Open framework fluoride positive electrode material for potassium/sodium ion battery, and preparation method thereof

A technology for sodium ion batteries and cathode materials, which is applied in battery electrodes, secondary batteries, electrochemical generators, etc., can solve problems such as unfavorable cathode materials for sodium ion batteries, affecting cycle stability, etc., to improve the slow diffusion rate and increase the Cycling Stability and Rate Capability, Effect of Mitigating Lattice Volume Changes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

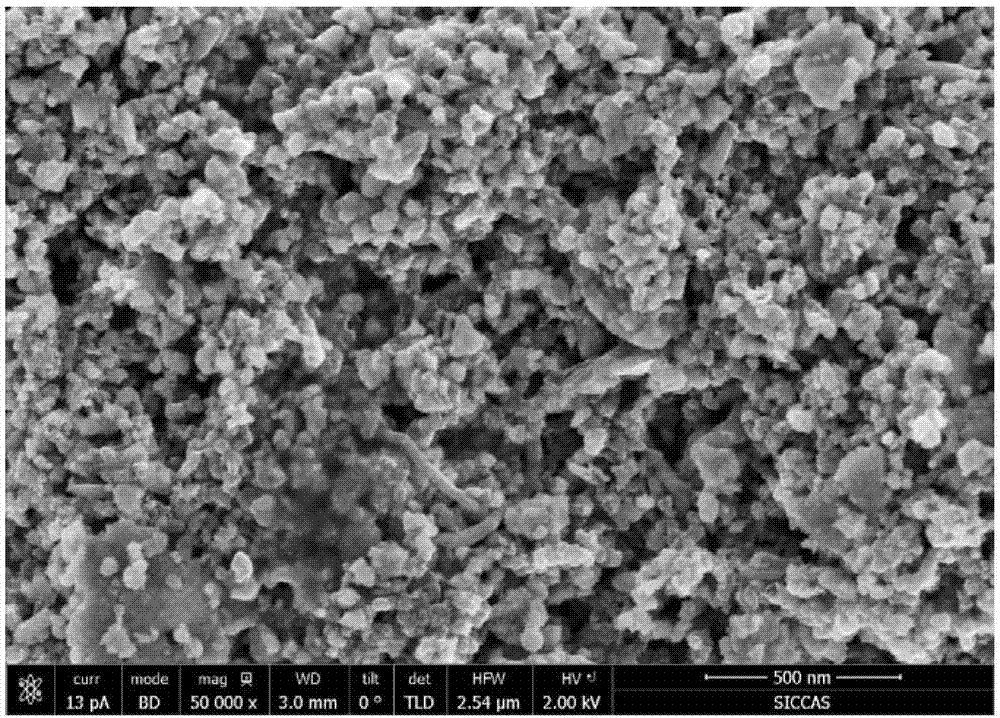

[0038] K x FeF 3 Mix the powder and conductive carbon black evenly, add a certain amount of solvent, and ball mill in an inert gas environment, then wash, centrifuge, and dry to obtain a composite positive electrode material based on the open-frame fluoride positive electrode material for potassium ion batteries. As long as the solvent meets the non-alcoholic anhydrous organic solvent, such as N-methylpyrrolidone, the quality of the solvent is K x FeF 3 400%-600% of the total mass of powder and conductive carbon black, preferably 500%. Wherein, the ball milling is performed at a rotating speed of 500-800r / min for 5-10 hours. As an example, each cycle of the ball milling reaction runs for 5-10min, stops for 15min, and has a total of 60 cycles. After the ball milling reaction finishes, the tank is cooled to room temperature and the tank is opened, and the sample is taken out with N-methylpyrrolidone (NMP) as a solvent, and washed by centrifugation. The powder is then dried. ...

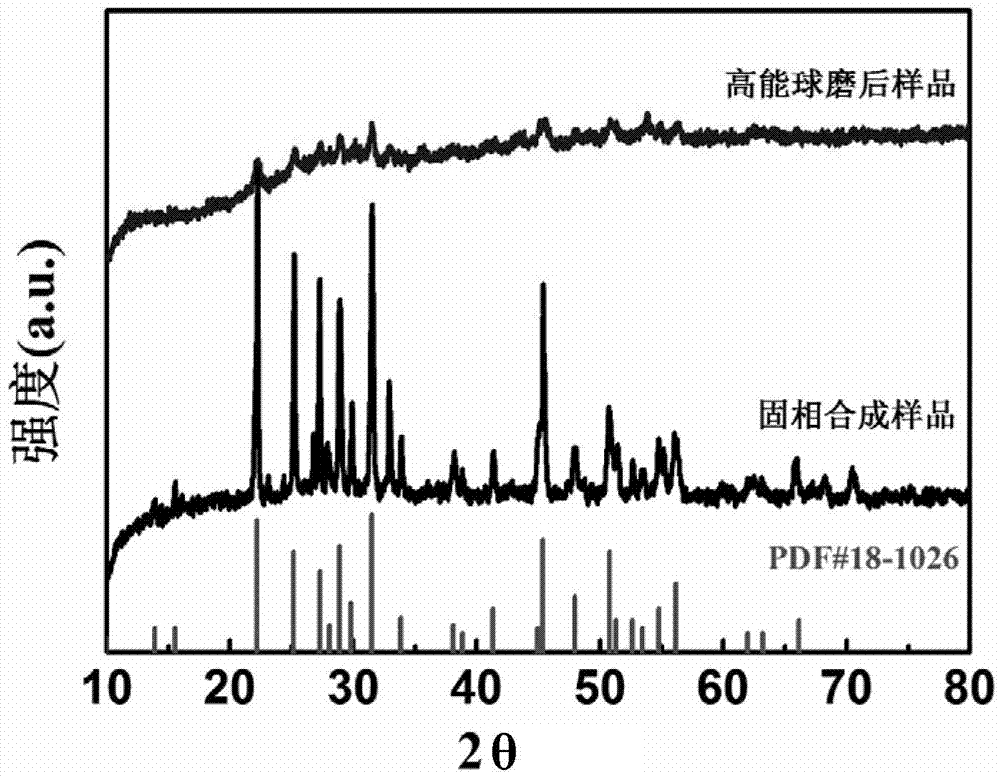

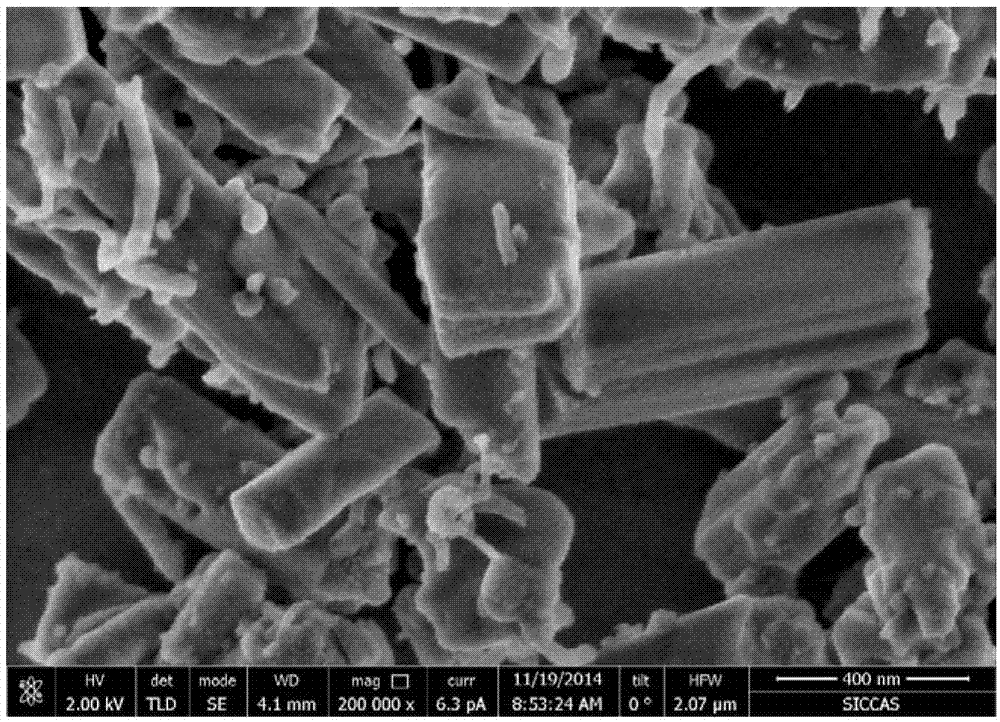

Embodiment 1

[0045] 1) Take KF, FeF 2 , FeF 3 0.33H 2 O is the precursor to prepare K 0.6 FeF 3 Cathode material:

[0046] Weigh 0.291g KF and 0.469g FeF according to the molar ratio of 1:1:1 2 , 0.594g FeF 3 0.33H 2 O. Grind the three materials in a mortar for 1 hour until well mixed. The mixed material was then pressed into a disc with a diameter of 10 mm under a pressure of 10 MPa. The pressed disc was put into a vacuum oven at 80°C to remove water, and after 12 hours, the disc was taken out and put into a glove box. The pressed discs were sealed into a stainless steel autoclave in an argon atmosphere glove box. The reaction kettle was taken out from the glove box and put into a tube furnace, and high-purity argon was introduced into the tube furnace to remove the air in the furnace tube. After ventilating for 2 hours, the reactor was heated under a specific program: the heating rate was 5°C / min, heated to 300°C and kept for 5 hours, and naturally cooled to room temperature a...

Embodiment 2

[0052] 1) Take KF, FeF 2 , FeF 3 ·3H 2 O is the precursor to prepare K 0.5 FeF 3 Cathode material:

[0053] Weigh 0.291g KF and 0.469g FeF according to the molar ratio of 1:1:1 2 , 0.834g FeF 3 ·3H 2 O. The three fluoride precursors were ground in a mortar for 1 h until well mixed. The mixed material was then pressed into a disc with a diameter of 10 mm under a pressure of 12 MPa. The pressed disc was put into a vacuum oven at 80°C to remove water, and after 12 hours, the disc was taken out and put into a glove box. The pressed discs were sealed into a stainless steel autoclave in an argon atmosphere glove box. The reaction kettle was taken out from the glove box and put into a tube furnace, and high-purity argon was introduced into the tube furnace to remove the air in the furnace tube. After ventilating for 2 hours, the reactor was heated under a specific program: the heating rate was 5°C / min, heated to 350°C and kept for 8 hours, and naturally cooled to room temp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com