Novel block type circle splicing welding machine for stator iron cores

A stator iron core and block type technology is applied in the field of new block type stator iron core round welding machines, which can solve the problems of affecting PCB board welding, difficult results, affecting the down-moving process, etc., to improve work efficiency and automation. The effect of high degree and shortening of production time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

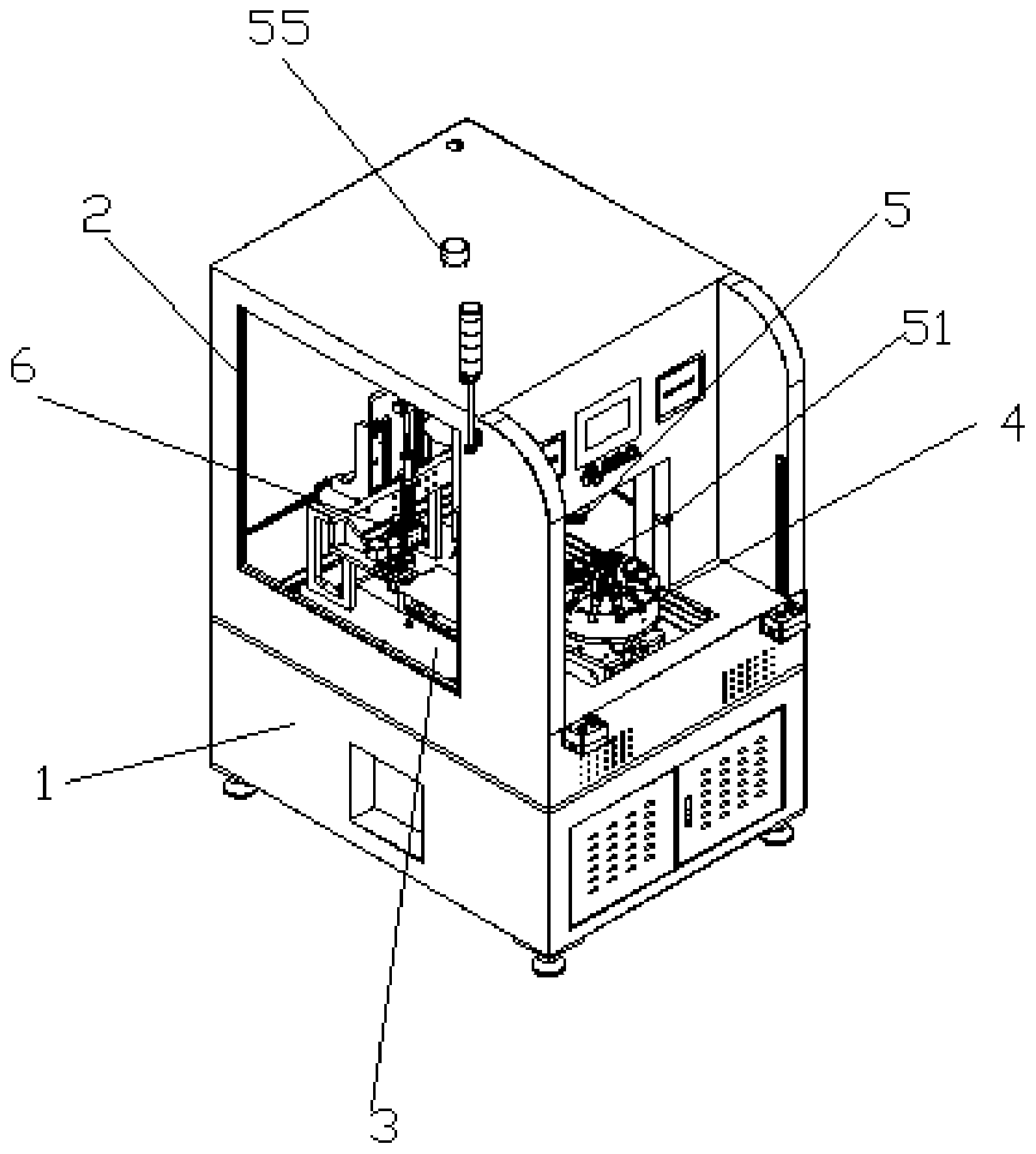

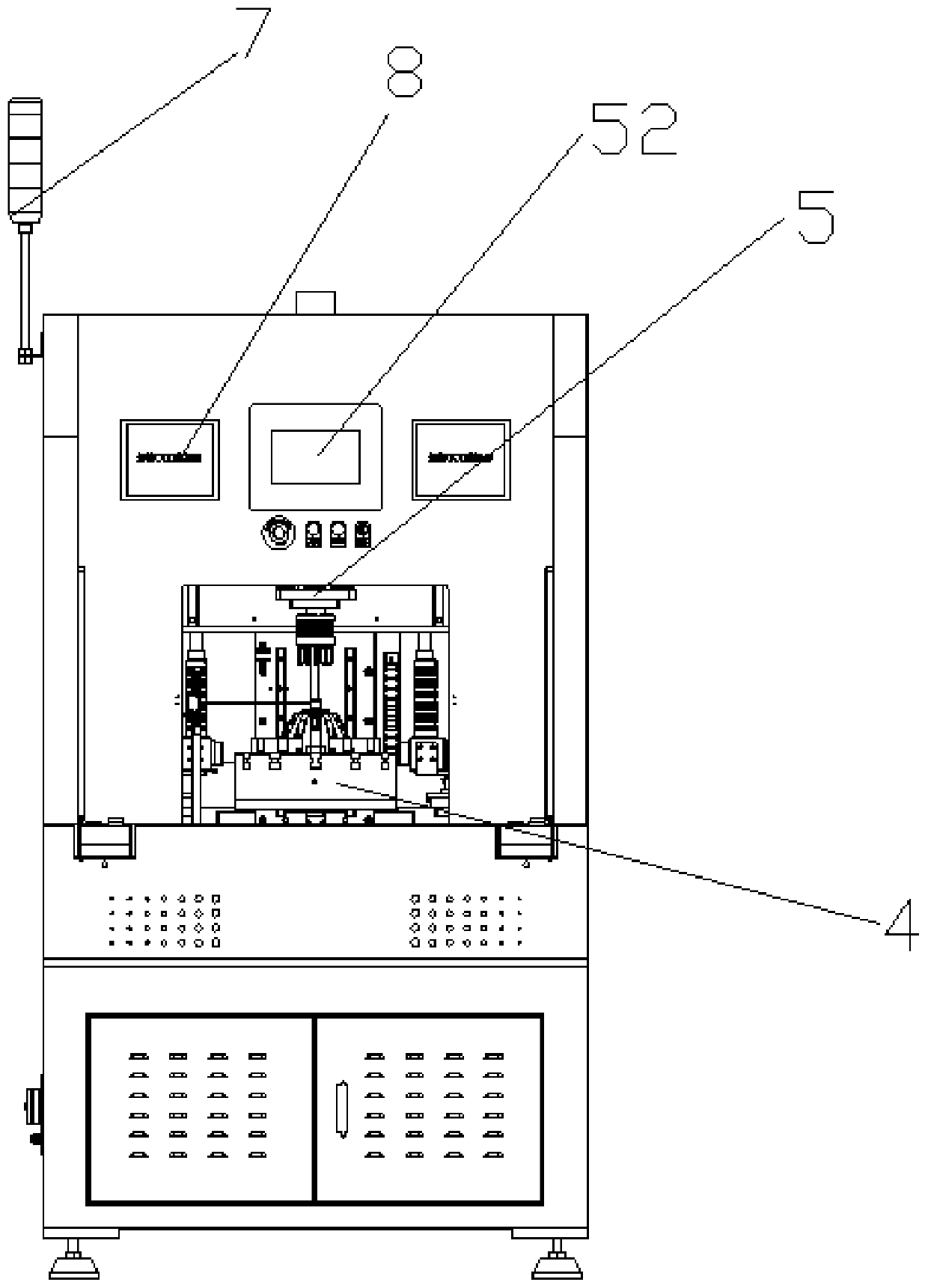

[0047] refer to Figure 1 to Figure 10 A new block-type stator core round welding machine is shown, including a chassis 1, a safety cover 2, a working table 3, a stator tightening mechanism 4, a stator end face shaping mechanism 5, a stator welding mechanism 6, an indicator light 7, The stator core 20, the control panel 52, and the worktable 3 are arranged on the chassis 1, and the chassis 1 and the safety cover 2 are connected as a whole, and the stator tightening mechanism 4, the stator end face shaping mechanism 5, and the stator welding mechanism 6 are all installed on the worktable 3, the control panel 52 controls the work of the stator tightening mechanism 4, the stator end face shaping mechanism 5, and the stator welding mechanism 6, and the two sides of the control panel 52 are provided with welding CCD windows 8, and the stator tightening mechanism 4 is used for multiple The stator core 20 is fixed, the stator end face shaping mechanism 5 is used to press the end face...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com