A method for improving hot forming and service performance of mg-al-zn series magnesium alloy

A mg-al-zn, magnesium alloy technology, applied in the field of deformation heat treatment, improving the hot forming and service performance of Mg-Al-Zn series magnesium alloy, can solve the problem of poor comprehensive mechanical properties, hot forming and service performance of cast magnesium alloy Good, damage to alloy strength and ductility, etc., to achieve outstanding strengthening effect, promote dynamic recrystallization process, and refine the alloy structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

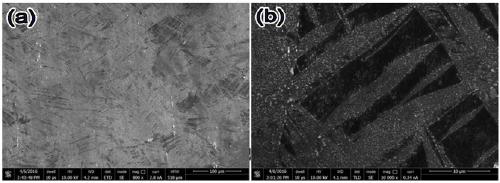

[0029] The as-cast AZ80 magnesium alloy was solution treated at 450°C for 12h, then bent and deformed at room temperature, then compressed and deformed to introduce twins, the cumulative deformation amount was 0.1 of the true strain, and then aged at 200°C for 2h, the obtained alloy structure is as attached figure 1 shown, from figure 1 It can be seen that the precipitated phases are finely dispersed and evenly distributed in the matrix. The alloy structure of only aging treatment is as attached figure 2 As shown, it can be seen that only the precipitated phase in the aging treatment specimen is in the form of coarse lamellar sheets, and the distribution is uneven. The room temperature tensile mechanical properties of the specimens subjected to deformation heat treatment and aging treatment alone are shown in Table 1. The tensile strength of specimens subjected to deformation heat treatment is 345 MPa, which is 56 MPa higher than that of specimens with only aging treatment; ...

Embodiment 2

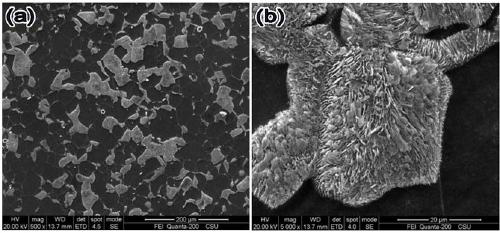

[0034] The as-cast AZ61 magnesium alloy was solution treated at 430°C for 10 hours, then pre-compressed and deformed at 300°C, the deformation amount was 0.2 of the true strain, and then aged at 180°C for 2 hours. Figure 5 As shown, it can be seen from the figure that a large number of low-angle grain boundaries appear in the original grains of the alloy after high-temperature pre-deformation, and after subsequent aging treatment, fine precipitates precipitate on the low-angle grain boundaries.

Embodiment 3

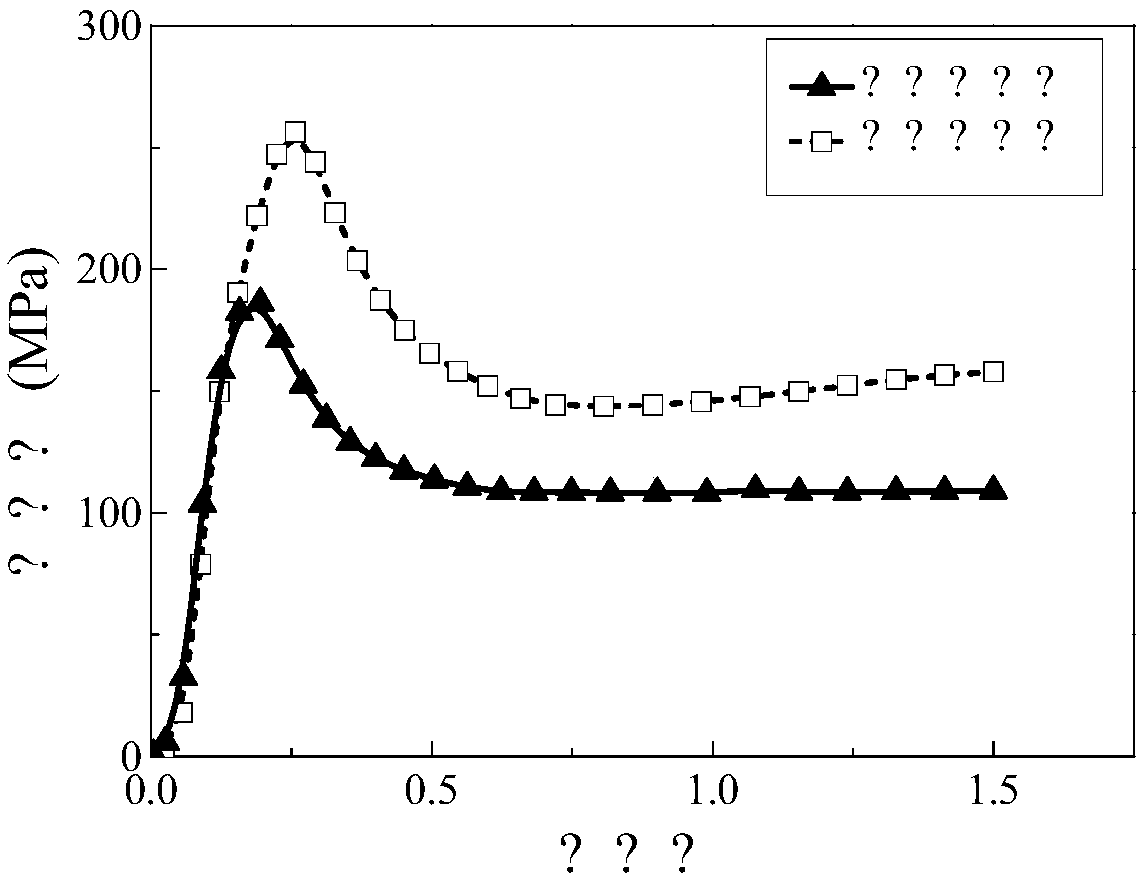

[0036] The as-cast AZ91 magnesium alloy was solution treated at 450°C for 12 hours, then pre-stretched at 150°C to introduce twins, and the deformation amount was 0.05 of the true strain, and then aged at 220°C for 30 minutes. Figure 6 As shown, it can be found that the fine dispersed precipitates are uniformly distributed in the AZ91 magnesium alloy matrix. The creep properties of deformation heat treatment specimens and aging treatment specimens at 200°C and 80MPa are shown in the attached Figure 7 As can be seen from the figure, it can be found that the creep deformation and creep rate of the specimens with thermomechanical treatment are much lower than those with only aging treatment, and the steady-state creep rates of specimens with thermomechanical treatment and aging treatment only are 2.7×10 -8 the s -1 , 7.5×10 -8 the s -1 , indicating that the creep resistance of the alloy has been effectively improved after deformation heat treatment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| fatigue limit | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com