Powder metallurgy brake pad for D-series high-speed train set

A powder metallurgy, EMU technology, applied in the direction of friction linings, mechanical equipment, etc., can solve the problems of difficult to guarantee the size of stamping, affecting the braking performance of the brake pads, and easy failure of the cotter pin to prevent rotation, so as to improve reliability and reliability. Safety, improve the life and reliability of the brake pad, the effect of simple and reliable anti-rotation structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

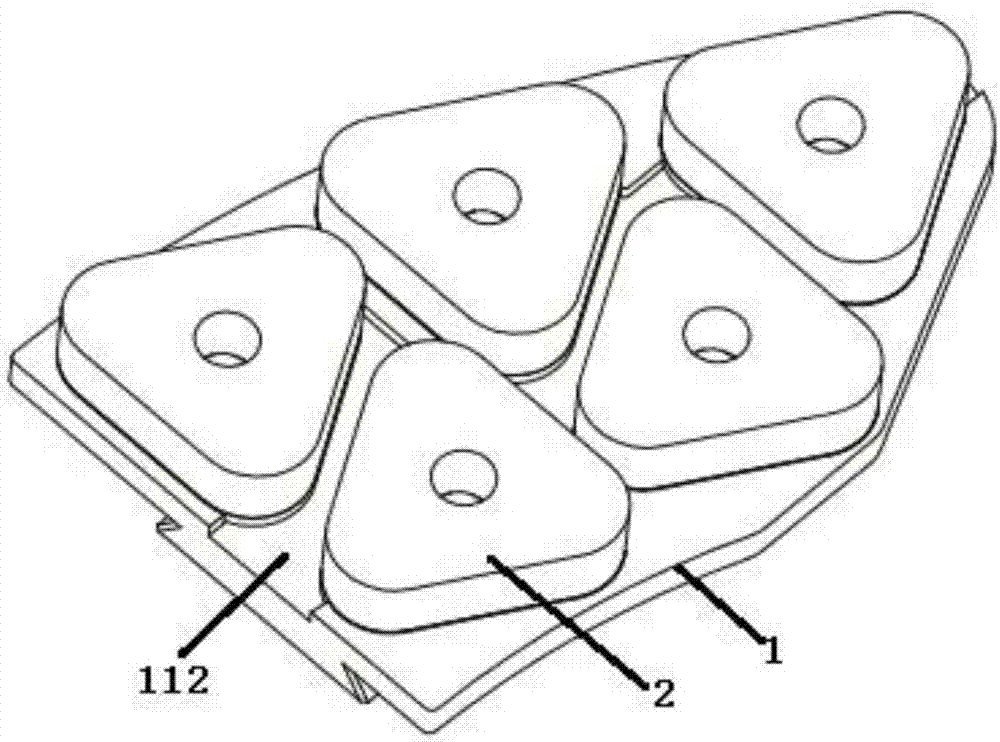

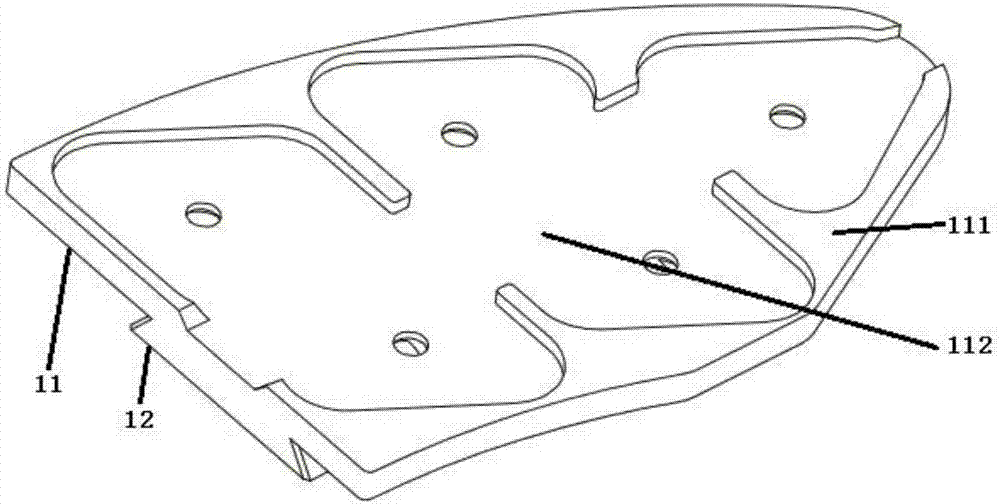

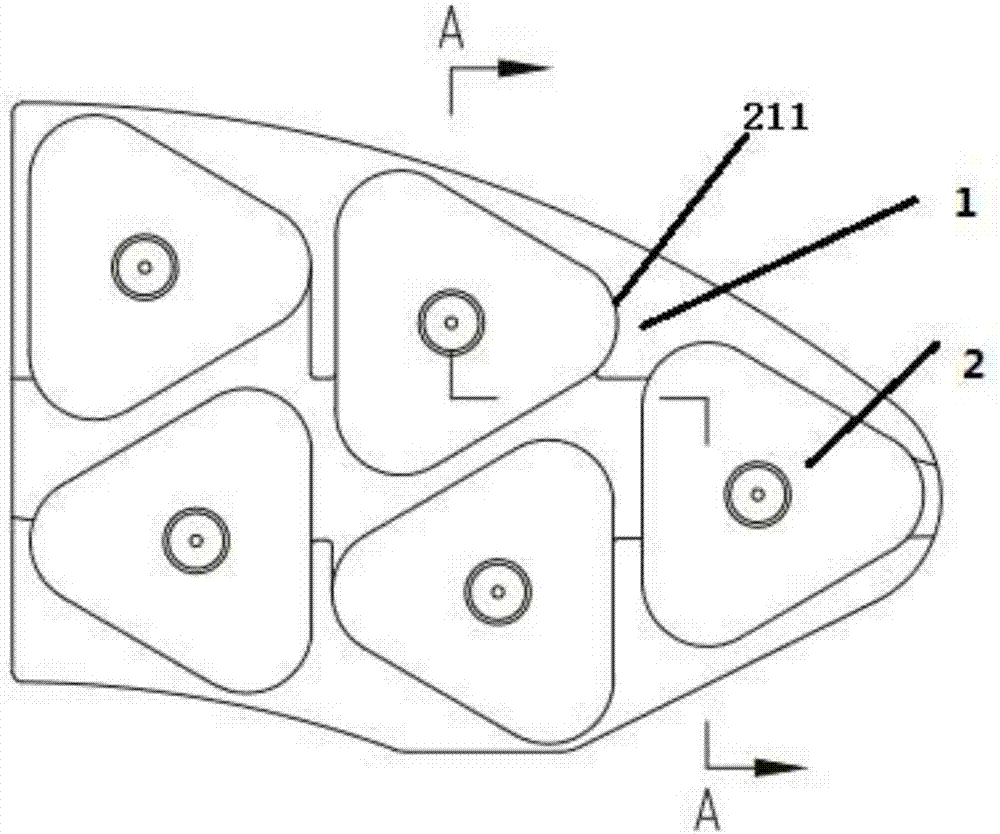

[0039] This embodiment discloses a powder metallurgy brake pad for an EMU, such as Figure 1-Figure 8 As shown, it includes a steel back 1 and five brake pad friction bodies 2, wherein the steel back 1 includes an integrally formed steel back plate 11 and a dovetail block 12, the steel back 1 is an irregular polygonal structure, and is made of special ductile iron , Machined after casting. The use of ductile iron can absorb the vibration of the brake pads during braking, and has obvious effects on reducing noise and improving the fatigue life of the brake pads. The center of the brake pad friction body 2 and the corresponding steel back plate 11 are provided with matching stepped holes, and are connected to each other by the rivets 3 provided there...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com