Thorn-like silica ball and preparation method thereof

A technology of silica spheres and silica, which is applied in the direction of silica, silica, nanotechnology, etc., can solve the problems that cannot fully meet the application of silica spheres, and the shape is not much, and achieve high pore volume and preparation methods The effect of simplicity and high specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

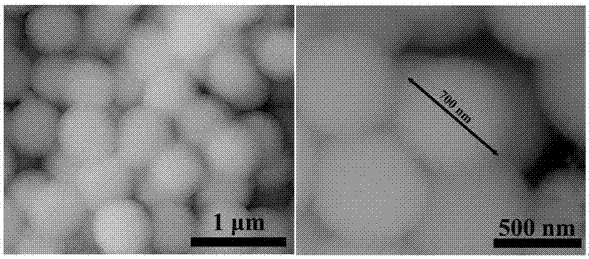

Embodiment 1

[0041] Weigh 4 g of cetylpyridine bromide and 2 g of urea, mix and dissolve in 100 mL of water to obtain solution A, and take 10 g of tetramethyl orthosilicate, dissolve in 100 mL of cyclohexane and n-pentanol 5 Solution B was obtained from a mixed solution of mL, and while stirring at 500rpm, add solution A dropwise to solution B at a rate of 2-20 mL / min, continue stirring at this stirring speed for 1 h at room temperature, and transfer to the reaction After the still, heat it in a conventional oven at 120°C for 6 h, after cooling, filter, wash, dry, transfer to a muffle furnace and bake at 500°C to obtain highly uniform thorn-like silica balls with a size of 700nm about. SEM image see figure 1 and X - ray diffraction pattern see Figure 15 .

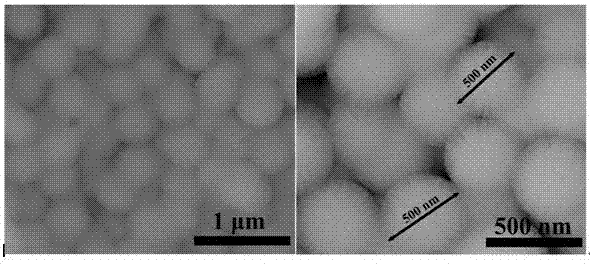

Embodiment 2

[0043]Weigh 4 g of cetylpyridine bromide and 2 g of urea, mix and dissolve in 100 mL of water to obtain solution A, and take 10 g of tetramethyl orthosilicate, dissolve in 100 mL of cyclohexane and n-pentanol 5 The solution B was obtained from the mixed solution of mL. While stirring at 1500rpm, the solution A was added dropwise to the solution B at a rate of 2-20 mL / min. Stirring was continued at room temperature for 1 h at the stirring rate, and transferred to the reaction After the kettle, heat it in a conventional oven at 120°C for 6 hours. After cooling, filter, wash, dry, transfer to a muffle furnace and bake at 500°C to obtain highly uniform thorn-like silica balls with a size of 500nm. about. SEM image see figure 2 .

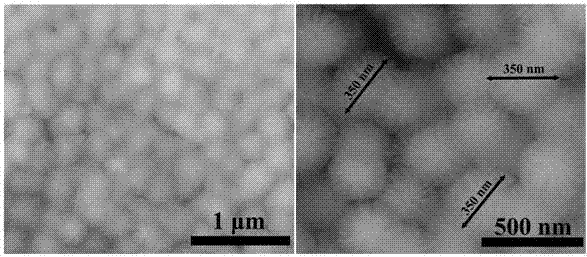

Embodiment 3

[0045] Weigh 4 g of cetylpyridine bromide and 2 g of urea, mix and dissolve in 100 mL of water to obtain solution A, and take 10 g of tetramethyl orthosilicate, dissolve in 100 mL of cyclohexane and n-pentanol 5 mL of the mixed solution to obtain solution B, while stirring at 2000rpm, add solution A dropwise to solution B at a rate of 2-20 mL / min, continue stirring for 1 h at room temperature at this stirring speed, and transfer to the reaction After the kettle, heat it in a conventional oven at 120°C for 6 h, after cooling, filter, wash, dry, transfer to a muffle furnace and bake at 500°C to obtain highly uniform thorn-like silica balls with a size of 350nm about. SEM image see image 3 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com