Horizontal slurrying device for rare earth mineral

A rare earth mine, horizontal technology, applied in the direction of transportation and packaging, improvement of process efficiency, mixer with rotating container, etc., can solve the problems of many parts, troublesome maintenance and repair, etc., and achieve low manufacturing cost and convenient maintenance and repair , easy to manufacture the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

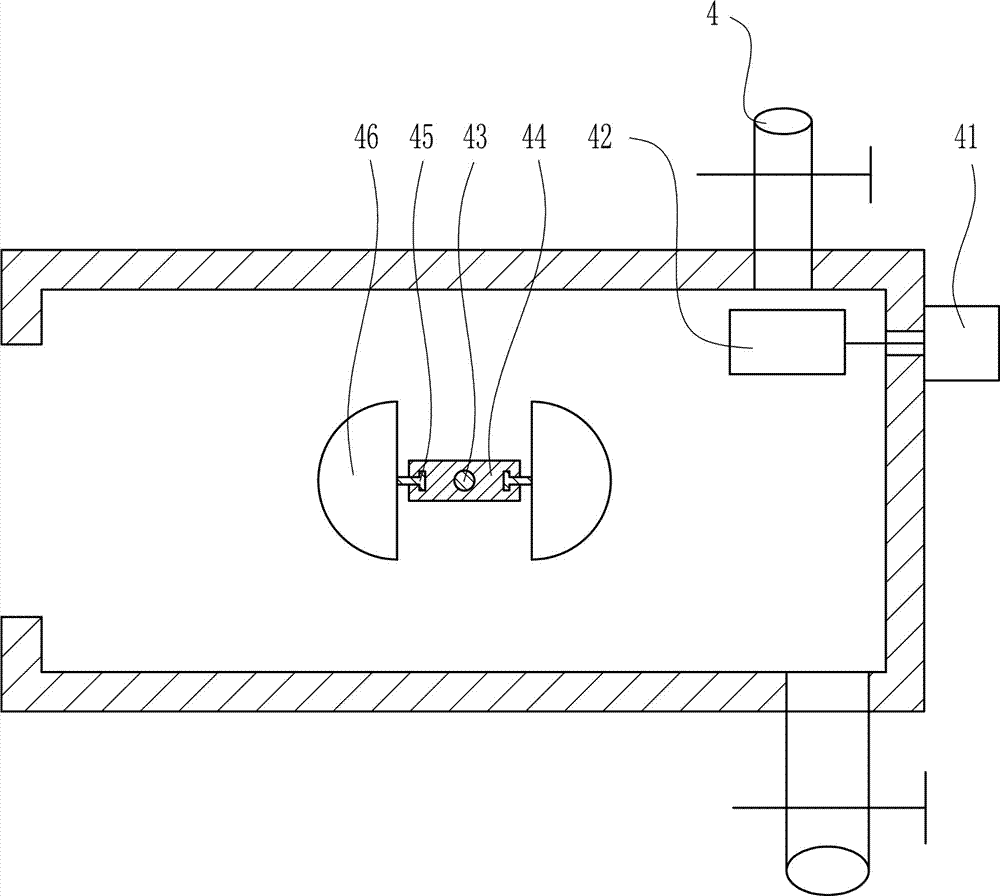

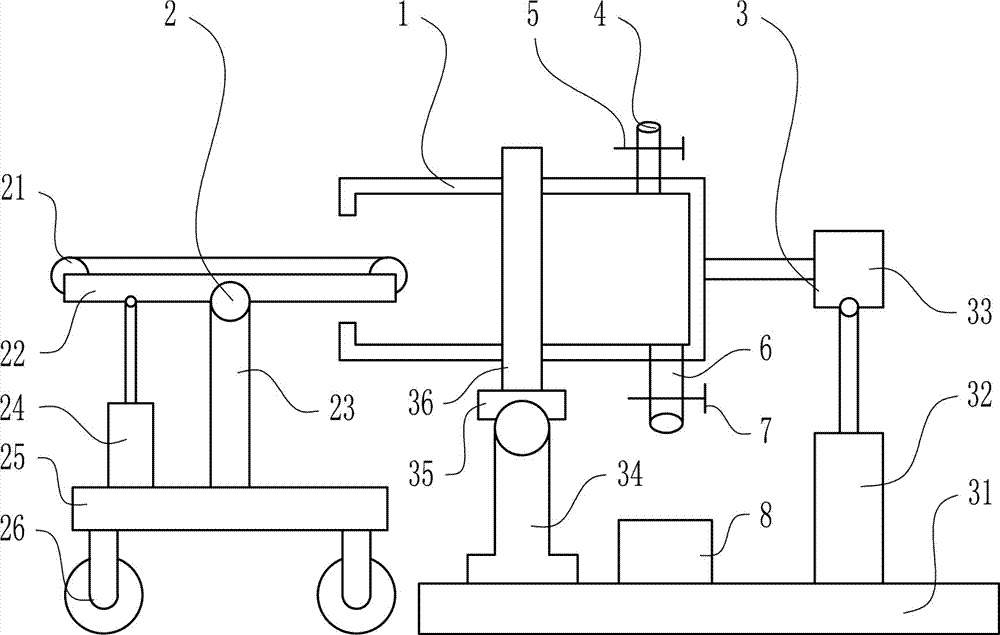

[0027] A horizontal pulping device for rare earth ore, such as Figure 1-3As shown, it includes a mixing drum 1, a conveying device 2, a rotating device 3, an inlet pipe 4, an inlet valve 5, a discharge pipe 6, a discharge valve 7 and a receiving cylinder 8; There is a feed inlet, a conveying device 2 is set on the left side of the mixing drum 1, a rotating device 3 is set on the lower right of the mixing drum 1, a water inlet pipe 4 is welded on the right part of the top of the mixing drum 1, and a water inlet pipe 4 is installed on it. Water inlet valve 5, the right part of mixing drum 1 bottom is welded with discharge pipe 6, and discharge valve 7 is installed on the discharge pipe 6, and material receiving cylinder 8 is arranged on the below of discharge pipe 6.

Embodiment 2

[0029] A horizontal pulping device for rare earth ore, such as Figure 1-3 As shown, it includes a mixing drum 1, a conveying device 2, a rotating device 3, an inlet pipe 4, an inlet valve 5, a discharge pipe 6, a discharge valve 7 and a receiving cylinder 8; There is a feed inlet, a conveying device 2 is set on the left side of the mixing drum 1, a rotating device 3 is set on the lower right of the mixing drum 1, a water inlet pipe 4 is welded on the right part of the top of the mixing drum 1, and a water inlet pipe 4 is installed on it. Water inlet valve 5, the right part of mixing drum 1 bottom is welded with discharge pipe 6, and discharge valve 7 is installed on the discharge pipe 6, and material receiving cylinder 8 is arranged on the below of discharge pipe 6.

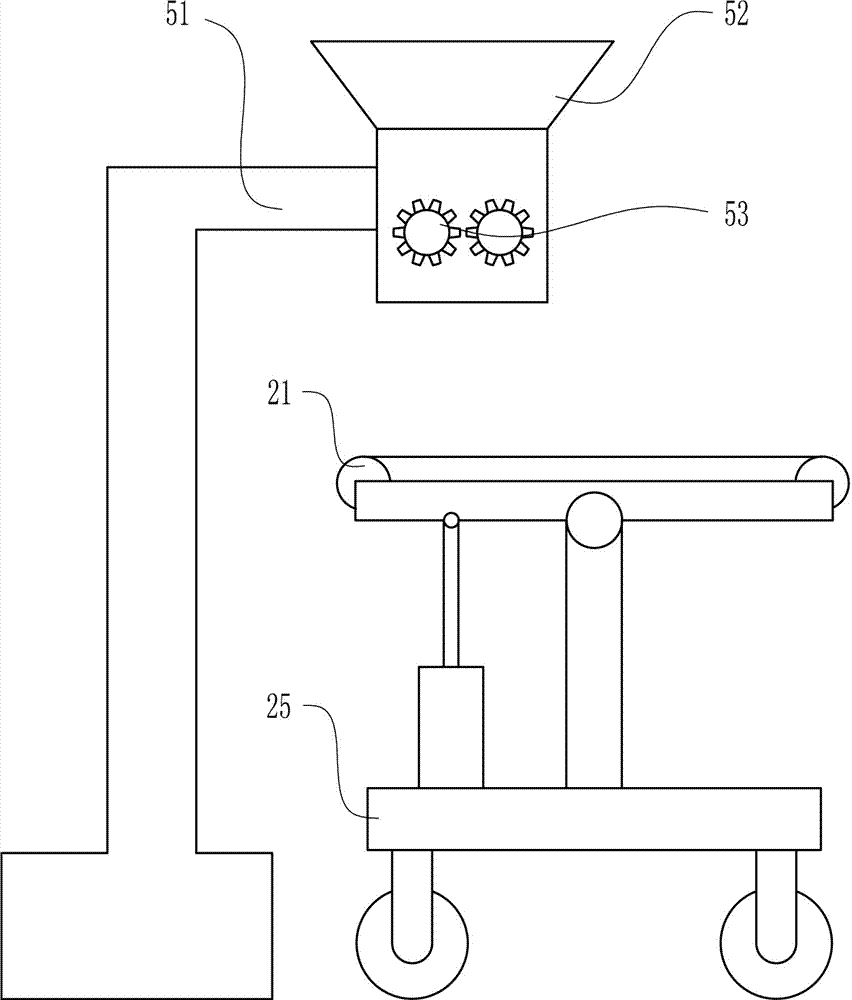

[0030] The conveying device 2 includes a belt conveyor 21, a fixed plate I22, a connecting plate 23, an upper and lower cylinder I24, a supporting plate 25 and a universal wheel 26; In the cylinder 1, a fixed p...

Embodiment 3

[0032] A horizontal pulping device for rare earth ore, such as Figure 1-3 As shown, it includes a mixing drum 1, a conveying device 2, a rotating device 3, an inlet pipe 4, an inlet valve 5, a discharge pipe 6, a discharge valve 7 and a receiving cylinder 8; There is a feed inlet, a conveying device 2 is set on the left side of the mixing drum 1, a rotating device 3 is set on the lower right of the mixing drum 1, a water inlet pipe 4 is welded on the right part of the top of the mixing drum 1, and a water inlet pipe 4 is installed on it. Water inlet valve 5, the right part of mixing drum 1 bottom is welded with discharge pipe 6, and discharge valve 7 is installed on the discharge pipe 6, and material receiving cylinder 8 is arranged on the below of discharge pipe 6.

[0033] The conveying device 2 includes a belt conveyor 21, a fixed plate I22, a connecting plate 23, an upper and lower cylinder I24, a supporting plate 25 and a universal wheel 26; In the cylinder 1, a fixed p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com