Intelligentized multi-loop thermal management system of electric automobile

A thermal management system and electric vehicle technology, applied in the field of intelligent multi-circuit electric vehicle thermal management system, can solve the problems of reducing heat dissipation and heating, short vehicle cruising range, and fewer control circuits, so as to maintain heat balance and ensure efficient operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

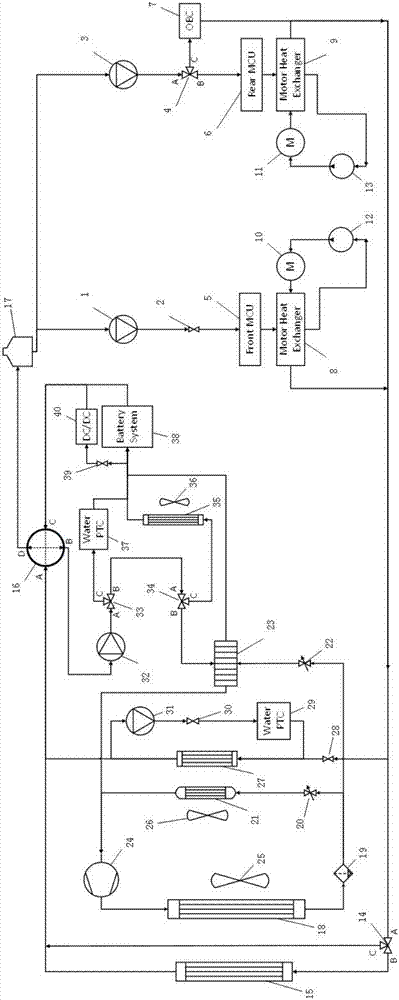

[0066] refer to figure 1 , an intelligent multi-circuit electric vehicle thermal management system, including a power battery pack 38, a drive motor, a motor controller, an on-board charger 7, a DC / DC converter 40, a battery radiator 35, a battery cooler 23, and a motor heat dissipation 15, electric water pump, electric oil pump, expansion tank 17, PTC heater, heat exchanger, electric compressor 24, condenser 18, evaporator 21, liquid storage drying pot 19, warm air core 27, four-way valve 16 , three-way valve, straight-through valve and electronic expansion valve.

[0067] In the present embodiment, drive motor is provided with 2, comprises first drive motor 10, second drive motor 11; Motor controller is provided with 2, comprises first motor controller 5, second motor controller 6; Electric water pump There are 4 electric water pumps, including the first electric water pump 1, the second electric water pump 3, the third electric water pump 31, and the fourth electric water ...

Embodiment 2

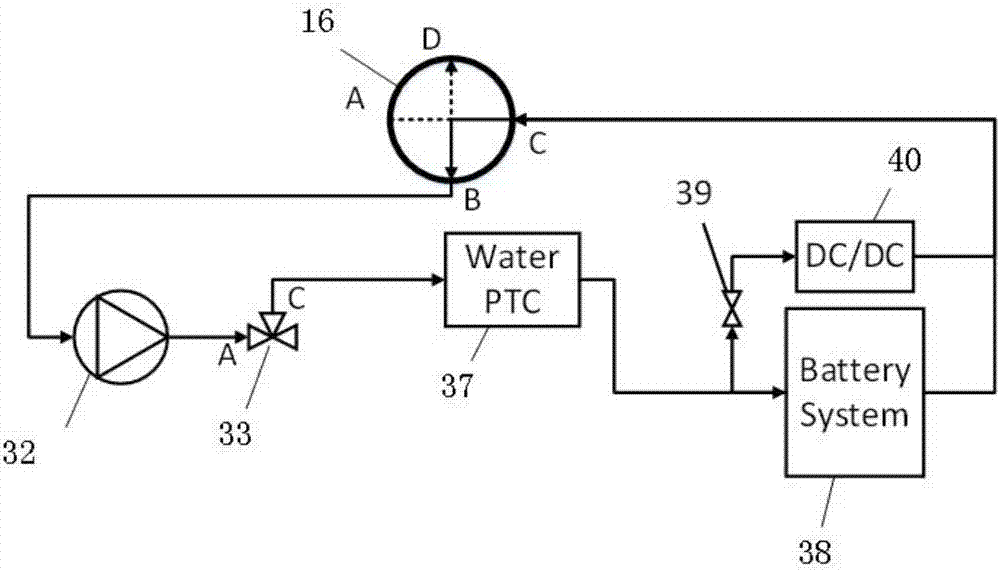

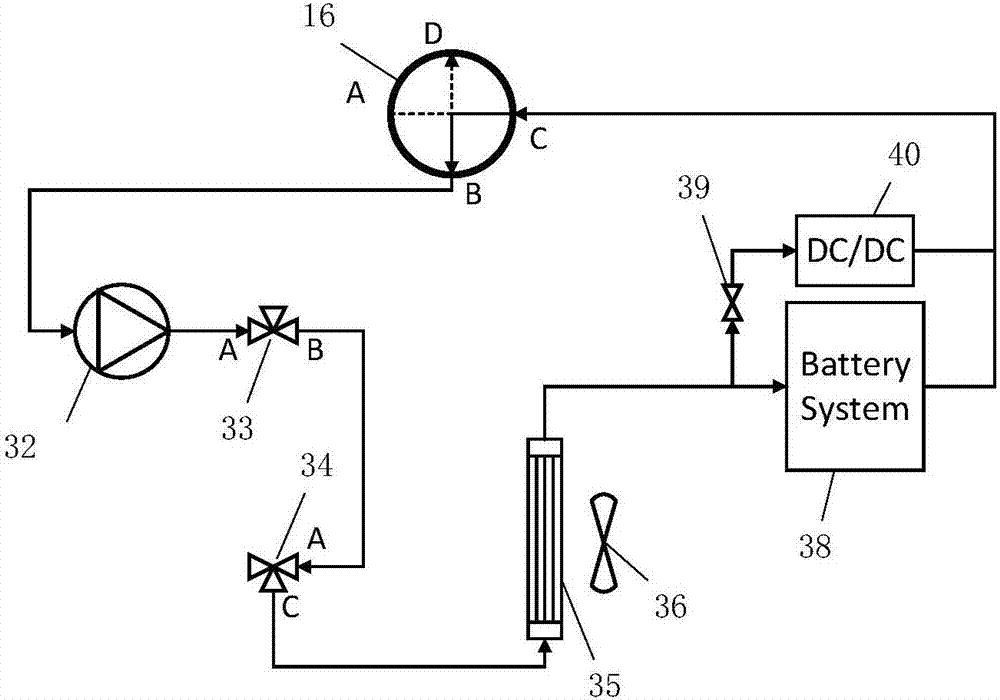

[0073]When the electric vehicle is running, the power battery pack 38 needs to be kept in a suitable temperature range. For lithium-ion batteries, it is generally considered that the temperature is in a reasonable range in the range of 0-40°C, neither too hot nor too cold. When the temperature of the power battery pack 38 is in a reasonable range, but the temperature difference between the individual cells is too large, beyond the reasonable range (usually it is considered that the temperature difference between the single cells is less than 5°C is a reasonable range), the power battery pack needs to be adjusted. 38 for temperature equalization.

[0074] refer to figure 2 , the coolant is driven by the fourth electric water pump 32, first flows into the inlet A of the third three-way valve 33 and then flows out from the outlet C, and then flows through the second PTC heater 37 (at this time, the second PTC heater 37 is not working), Then flow into the internal cooling pipel...

Embodiment 3

[0079] refer to Figure 6 and Figure 7 , the first electric oil pump 12, the first drive motor 10, and the first heat exchanger 8 are connected in series to form a first drive motor oil cooling circuit; the second electric oil pump 13, the second drive motor 11, and the second heat exchanger 9 The connection forms the second drive motor oil cooling circuit. The drive motor oil cooling circuit has more advantages than the traditional motor liquid cooling circuit, because the insulating heat transfer oil can enter the drive motor to directly cool the motor rotor, and the cooling effect is better.

[0080] refer to Figure 8 , consisting of the first electric water pump 1, the first through valve 2, the first motor controller 5, the first heat exchanger 8, the second electric water pump 3, the first three-way valve 4, the second motor controller 6, the first Two heat exchangers 9, an on-board charger 7, a second three-way valve 14, a motor radiator 15, a first electric fan 25...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com