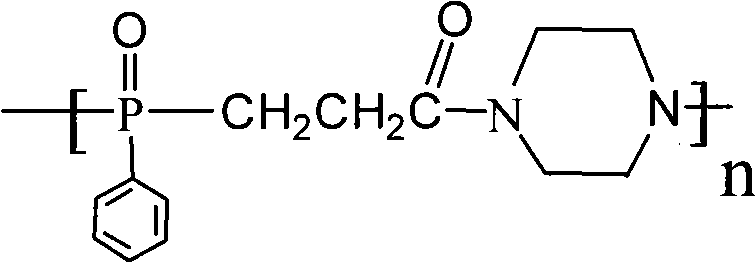

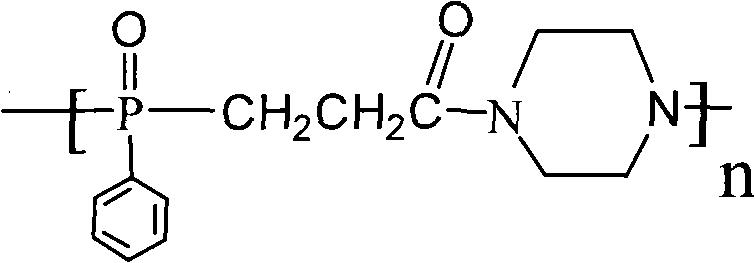

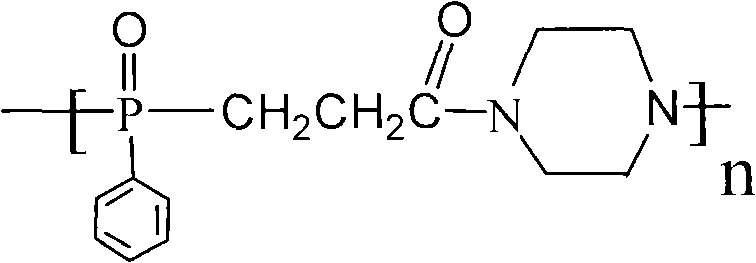

Carboxyethyl phenyl phosphinic acid piperazine polymer and preparation method thereof

A technology based on phosphinic acid and carboxyethylbenzene, which is applied in the field of carboxyethylphenylphosphinic acid piperazine polymer and its preparation, can solve the problems of high cost, complex synthesis process and high price, and achieve cost Inexpensive, good compatibility, good for environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Example 1 In a 250ml three-necked flask equipped with a stirrer and a water separator, pass through nitrogen protection, add 0.1mol carboxyethylphenylphosphinic acid and 0.1mol anhydrous piperazine, add about 40g of water, stir, slowly Raise the temperature until the water evaporates, raise it to 135°C, maintain the temperature for 3 hours, then slowly raise it from 135°C to 160°C for 3 hours, then vacuumize the reaction for 0.5h, cool and solidify, wash the solid with acetone, and then The mixture was filtered with suction, and the filter cake was vacuum-dried to be a white powdery piperazine polymer with carboxyethylphenylphosphinic acid, with a yield of 95%, a melting temperature of 130±5°C, and a decomposition temperature of 200±5°C. ℃.

Embodiment 2

[0036] Example 2 In a 250ml three-necked flask equipped with a stirrer and a water separator, pass through nitrogen protection, add 0.1mol carboxyethylphenylphosphinic acid and 0.095mol anhydrous piperazine, add about 40g of water, stir, slowly Raise the temperature until the water evaporates, raise it to 140°C, maintain the temperature for 2 hours, then slowly raise it from 140°C to 155°C for 2 hours, then vacuumize for 0.5 hours, cool and solidify, dissolve the solid with methanol, add About 8 to 10 times the volume of diethyl ether, milky liquid appears, keep stirring until solid particles appear, then separate liquid and suction filter, and the filter residue is vacuum-dried to become white powder carboxyethylphenylphosphinic acid piperazine The polymer has a yield of 86%, a melting temperature of 130±5°C, and a decomposition temperature of 200±5°C.

Embodiment 3

[0037] Example 3 In a 250ml three-neck flask equipped with a stirrer and a water separator, nitrogen protection was introduced, 0.1mol carboxyethylphenylphosphinic acid and 0.105mol anhydrous piperazine were added, about 40g of water was added, stirred, and slowly Raise the temperature until the water evaporates, raise it to 135°C, maintain the temperature for 4 hours, then slowly raise it from 135°C to 160°C for 4 hours, then vacuumize for 0.5 hours, cool and solidify, wash the solid with acetone, and then The mixture was filtered with suction, and the filter cake was vacuum-dried to be a white powdery piperazine polymer with carboxyethylphenylphosphinic acid, with a yield of 95%, a melting temperature of 130±5°C, and a decomposition temperature of 200±5°C. ℃.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com