Bamboo-splitting tool capable of removing inner bamboo joints and centering

A technology of centering and breaking bamboo, which is applied in the direction of manufacturing tools, wood processing equipment, and wood splitting devices, etc. It can solve the problems that steel knives cannot be disassembled, the eccentricity of removing bamboo inner nodes, and cannot be replaced, so as to save resources and benefit the environment. , The effect of high bamboo breaking efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

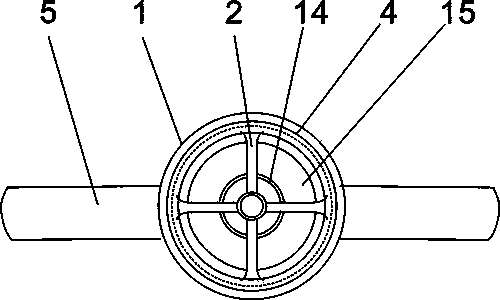

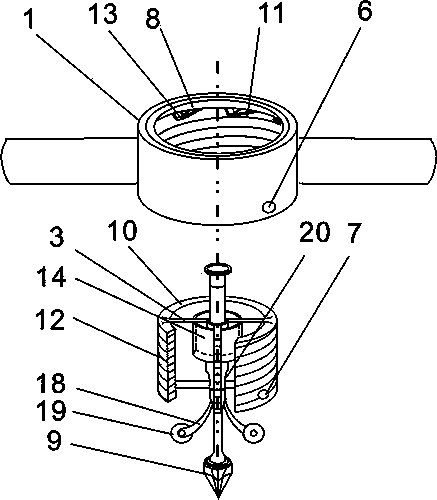

[0015] see Figure 1~Figure 3 , as can be seen from the figure, the broken bamboo cutter that can remove bamboo inner nodes and can be centered includes a cutter body 2 and a cutter holder 1 that places the cutter body 2 inside it. The cutter holder 1 is symmetrically arranged on the steel ring 4 by an annular steel ring 4 The knife handle 5 of the outer wall is composed of; the knife body 2 includes a cutting knife 14, an annular knife ring 10 and a number of steel knives 3 arranged in a scattered structure at equal angles; the cutting knife 14 is fixed on the steel knife 3 Intermittent annular structure coaxial with the knife ring 10, the distance 15 between the cutting knife 14 and the knife ring 10 is slightly greater than the thickness of the bamboo; the starting ends of the steel knife 3 meet at the radial center of the inner diameter of the knife ring 10, and the The terminal is fixed on the inner wall of the knife ring 10; the center of the intersection of the startin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com