Hot melt adhesive used for automotive interior trims and preparation method of hot melt adhesive

A technology for automotive interior parts and hot-melt adhesives, applied in the direction of adhesives, adhesive types, mineral oil hydrocarbon copolymer adhesives, etc., can solve the problems of inability to apply interior adhesives, etc., and achieve long opening time and good toughness , high-strength effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

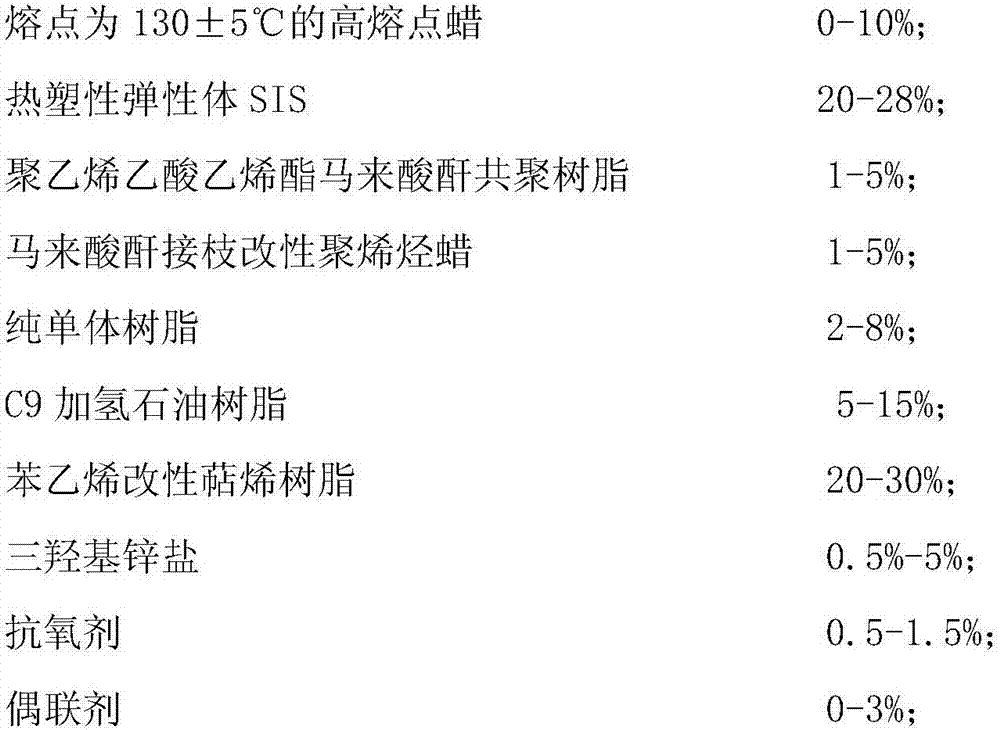

[0033] Refer to Table 1 for specific raw materials.

[0034] Table 1

[0035]

[0036] Wherein, the VA content of the polyethylene vinyl acetate maleic anhydride copolymer resin is 28%, and the polyethylene vinyl acetate maleic anhydride copolymer resin has a melt index of 150 g / 10 min at 190° C.

[0037] The mass of styrene in the thermoplastic elastomer SIS accounts for 25-35% of the mass of the thermoplastic elastomer SIS, and the melt index of the thermoplastic elastomer SIS at 190°C is 5-15g / 10min.

[0038] The softening point of C9 hydrogenated petroleum resin is ≥95°C, and the acid value is less than 5mgKOH / g.

[0039] The softening point of the styrene-modified terpene resin is ≥105°C, and the acid value is less than 5mgKOH / g.

[0040] Preferably, the pure monomer resin in this embodiment is a rosin-modified resin with a softening point ≥ 80°C.

[0041] As preferably, the antioxidant in this embodiment is phenyl-β-naphthylamine, 2,6-di-tert-butyl-p-cresol or phen...

Embodiment 2

[0051] Refer to Table 2 for specific raw materials.

[0052] Table 2

[0053]

[0054] Wherein, the VA content of the polyethylene vinyl acetate maleic anhydride copolymer resin is 28%, and the polyethylene vinyl acetate maleic anhydride copolymer resin has a melt index of 150 g / 10 min at 190° C.

[0055] The mass of styrene in the thermoplastic elastomer SIS accounts for 25-35% of the mass of the thermoplastic elastomer SIS, and the melt index of the thermoplastic elastomer SIS at 190°C is 5-15g / 10min.

[0056] The softening point of C9 hydrogenated petroleum resin is ≥95°C, and the acid value is less than 5mgKOH / g.

[0057] The softening point of the styrene-modified terpene resin is ≥105°C, and the acid value is less than 5mgKOH / g.

[0058] Preferably, the pure monomer resin in this embodiment is a rosin-modified resin with a softening point ≥ 80°C.

[0059] As preferably, the antioxidant in this embodiment is phenyl-β-naphthylamine, 2,6-di-tert-butyl-p-cresol or phen...

Embodiment 3

[0069] Refer to Table 3 for specific raw materials.

[0070] table 3

[0071]

[0072]

[0073] Wherein, the VA content of the polyethylene vinyl acetate maleic anhydride copolymer resin is 28%, and the polyethylene vinyl acetate maleic anhydride copolymer resin has a melt index of 150 g / 10 min at 190° C.

[0074] The mass of styrene in the thermoplastic elastomer SIS accounts for 25-35% of the mass of the thermoplastic elastomer SIS, and the melt index of the thermoplastic elastomer SIS at 190°C is 5-15g / 10min.

[0075] The softening point of C9 hydrogenated petroleum resin is ≥95°C, and the acid value is less than 5mgKOH / g.

[0076] The softening point of the styrene-modified terpene resin is ≥105°C, and the acid value is less than 5mgKOH / g.

[0077] Preferably, the pure monomer resin in this embodiment is a rosin-modified resin with a softening point ≥ 80°C.

[0078] As preferably, the antioxidant in this embodiment is phenyl-β-naphthylamine, 2,6-di-tert-butyl-p-cr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com