Anti-corrosion inclusion bored concrete pile used for saline soil foundation and construction method thereof

A technology of concrete piles and construction methods, which is applied in the direction of foundation structure engineering, sheet pile walls, buildings, etc., can solve the problems of reducing concrete strength and high cost of anti-corrosion treatment, and achieve the effects of reducing project cost, saving materials, and increasing frictional resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] Examples see Figure 1 ~ Figure 2 As shown, a kind of anti-corrosion encased concrete cast-in-situ pile applied on saline soil foundation comprises a concrete pile body 14, a steel cage 3 is arranged in the concrete pile body 14, and a flexible rubber cage is wrapped on the bottom and the periphery of the concrete pile body 14 Water-proof anti-corrosion protection cylinder 2.

[0051] The water-proof and anti-corrosion protection tube 2 is formed by hot pressing or welding n-1 layers of geomembrane sandwiched by n layers of polyethylene geotextile bags, n≥2. The geomembrane is polypropylene geomembrane or composite geomembrane. Polyethylene geotextile bags can be filament woven high-strength geotextile bags, woven geotechnical anti-seepage bags, woven geotechnical composite bags or woven geotextiles. It can be two cloth clips and one film.

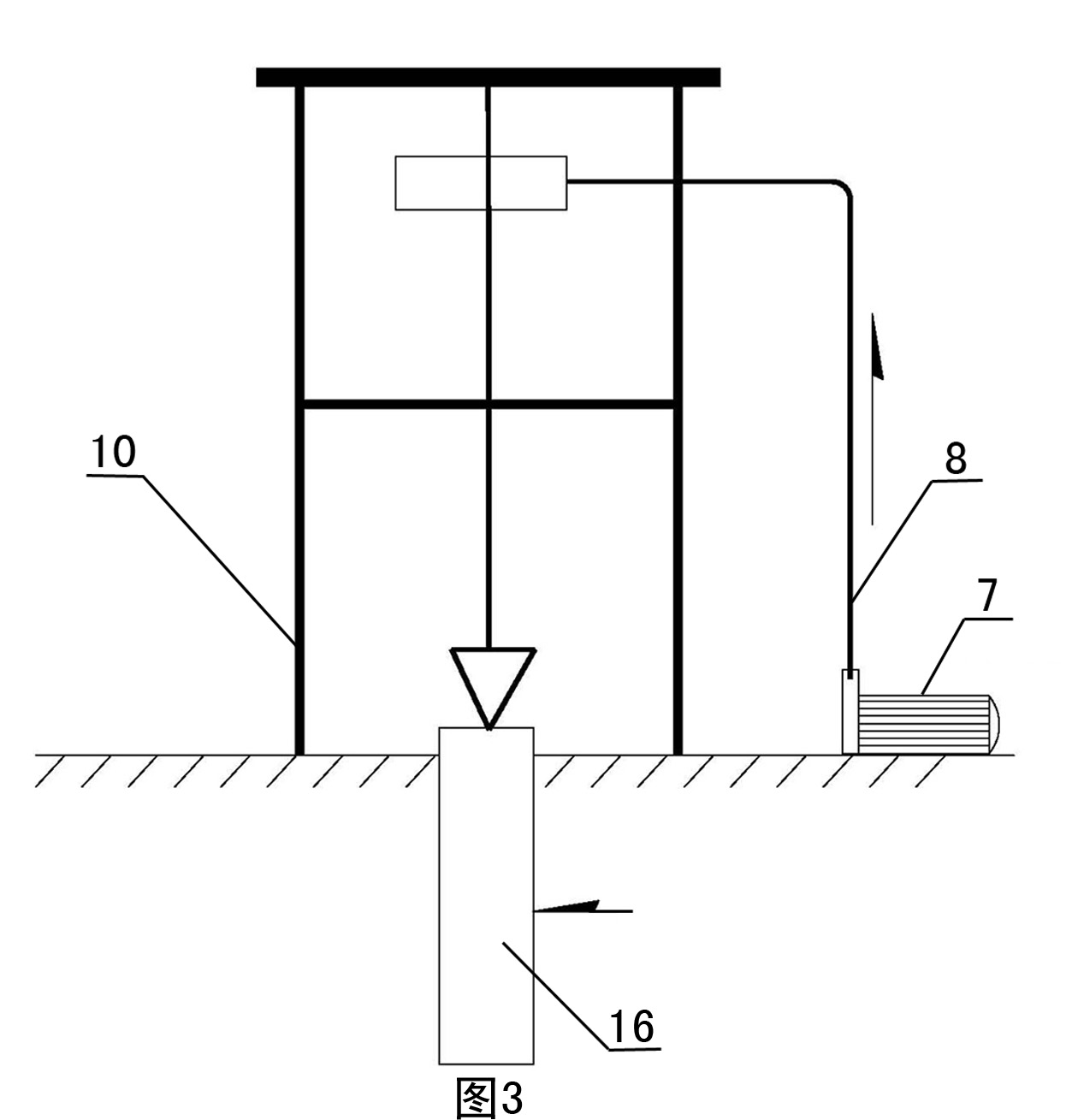

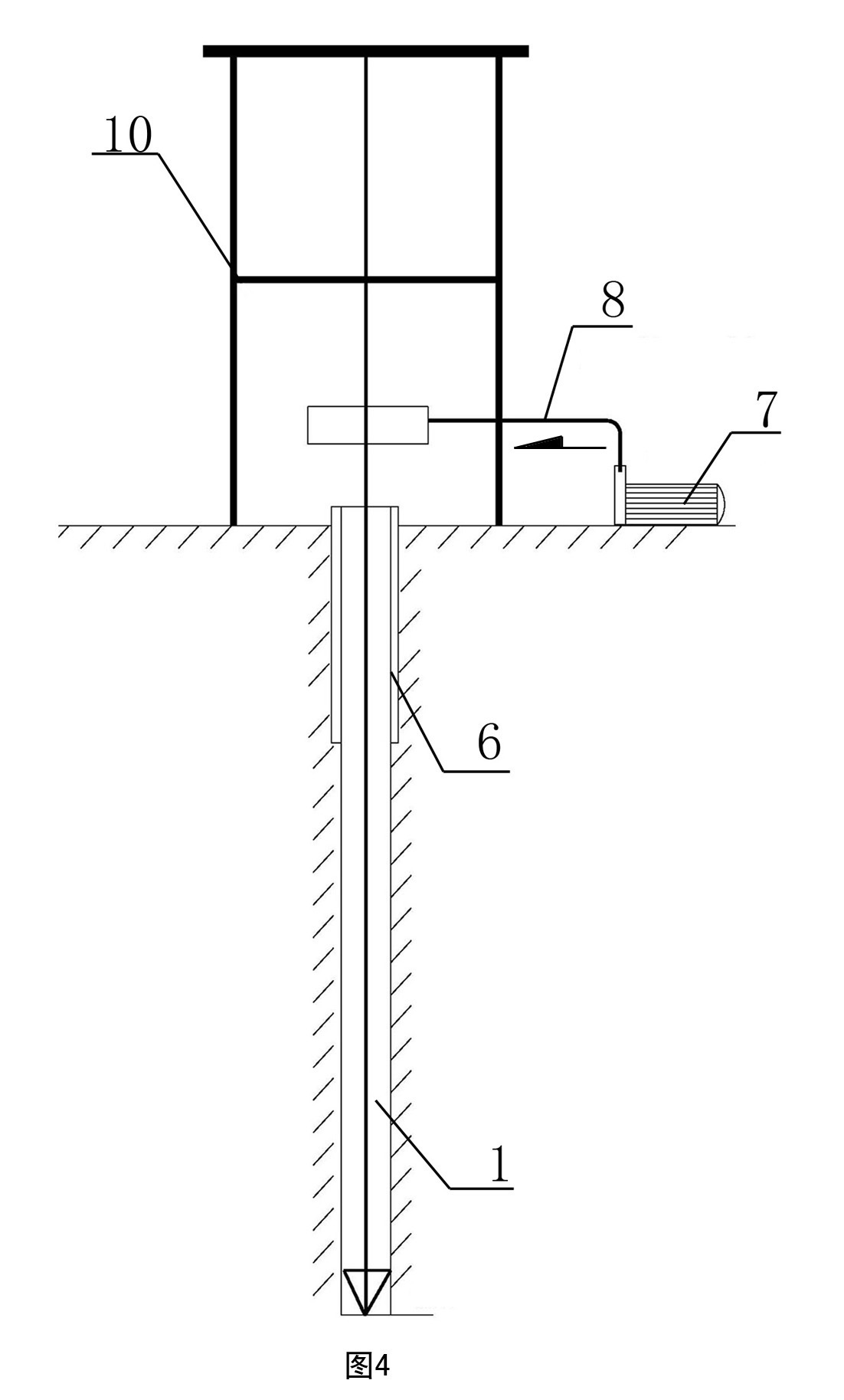

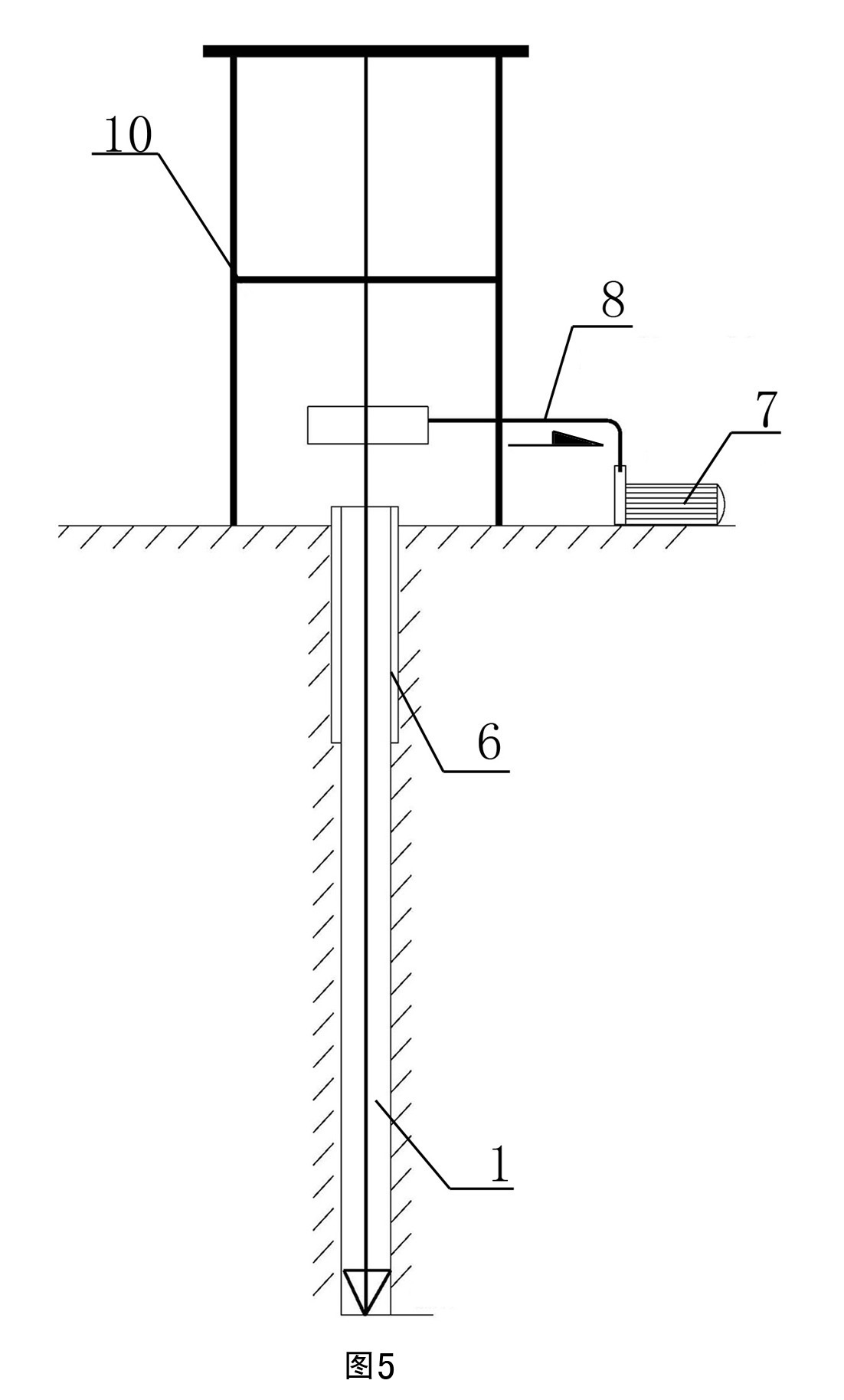

[0052] see Figure 3 ~ Figure 13 As shown, the construction steps of the above-mentioned anti-corrosion encased concrete cast-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com