Damping ballastless track slab

A ballastless track and track slab technology, which is applied in the field of rail transportation, can solve the problems of compressive and flexural strength reduction, compressive and flexural strength reduction, etc., achieve improved vibration damping performance, obvious vibration damping performance, and benefit the environment Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] In this embodiment, a short sleeper vibration-damping ballastless track slab and a short sleeper ordinary concrete ballastless track slab are made.

[0022] The geometric dimensions of the two track slabs are: length 5500cm, width 2500cm, thickness 20cm, each with 14 short sleepers. See attached figure 1 , attached figure 2 .

[0023] Ordinary concrete track slabs are manufactured according to existing construction techniques and procedures.

[0024] The construction process of vibration-damping ballastless track slabs: vertical mold-binding steel bars-weighing 5% equal volume rubber particles (2-4mm in diameter) of river sand-treating the surface of rubber particles with KH560 coupling agent-drying or drying Rubber granules-mix the dried or dried rubber granules into concrete aggregates and mix them-pour rubber concrete on the track slab-pour sleepers with ordinary concrete-cure-form removal.

Embodiment 2

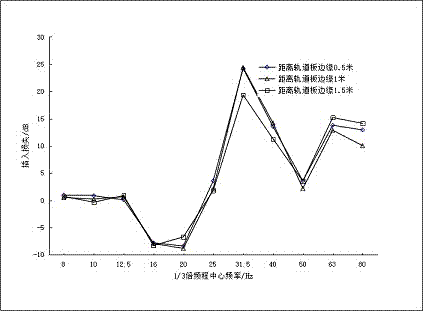

[0026] In this embodiment, the vibration damping performance of the two ballastless track slabs in Embodiment 1 is tested. Including two vibration reduction indicators: Z-direction acceleration vibration level and insertion loss.

[0027] 1. Acceleration vibration level is calculated by the following formula:

[0028]

[0029] in,

[0030] In the formula: a 0 As the reference acceleration, take a 0 for 10 -6 m*s-2;

[0031] Weighted acceleration for frequency domain A, c i is the weighting factor of the i-th 1 / 3 frequency band; a ri is the effective value of the vibration acceleration at the center frequency of the ith 1 / 3 frequency band.

[0032] The test results show the Z-direction acceleration vibration levels of ordinary concrete short-sleeper ballastless track slab and short-sleeper vibration-reducing ballastless track slab at the same position on the track slab, as shown in Table 1 below.

[0033] Table 1. Z-direction acceleration vibration levels of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com