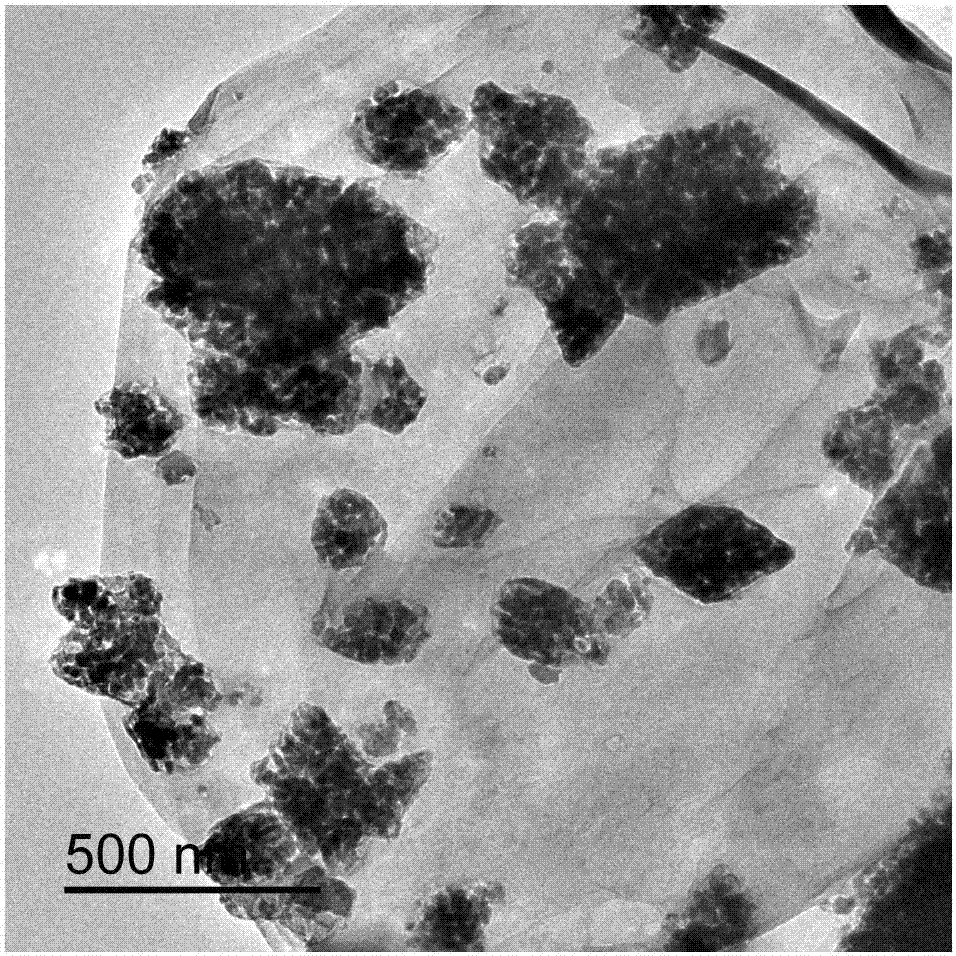

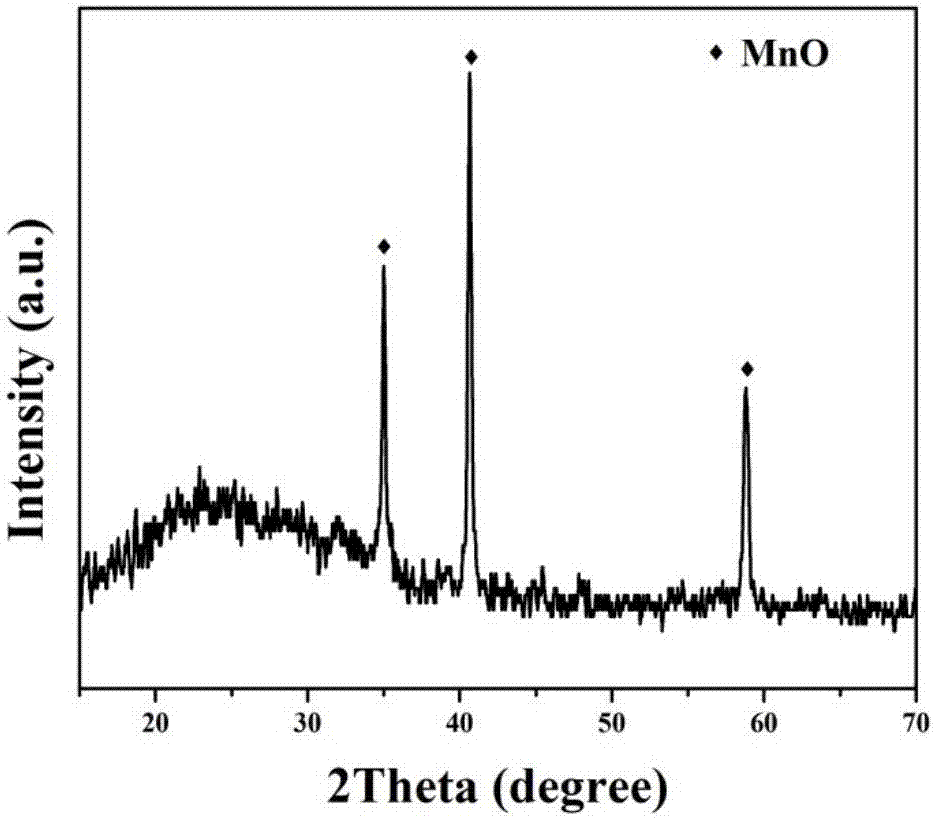

Preparation method of carbon-coated-manganese oxide/nitrogen-doped reduced graphene oxide anode material for lithium ion battery

A lithium-ion battery, manganese monoxide technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of waste, large consumption of graphene oxide, etc., and achieve the effect of improving conductivity and improving cycle stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] 1) adding manganese acetate into water and stirring at room temperature to prepare a manganese acetate solution with a mass fraction of 2.5%;

[0026] 2) Take 30mg of graphene oxide and add it to 40ml of manganese acetate solution, stirring and ultrasonication at 60W power for 1h alternately for 3 times, and the dispersion is uniform;

[0027] 3) Transfer the mixture obtained in step 2) to a reactor, and conduct a microwave hydrothermal reaction at 120° C. for 1 h;

[0028] 4) The microwave hydrothermal reaction product obtained in step 3) was evenly mixed with 1.2 g of sucrose, and transferred to a polytetrafluoroethylene reactor for hydrothermal reaction at 150° C. for 12 hours;

[0029] 5) Filter the hydrothermal reaction product obtained in step 4), alternately wash with ethanol, deionized water, and acetone, and dry;

[0030] 6) The product obtained in step 5) is heat-treated at 500° C. for 2 hours in a mixed atmosphere furnace in which argon and ammonia are mixed...

Embodiment 2

[0036] 1) adding manganese acetate into water and stirring at room temperature to prepare a manganese acetate solution with a mass fraction of 3.5%;

[0037] 2) Take 30mg of graphene oxide and add it to 50ml of manganese acetate solution, stirring and ultrasonication at 70W power for 1h alternately for 4 times, and the dispersion is uniform;

[0038] 3) Transfer the mixture obtained in step 2) to a reactor, and conduct a microwave hydrothermal reaction at 150° C. for 2 hours;

[0039] 4) Mix the microwave hydrothermal reaction product obtained in step 3) with 2.0 g of sucrose evenly, and transfer it to a polytetrafluoroethylene reactor for hydrothermal reaction at 180°C for 16 hours;

[0040] 5) Filter the hydrothermal reaction product obtained in step 4), alternately wash with ethanol, deionized water, and acetone, and dry;

[0041] 6) The product obtained in step 5) is heat-treated at 600° C. for 1 h in a mixed atmosphere furnace in which argon and ammonia are mixed at a vo...

Embodiment 3

[0043] 1) adding manganese acetate into water and stirring at room temperature to prepare a manganese acetate solution with a mass fraction of 4.5%;

[0044] 2) Take 50mg of graphene oxide and add it to 45ml of manganese acetate solution, stirring and ultrasonication at 80W power for 1h alternately for 5 times, and the dispersion is uniform;

[0045]3) Transfer the mixture obtained in step 2) to a reaction kettle, and conduct a microwave hydrothermal reaction at 180° C. for 3 hours;

[0046] 4) Mix the microwave hydrothermal reaction product obtained in step 3) with 2.5 g of sucrose evenly, and transfer it to a polytetrafluoroethylene reactor for hydrothermal reaction at 180°C for 18 hours;

[0047] 5) Filter the hydrothermal reaction product obtained in step 4), alternately wash with ethanol, deionized water, and acetone, and dry;

[0048] 6) The product obtained in step 5) is heat-treated at 700° C. for 3 hours in a mixed atmosphere furnace in which argon and ammonia are mi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com