Preparation process of soft-soft contact-type bionic joint

A technology of bionic joints and preparation technology, which is applied in the field of bionic joints, can solve the problems of aseptic wear and loosening of artificial joints, and achieve the effects of solving wear and aseptic loosening, reducing impact, and absorbing shocks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0036] The specific steps of a soft-soft contact bionic joint preparation process are as follows:

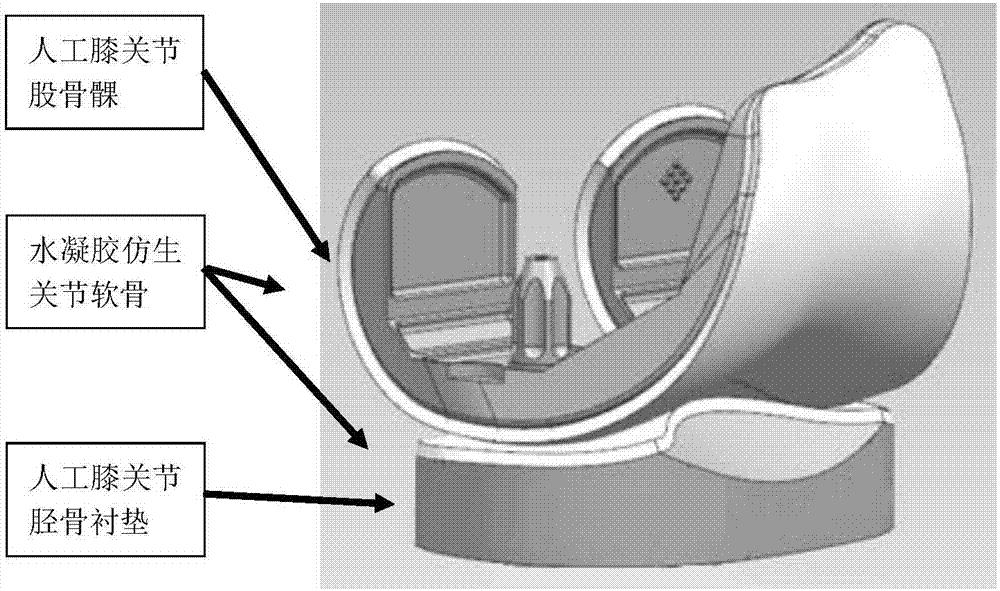

[0037] 1) According to the size of the artificial knee joint and the artificial hip joint, the medical polyethylene bar is processed into the artificial knee joint femoral condyle, the artificial knee joint tibia pad, the artificial hip joint femoral head, and the artificial hip joint acetabulum.

[0038] 2) Use acetone, ethanol and deionized water to thoroughly clean the medical polyethylene joint parts (artificial knee femoral condyle, artificial knee tibia pad, artificial hip femoral head, artificial hip acetabulum) in sequence; The medical polyethylene joint parts were soaked in dichromic acid oxidizing solution (potassium dichromate and concentrated sulfuric acid by mass percentage 1:4), and placed in a water bath at 75 ° C for 10 min, taken out and washed with a large amount of deionized water; then Treat the surface of medical polyethylene joint parts with oxygen ion beam...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com