Premixed calcium silicate based root canal filling material with suspension stability as well as preparation method and application thereof

A technology of suspension stability and filling materials, applied in dental preparations, pharmaceutical formulations, medical science, etc., can solve the problems of ineffective regulation of dental pulp cell differentiation and induction of dentin bridges, easy degradation and loss of organic dispersants, and no chemical bonding, etc. problem, to achieve the effect of shortening the setting time, excellent edge sealing, and good biological activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

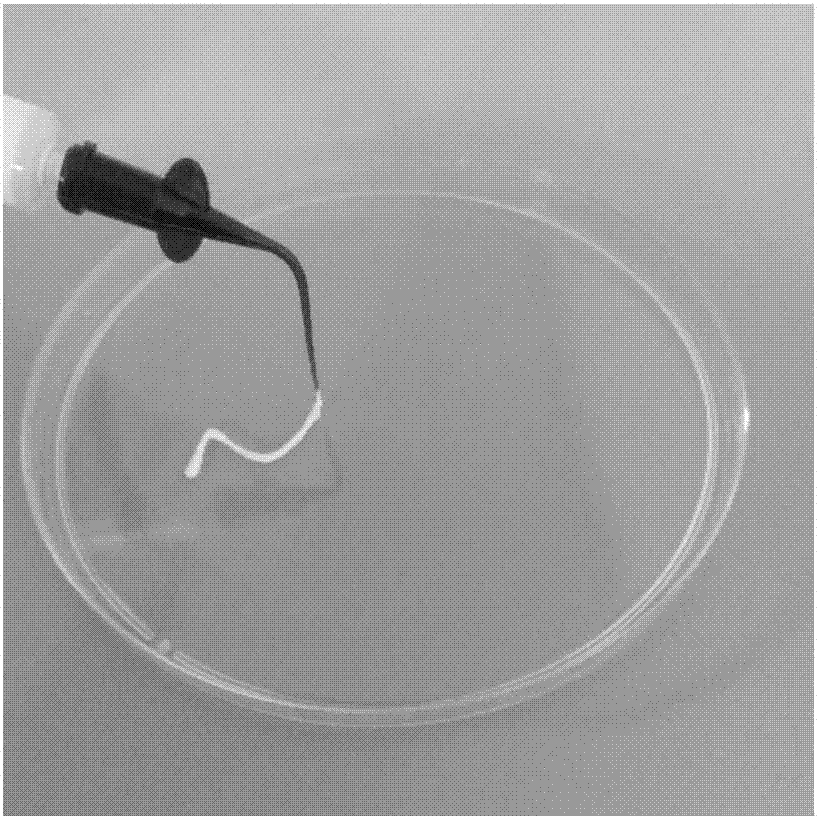

[0039] Embodiment 1, preparation of premixed suspension stable calcium sulfate hemihydrate / calcium silicate compound paste

[0040] 1. Raw material preparation:

[0041] Calcium sulfate hemihydrate is prepared by drying and dehydrating calcium sulfate dihydrate, that is, after grinding calcium sulfate dihydrate, heat it in an oven at 150°C for 12 hours, then adjust the temperature of the oven to 60°C, and age for 6 hours. 300 mesh sieve.

[0042] The calcium silicate compound is a mixture of tricalcium silicate and dicalcium silicate.

[0043] Glycerin is selected as the water-miscible non-aqueous solvent.

[0044] Zirconia powder is selected as the anti-radiation material.

[0045] The suspension stabilizer is fumed silica.

[0046] 2. Compound paste preparation:

[0047] Weigh 0.3g calcium sulfate hemihydrate, 0.56g tricalcium silicate, 0.14g dicalcium silicate, 0.96g zirconia, 0.04g fumed silica, 1mL glycerin, put them into a glass container, and use a stainless steel ...

Embodiment 2

[0049] Embodiment 2, preparation of premixed suspension-stabilized magnesium phosphate / calcium silicate compound paste

[0050] 1. Raw material preparation:

[0051] Magnesium phosphate bone cement powder, including dead burnt magnesia, sodium dihydrogen phosphate. Dead-burned magnesia is obtained by calcining light magnesia at 1500°C for 2 hours, and sodium dihydrogen phosphate is directly used as a purchased reagent. Dead burnt magnesium oxide and sodium dihydrogen phosphate were ball milled for 12 hours respectively, and passed through a 400 sieve. Dead burnt magnesium oxide and sodium dihydrogen phosphate according to the molar ratio of 3.8:1, ball milling and mixing for 12 hours to prepare magnesium phosphate powder.

[0052] As the calcium silicate compound, wind crushed grade tricalcium silicate is selected.

[0053] The water-miscible non-aqueous solvent is 1,2-propanediol.

[0054] Bismuth oxide powder is selected as the anti-radiation material.

[0055] Suspension...

Embodiment 3

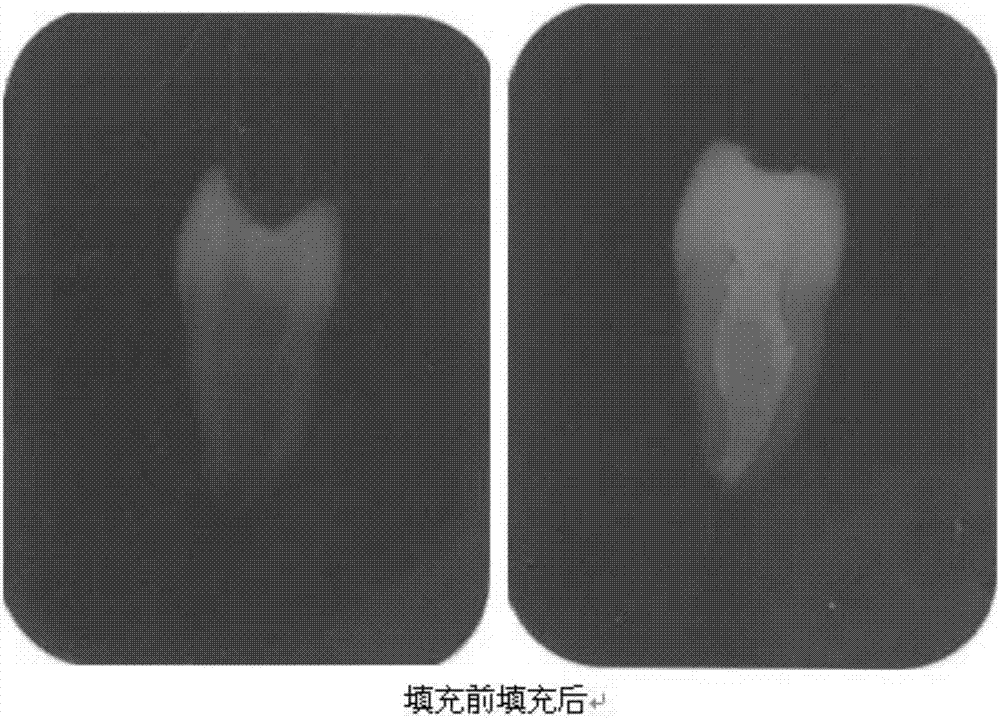

[0059] Embodiment 3, the curing time of composite paste

[0060] 1. Paste preparation:

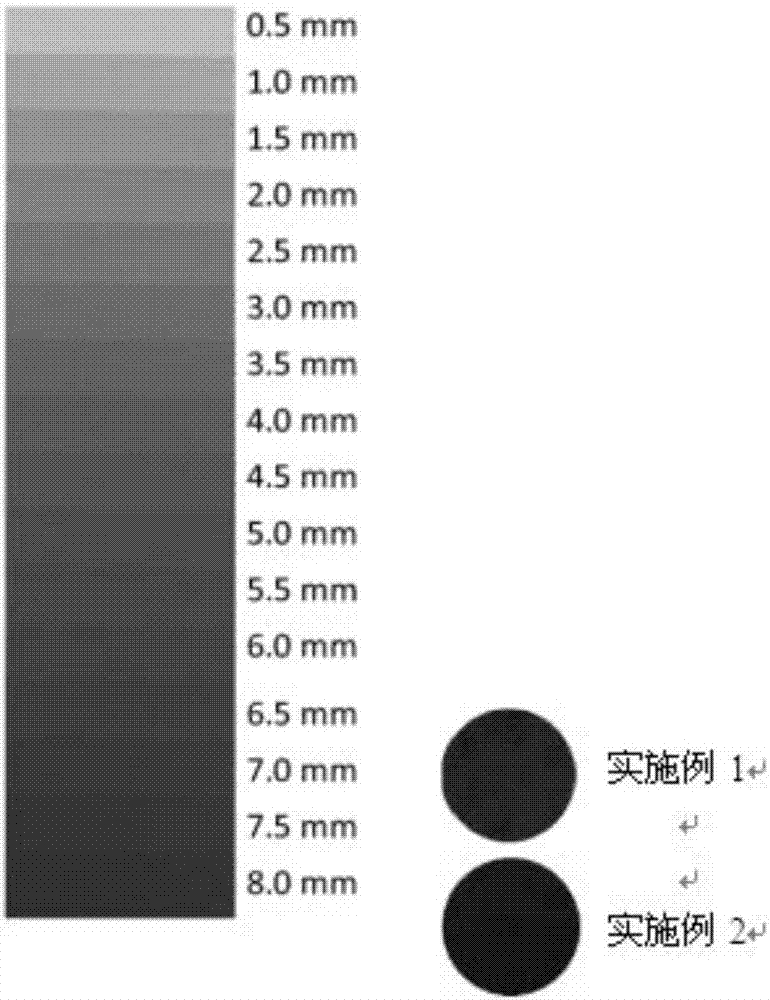

[0061] Experimental group: the composite paste prepared in Example 1 and Example 2.

[0062] Control group 1: Weigh 0.8g tricalcium silicate, 0.2g dicalcium silicate, 0.96g zirconia, 0.04g fumed silica, 1mL glycerin, put them into a glass container, and fully reconcile them with a stainless steel stirring rod for 5 minutes to obtain Premixed calcium silicate based compound paste.

[0063] Control group 2: Weigh 1g tricalcium silicate, 0.95g bismuth oxide, 0.05g organobentonite, 0.8mL 1,2-propylene glycol, and mix them in a planetary ball mill for 10 minutes to obtain a premixed tricalcium silicate composite paste .

[0064] 2. Curing time test:

[0065] The test method selects the test method specified in the industry standard YY0717-2009. Fill the paste prepared above into a hydrated plaster mold, put it into a constant temperature and humidity chamber with a temperature of 37°C and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com