Anti-blocking and scouring-resistant bidirectional seal adjusting valve

A two-way sealing and regulating valve technology, which is applied to valve devices, cocks including cut-off devices, engine components, etc. problems, to achieve the effect of ensuring long-term safe and reliable application and efficient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with specific embodiments, but the protection scope of the present invention is not limited thereto.

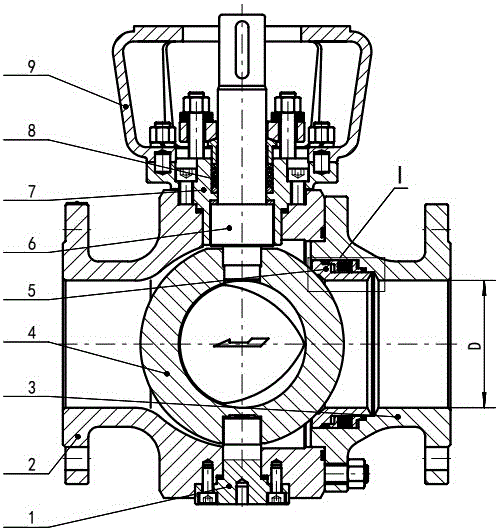

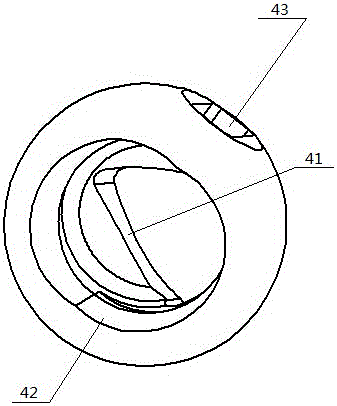

[0023] Such as Figure 1-3 As shown, the anti-clogging and erosion resistant bidirectional sealing regulating valve of the present invention includes a valve body 2 and a valve cover 3. The valve body 2 is provided with a valve seat assembly 5, the valve seat assembly 5 is installed with a valve ball 4, and the valve ball 4 is above A valve stem 6 and a lower shaft 1 are respectively provided below and below. A gland 7 is arranged on the outside of the valve stem 6 and a bracket 9 is arranged on the outside of the gland 7. A packing 8 is arranged between the gland 7 and the valve stem 6.

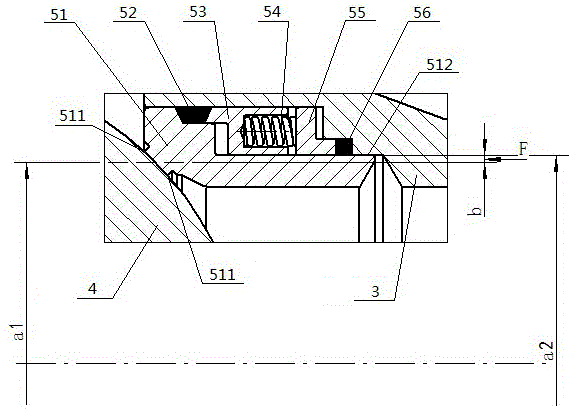

[0024] The valve seat assembly 5 in the present invention is a single non-invasive, two-way sealing structure. The main sealing direction of the valve seat assembly 5 is that the valve seat 51 flows to the valve ball 4 e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com