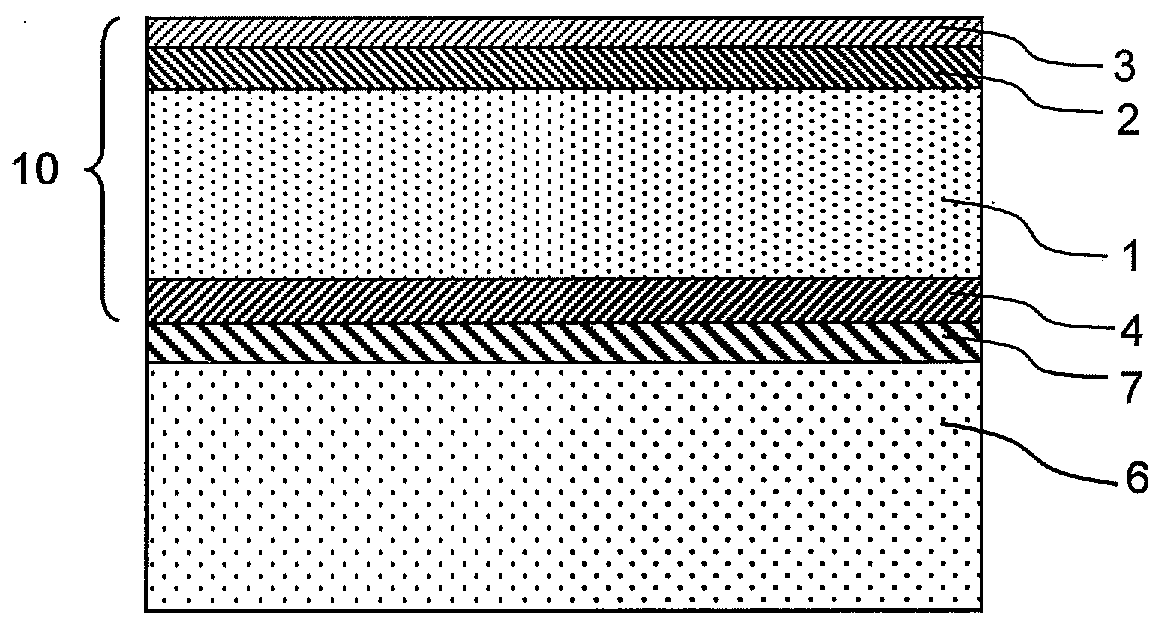

Transparent conductive film, transparent conductive film laminate, and touch panel

A technology of transparent conductive film and transparent conductive film, applied in the direction of conductive layer, non-metallic conductor, oxide conductor, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0104] (Preparation of Curable Resin Composition Adding Spherical Particles)

[0105] Acrylic spherical particles (products manufactured by Soken Chemical Co., Ltd.) containing 100 parts by weight of an ultraviolet curable resin composition (product name "UNIDIC (registered trademark) RS29-120" manufactured by DIC Corporation) and a mode particle diameter of 1.9 μm were prepared. Name "MX-180TA") 0.3 parts by weight of curable resin composition added spherical particles.

[0106] (Formation of cured resin layer)

[0107] The prepared curable resin composition containing spherical particles was coated on one side of a polycycloolefin film (trade name "ZEONOR (registered trademark)" manufactured by ZEON Japan) with a thickness of 35 μm and a glass transition temperature of 165°C to form coating layer. Then, the coating layer was irradiated with ultraviolet rays from the side where the coating layer was formed to form a second cured resin layer so as to have a thickness of 1.0 ...

Embodiment 2

[0115] Except in Example 1, a polycycloolefin film (trade name "ZEONOR (registered trademark)" manufactured by ZEON Japan) with a thickness of 50 μm was used as the transparent resin film, and spherical particles contained in the second cured resin layer were used. A transparent conductive film and a transparent conductive film laminate were produced by the same method as in Example 1, except that particles having a mode diameter of 0.8 μm were used and the thickness of the second cured resin layer was 0.5 μm.

Embodiment 3

[0117] In Example 1, the transparent conductive film and the transparent conductive film were formed in the same manner as in Example 1, except that after the optical adjustment layer was formed, the roll-to-roll method was annealed at 150° C. for 3 minutes to form a transparent conductive film. Sexual film laminate.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com