Preparation method of nanometer Fe3O4 (ferroferric oxide)/etherified bacterial cellulose composite heavy metal adsorbing material

A technology of bacterial cellulose and adsorption materials, applied in chemical instruments and methods, alkali metal compounds, adsorption of water/sewage treatment, etc., to achieve high-efficiency adsorption, simple operation, and convenient separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

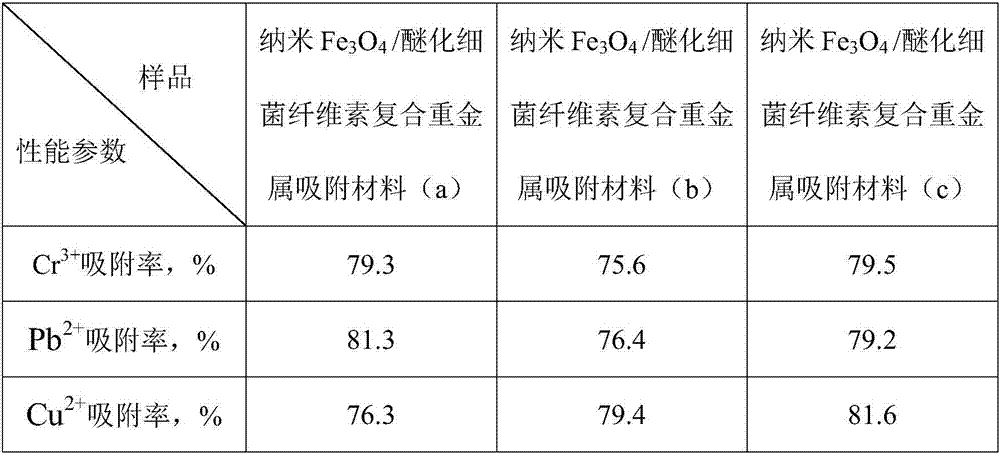

Examples

Embodiment 1

[0020] 1) Under sterile conditions, inoculate Acetobacter xylinum (ATCC 23767) into 70 mL of liquid fermentation medium (10 g / L sodium carboxymethylcellulose, 30 g / L glucose, 13 g / L yeast extract, 15 g / L peptone , 2.4g / L citric acid, 3.4g / L magnesium sulfate, 3.2g / L Na 2 HPO 4 , 2.4g / L KH 2 PO 4 , pH 7, sterilized by high-temperature and high-pressure steam at 110°C for 30 minutes), cultured on a constant temperature shaker with a culture temperature of 28°C and a rotation speed of 160r / min for 18h, and then transferred to a constant temperature biochemical incubator with a culture temperature of 31°C for static culture for 7 days , removing the fermentation broth to obtain unpurified etherified bacterial cellulose membrane;

[0021] 2) Wash the unpurified etherified bacterial cellulose membrane material obtained in step 1) with deionized water, remove the residual culture medium and brown colloidal substance on the surface, and place it in 50 mL of NaOH solution with a con...

Embodiment 2

[0024] 1) Under sterile conditions, inoculate Acetobacter xylinum (GDMCC 1.423) into 70 mL of liquid fermentation medium (20 g / L sodium carboxymethylcellulose, 28 g / L glucose, 15 g / L yeast extract, 13 g / L peptone , 3g / L citric acid, 3.0g / L magnesium sulfate, 3.4g / L Na 2 HPO 4 , 2.8g / L KH 2 PO 4 , pH 6, sterilized by high-temperature and high-pressure steam at 110°C for 30 minutes), cultured on a constant temperature shaker with a culture temperature of 31°C and a rotation speed of 140r / min for 12h, and then transferred to a constant temperature biochemical incubator with a culture temperature of 29°C for static culture for 5 days , removing the fermentation broth to obtain unpurified etherified bacterial cellulose membrane;

[0025] 2) Wash the unpurified etherified bacterial cellulose membrane material obtained in step 1) with deionized water, remove the medium and brown colloidal substances remaining on the surface, and place it in 100 mL of NaOH solution with a concentra...

Embodiment 3

[0028] 1) Under sterile conditions, inoculate Acetobacter xylinum (ATCC 23767) into 70 mL of liquid fermentation medium (30 g / L sodium carboxymethylcellulose, 25 g / L glucose, 10 g / L yeast extract, 10 g / L peptone , 2.7g / L citric acid, 2.6g / L magnesium sulfate, 3.0g / L Na 2 HPO 4 , 2.6g / L KH 2 PO 4 , pH 8, sterilized by high-temperature and high-pressure steam at 110°C for 30 minutes), cultured on a constant temperature shaker with a culture temperature of 30°C and a rotation speed of 150r / min for 24 hours, and then transferred to a constant temperature biochemical incubator with a culture temperature of 28°C for static culture for 6 days , removing the fermentation broth to obtain unpurified etherified bacterial cellulose membrane;

[0029] 2) Wash the unpurified etherified bacterial cellulose membrane material obtained in step 1) with deionized water, remove the medium and brown colloidal substances remaining on the surface, and place it in 75 mL of NaOH solution with a conc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com