Preparation method of enteric-coated soft capsules

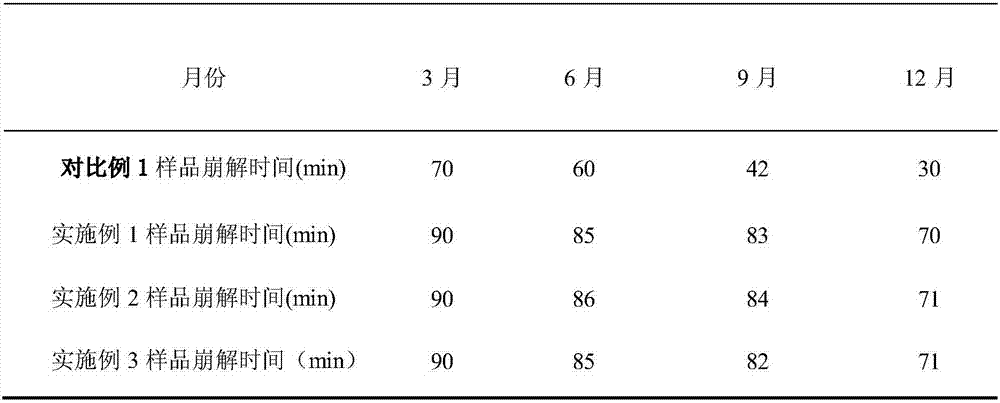

A technology of enteric-coated soft capsules and soft capsule shells, which is applied in the field of preparation of enteric-coated soft capsules, can solve the problems of easy erosion of rubber skin by liquid medicine, easy oil leakage, and limited ability of soft capsules to resist extrusion and collision, etc. Achieve the effect of increasing shelf life, increasing disintegration time and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] A kind of preparation method of enteric-coated soft capsule, the mass percentage of each group of raw materials is as follows:

[0040] Contents: 2% garlic oil, 98% fish oil; stir and mix evenly in a dispensing tank;

[0041] Coating solution: 15% acrylic resin polymer, 2.25% citrate triester, 1.05% propylene glycol, 1.7% talcum powder, 80% purified water; mix evenly in a container.

[0042] Rubber components: gelatin 50%, glycerin 17%, water 33%.

[0043] The preparation steps are as follows:

[0044] Weigh glycerin and water according to the ratio, put them into the plastic tank, turn on the heating tank and raise the temperature to 75°C, then add the prepared coating solution, stir evenly, add gelatin, vacuum pressure -0.06~-0.7MPa, keep the pressure Sol, and then vacuumize the glue to make the glue free of bubbles (vacuum pressure -0.8MPa); then, let the glue stand at 65°C for about 2 hours, and the viscosity is 12000Pa. The glue solution of S is measured at 65°C...

Embodiment 2

[0048] A kind of preparation method of enteric-coated soft capsule, the mass percentage of each group of raw materials is as follows:

[0049] Softgel contents: 18 / 12 fish oil (EPA18 / DHA12) 100%

[0050] Coating liquid: 13% of acrylic resin polymer, 3.25% of citrate triester, 1.05% of propylene glycol, 2% of talcum powder, 80.7% of purified water, and 1% of absolute ethanol.

[0051] Rubber components: 45% gelatin, 17% glycerin, 38% water.

[0052] The preparation steps are as follows:

[0053] Glue configuration: Weigh glycerin and water according to the ratio, put them into the glue tank, turn on the heating tank to raise the temperature to 70°C, then add the prepared coating solution, stir well and add gelatin, vacuum pressure -0.07~- 0.8MPa, pressurize the sol, then vacuumize (vacuum pressure-0.9MPa) to make the glue free of bubbles, keep the glue at 65°C for 2.5h, and get a viscosity of 13000Pa. S glue. The resulting glue solution is used to form soft capsule shells i...

Embodiment 3

[0056] A kind of preparation method of enteric-coated soft capsule, the mass percentage of each group of raw materials is as follows:

[0057] Contents: VD3 oil 3%, 50 / 25 fish oil 97%; stir and mix well in a dispensing tank.

[0058] Coating liquid: 14% of acrylic resin polymer, 2.75% of citrate triester, 1.55% of propylene glycol, 2.7% of talc, 80% of purified water.

[0059] Rubber components: gelatin 40%, glycerin 19%, water 41%.

[0060] The preparation steps are as follows:

[0061] Glue configuration: Weigh glycerin and water according to the ratio, put them into the glue tank, turn on the heating tank to raise the temperature to 75°C, then add the prepared coating solution, stir well and add gelatin, vacuum pressure -0.07~- 0.8MPa, pressurize the sol, then vacuumize (vacuum pressure -0.85MPa) to make the glue free of bubbles, keep the glue at 65°C for 2 hours, and get a viscosity of 12500Pa. S glue.

[0062] Preparation of soft capsules: Use a 250-type automatic sof...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com