Preparation method of molybdenum disulfide/copper sulfide/cuprous oxide nano-composite material

A nano-composite material, cuprous oxide technology, applied in the direction of copper oxide/copper hydroxide, molybdenum sulfide, chemical instruments and methods, to achieve the effect of promoting separation, high sample uniformity, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

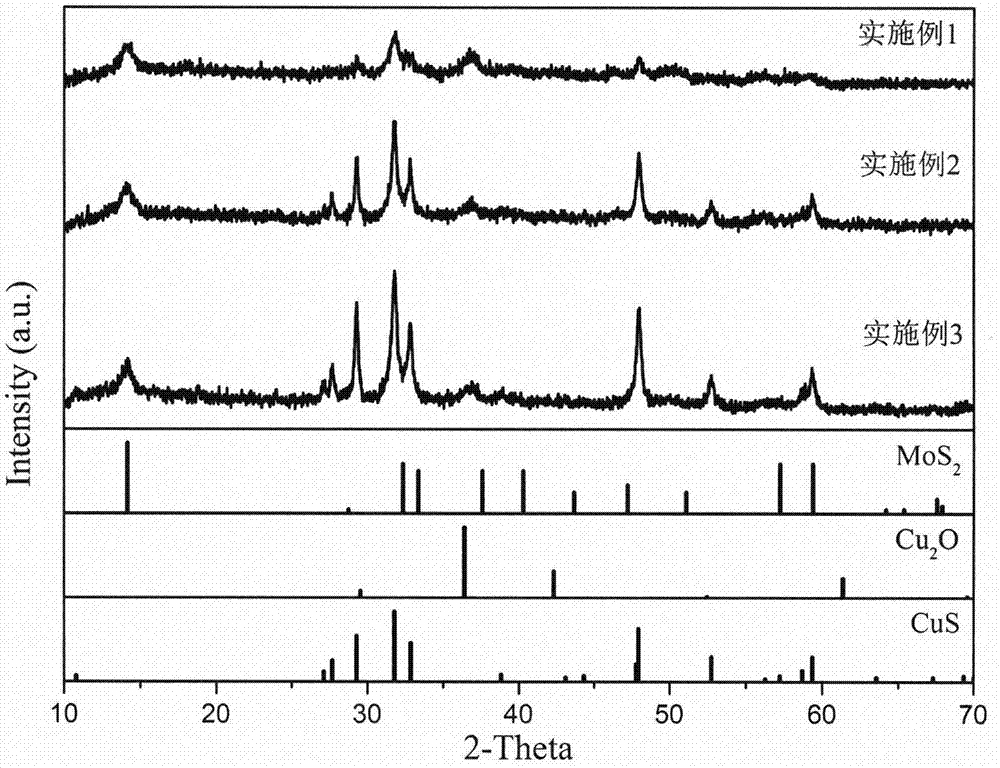

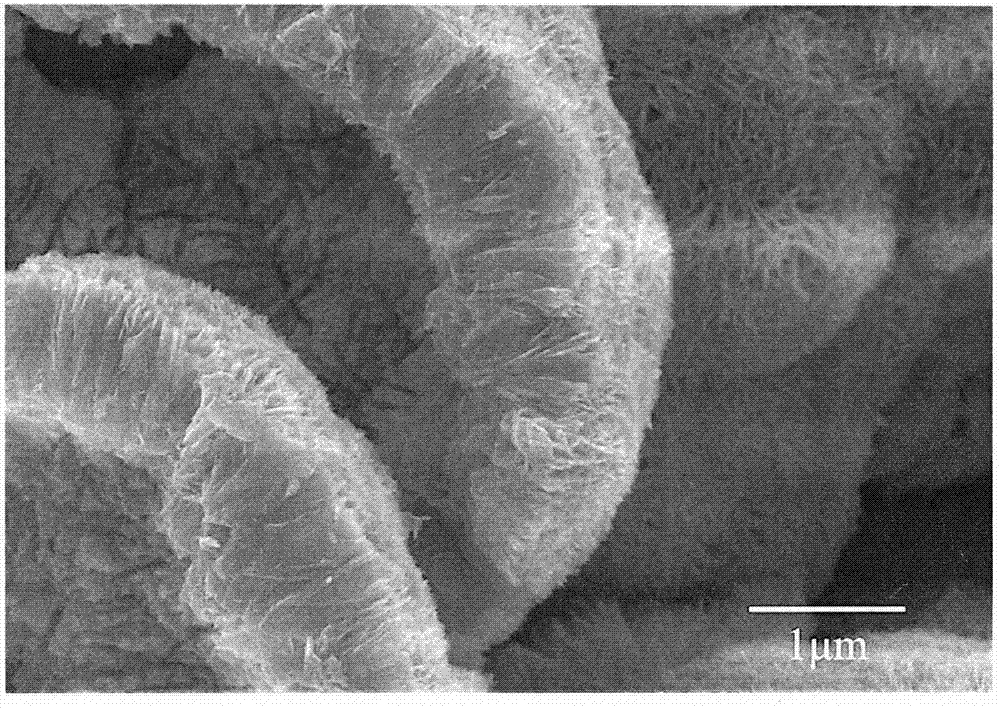

[0034] Add 0.175g copper oxide to deionized water, stir magnetically to obtain the mixture, then add 0.6g sodium molybdate dihydrate, continue magnetic stirring, then add 2.4g thiourea, continue magnetic stirring, then add 0.13gCTAB, continue magnetic stirring, Then the mixture was transferred to the polytetrafluoroethylene lining of the stainless steel autoclave, kept at a temperature of 220°C for 24 hours, and naturally cooled to room temperature to generate the product, which was washed five times with deionized water and ethanol respectively, The product was then vacuum-dried at 60° C. for 12 hours to obtain a dried molybdenum disulfide / copper sulfide / cuprous oxide nanocomposite material. figure 1 The XRD pattern in shows that the synthesized composite includes three phases of molybdenum disulfide, copper sulfide and cuprous oxide. figure 2 The scanning electron microscope picture shown shows that its microscopic morphology is a core-shell structure.

Embodiment 2

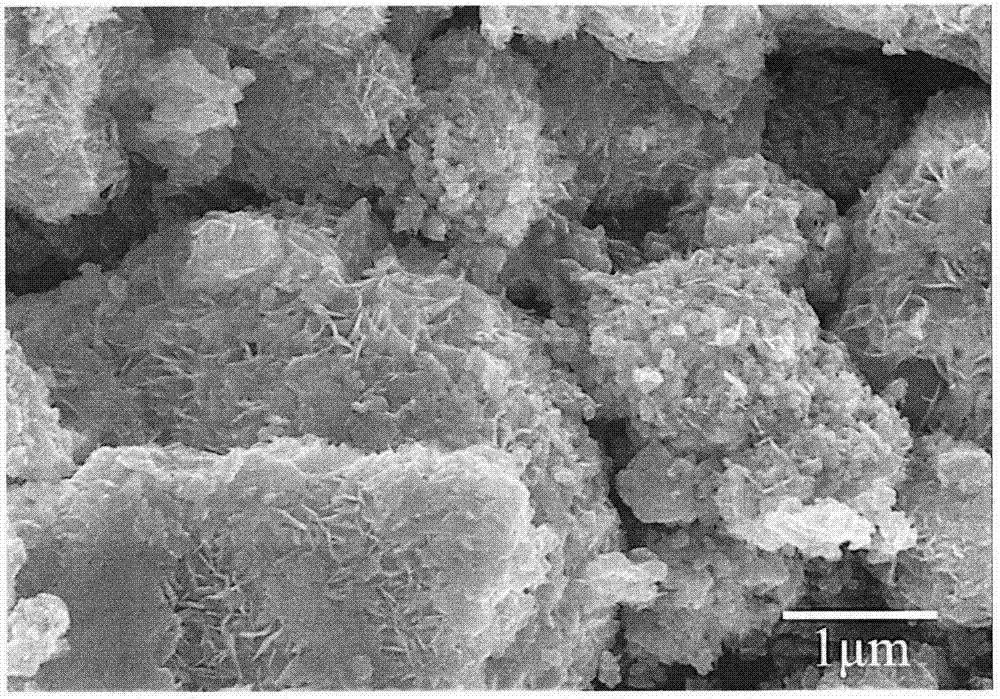

[0036] Add 0.35g copper oxide to deionized water, stir magnetically to obtain the mixture, then add 0.6g sodium molybdate dihydrate, continue magnetic stirring, then add 2.4g thiourea, continue magnetic stirring, then add 0.13gCTAB, continue magnetic stirring, Then the mixture was transferred to the polytetrafluoroethylene lining of the stainless steel autoclave, kept at a temperature of 220°C for 24 hours, and naturally cooled to room temperature to generate the product, which was washed five times with deionized water and ethanol respectively, The product was then vacuum-dried at 60° C. for 12 hours to obtain a dried molybdenum disulfide / copper sulfide / cuprous oxide nanocomposite material. figure 1 The XRD pattern in shows that the synthesized composite includes three phases of molybdenum disulfide, copper sulfide and cuprous oxide. image 3 The SEM pictures shown show the microscopic morphology of the composites.

Embodiment 3

[0038] Add 0.7g copper oxide to deionized water, stir magnetically to obtain the mixture, then add 0.6g sodium molybdate dihydrate, continue magnetic stirring, then add 2.4g thiourea, continue magnetic stirring, then add 0.13g CTAB, continue magnetic stirring, Then the mixture was transferred to the polytetrafluoroethylene lining of the stainless steel autoclave, kept at a temperature of 220°C for 24 hours, and naturally cooled to room temperature to generate the product, which was washed five times with deionized water and ethanol respectively, The product was then vacuum-dried at 60° C. for 12 hours to obtain a dried molybdenum disulfide / copper sulfide / cuprous oxide nanocomposite material. figure 1 The XRD pattern in shows that the synthesized composite includes three phases of molybdenum disulfide, copper sulfide and cuprous oxide. Figure 4 The SEM pictures shown show the microscopic morphology of the composites.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com