Dyeing and finishing process of polyester-cotton interwoven fabric

A fabric and polyester-cotton technology, applied in the field of dyeing and finishing, can solve the problems of poor wearability, poor printing and dyeing performance, and monotonous style of polyester-cotton interwoven fabrics, so as to improve strength and appearance flatness, improve the ability to absorb dyes, increase The effect of dimensional stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

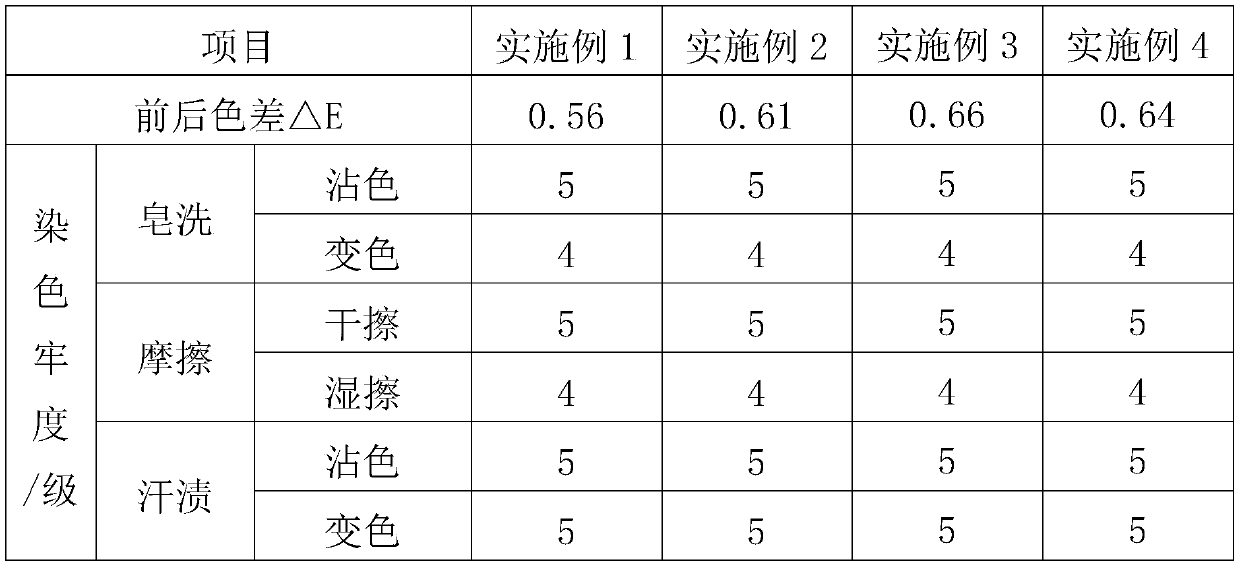

Examples

Embodiment 1

[0021] In the present embodiment, a dyeing and finishing process of polyester-cotton interwoven fabric comprises the following steps:

[0022]S1, pretreatment, padding the polyester-cotton interwoven fabric at room temperature with the working liquid, two dipping and two rolling, the excess rate is 75%, the working liquid includes: caustic soda 35g / L, hydrogen peroxide 12g / L, penetrant 3g / L , refining agent 10g / L, chelating dispersant 3g / L, hot wash after stacking at room temperature for 12h, then immerse in the enzyme treatment solution, and treat at 45°C for 55min, the enzyme treatment solution includes: amylase 7g / L, fruit Gluease 3g / L, cellulase 2g / L, laccase 1g / L, urea 1.5g / L, hot wash at 75°C and then dry;

[0023] S2, pre-setting, carry out pre-setting treatment on the polyester-cotton interwoven fabric after S1 pretreatment, add anti-yellowing agent 9g / L when finalizing, setting temperature is 155 ℃, vehicle speed is 25m / min, overfeed 7%;

[0024] S3, dyeing, immersin...

Embodiment 2

[0027] In the present embodiment, a dyeing and finishing process of polyester-cotton interwoven fabric comprises the following steps:

[0028] S1, pretreatment, padding the polyester-cotton interwoven fabric at room temperature with the working solution, two dipping and two rolling, the excess rate is 60%, the working solution includes: caustic soda 40g / L, hydrogen peroxide 10g / L, penetrant 5g / L , refining agent 8g / L, chelating dispersant 5g / L, hot wash after stacking at room temperature for 10h, then immerse in the enzyme treatment solution, and treat at 60°C for 30min, the enzyme treatment solution includes: amylase 10g / L, fruit Glue enzyme 1g / L, cellulase 5g / L, urea 2.5g / L, heat wash at 50°C and dry, then immerse in the oxygen bleaching treatment solution, treat at 100°C for 20min, wash with water at 95°C and dry, the Oxygen bleaching solution includes: caustic soda 0.5g / L, hydrogen peroxide 20g / L, stabilizer 0.5g / L;

[0029] S2, pre-setting, carry out pre-setting treatmen...

Embodiment 3

[0035] In the present embodiment, a dyeing and finishing process of polyester-cotton interwoven fabric comprises the following steps:

[0036] S1, pretreatment, padding the polyester-cotton interwoven fabric at room temperature with the working solution, two dipping and two rolling, the excess rate is 90%, the working solution includes: caustic soda 30g / L, hydrogen peroxide 15g / L, penetrant 1g / L , refining agent 12g / L, chelating dispersant 1g / L, stacked at room temperature for 15h, then hot-washed, then immersed in the enzyme treatment solution, and treated at 30°C for 80min, the enzyme treatment solution includes: amylase 5g / L, fruit Gluease 5g / L, cellulase 0.01g / L, laccase 5g / L, urea 0.5g / L, hot wash at 100°C, dry, then immerse in oxygen bleaching solution, treat at 80°C for 60min, 90°C Drying after washing, the oxygen bleaching treatment liquid includes: caustic soda 5g / L, hydrogen peroxide 0.5g / L, stabilizer 5g / L;

[0037] S2, pre-setting, carry out pre-setting treatment ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com