Anti-freezing environmentally-friendly material yard and construction method

A stockyard and environmental protection technology, applied in large-capacity bulk material storage, protective buildings/shelters, loading/unloading, etc., can solve the problems of high heating costs, adverse effects on the environment and human health in bulk stockyards, Easy to pollute the environment, such as smog and haze weather, to save costs and land resources, prevent dust from flying and heat loss, and avoid dust pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments, but the protection scope of the present invention is not limited thereby.

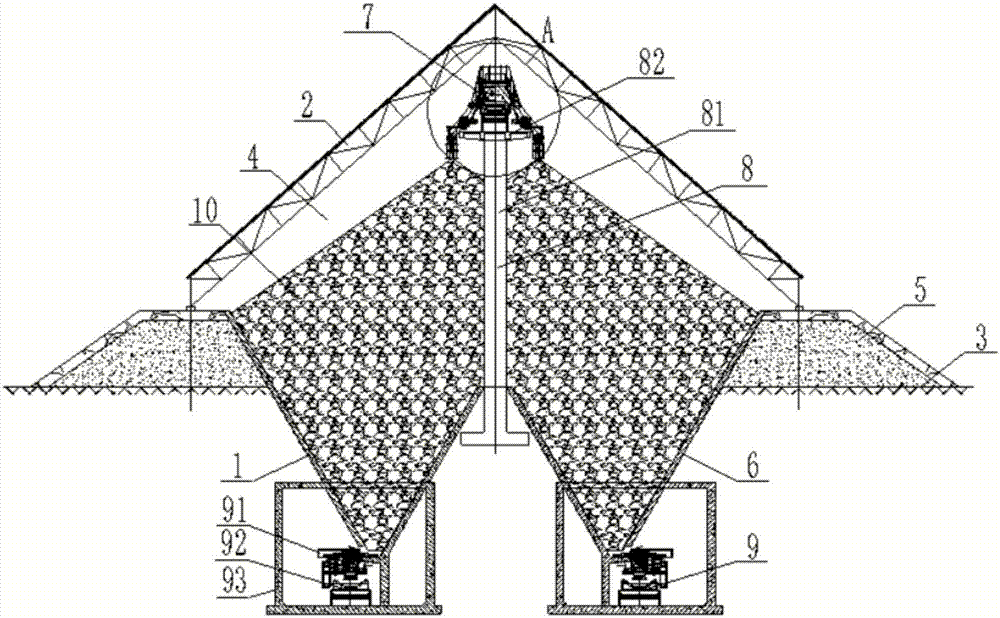

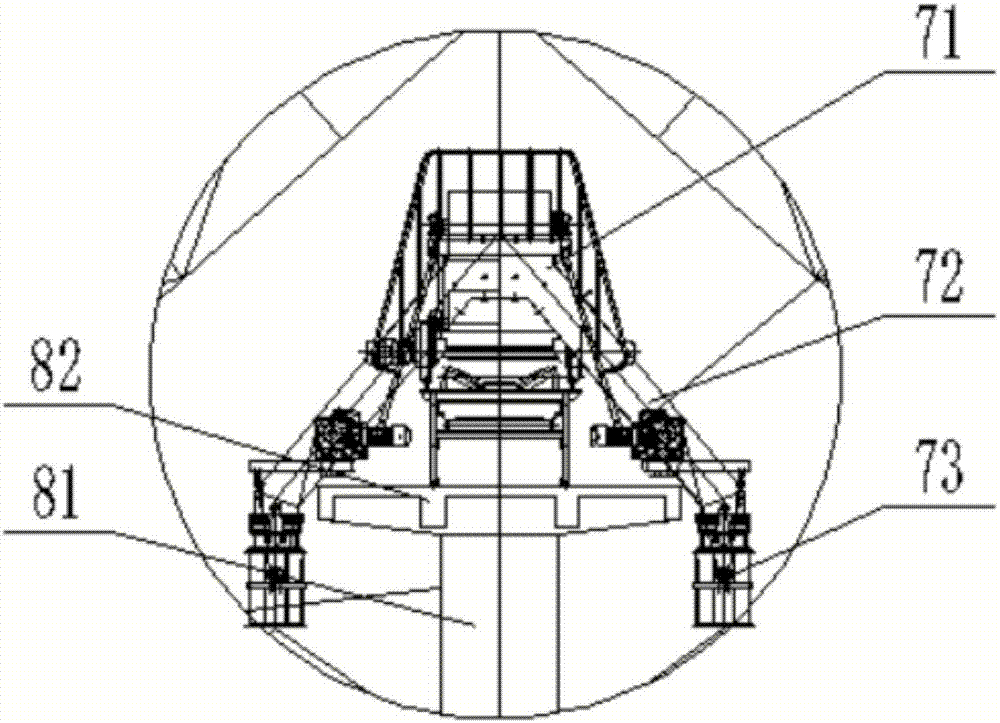

[0028] Such as figure 1 and figure 2 As shown, the antifreeze environment-friendly material yard of the present embodiment includes a thermal insulation placement tank 1 and a material yard cover 2, and the thermal insulation placement tank 1 is arranged below the floor surface 3 for providing bulk material antifreeze heat sources; the material yard cover 2 is provided with Above the heat preservation storage tank 1, a heat preservation chamber 4 for placing bulk materials is formed between the heat preservation storage tank 1 and the material yard cover 2, which prevents the loss of heat and the diffusion of discharge dust, and has a simple structure and high reliability . In the present invention, a thermal insulation storage tank 1 is arranged below the fl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com