High-temperature activated potash feldspar, and preparation method thereof

A technology for activating potassium and potassium feldspar, which is applied to chemical instruments and methods, potash fertilizers, organic fertilizers, etc. It can solve the problems of uncontrollable reactions, cumbersome production process, and high calcination temperature, and achieve the improvement of soil pollution status. The effect of low temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

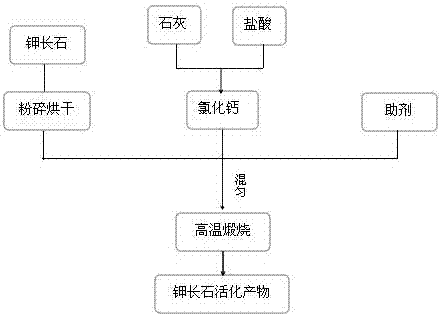

Image

Examples

Embodiment 1

[0022] Mix quicklime and hydrochloric acid at a molar ratio of 2:1, and stir evenly. After the reaction is complete, mix with crushed and sieved potassium feldspar and activated carbon at a mass ratio of 0.8:1:0.2 to obtain a mixed material, add water to mix, and stir evenly , and then put the mixed material into the wheel kiln, calcined at 900 ° C for 30 minutes, let in air to cool to room temperature, cool, take out, crush, and pass through 80 mesh sieve to obtain the activated product of potassium feldspar.

[0023] The potassium feldspar activation product obtained in this example is tested according to the agricultural testing standards NY / T2272-2012, NY / T1973-2010 and NY / T2540-2014, and the results are as follows:

[0024] name

Embodiment 2

[0026] Mix slaked lime and hydrochloric acid at a molar ratio of 2:1, stir evenly, and mix with crushed and sieved potassium feldspar, gypsum powder, and activated carbon at a mass ratio of 0.9:1:0.15:0.1 to obtain the mixed material , add water to mix, stir evenly, and then put the mixed material into the vertical kiln, calcinate at 950 ℃ for 40 min, cool, take out, crush, and pass through a 100-mesh sieve to obtain the activated product of potassium feldspar.

[0027] The potassium feldspar activation product obtained in this example is tested according to the agricultural testing standards NY / T2272-2012, NY / T1973-2010 and NY / T2540-2014, and the results are as follows:

[0028] name

Embodiment 3

[0030] Mix limestone and hydrochloric acid at a molar ratio of 2:1, stir evenly, and mix with crushed and sieved potassium feldspar and calcium sulfate at a mass ratio of 1:1:0.2 after the reaction is sufficient to obtain a mixed material, add water and mix, Stir evenly, then put the mixed material into the rotary kiln, calcinate at 950°C for 30 minutes, cool, take out, crush, and pass through an 80-mesh sieve to obtain the activated product of potassium feldspar.

[0031] The potassium feldspar activation product obtained in this example is tested according to the agricultural testing standards NY / T2272-2012, NY / T1973-2010 and NY / T2540-2014, and the results are as follows:

[0032] name

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com