Rare earth high-entropy bulk amorphous alloy with magnetothermal effect and preparation process thereof

An amorphous alloy, rare earth high-entropy technology, applied in magnetic objects, heat exchange materials, magnetic materials, etc., can solve problems such as hindering the movement of magnetic domain walls and reducing magnetic properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] Preparation (La 1 / 6 Ce 1 / 6 Nd 1 / 6 Tb 1 / 6 co 1 / 6 Cu 1 / 6 ) 85.7 Al 14.3 High entropy bulk amorphous alloy

[0046] Step 1: be 99.5wt% La, Ce, Nd, Tb with purity, 99.9wt% Al and 99.9wt% Cu and Co according to (La 1 / 6 Ce 1 / 6 Nd 1 / 6 Tb 1 / 6 co 1 / 6 Cu 1 / 6 ) 85.7 Al 14.3 The atomic percentage is used for batching;

[0047] Step 2: Mix the above ingredients evenly and put them into an electric arc furnace, perform electric arc melting for 4 times in an argon atmosphere adsorbed by titanium to obtain a uniform alloy composition, and cool to obtain a master alloy ingot;

[0048] Step 3: re-melting the master alloy ingot obtained above under the above conditions, using the adsorption device in the electric arc furnace, sucking the master alloy melt into a water-cooled copper mold with an inner diameter of 5 mm to obtain (La 1 / 6 Ce 1 / 6 Nd 1 / 6 Tb 1 / 6 co 1 / 6 Cu 1 / 6 ) 85.7 Al 14.3 High-entropy bulk amorphous alloys.

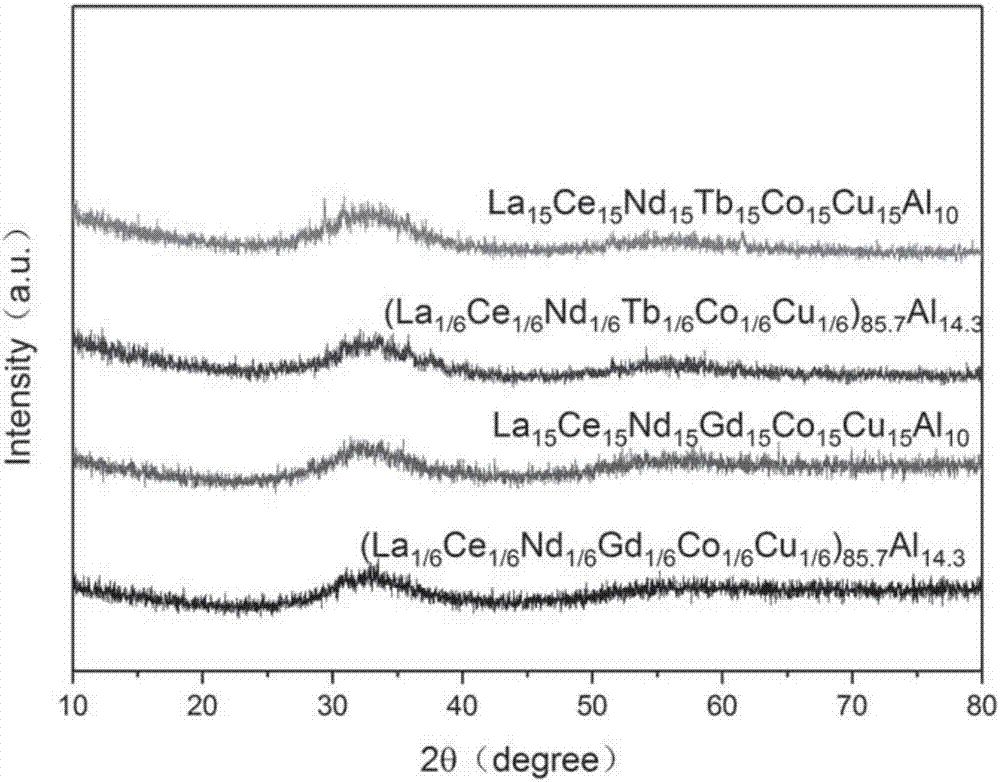

[0049] The structural features of high-entro...

Embodiment 2

[0051] Embodiment 2: prepare La 15 Ce 15 Nd 15 Tb 15 co 15 Cu 15 Al 10 High entropy bulk amorphous alloy

[0052] Step 1: La, Ce, Nd, Tb with a purity of 99.5wt%, 99.9wt% of Al and 99.9wt% of Cu and Co according to La 15 Ce 15 Nd 15 Tb 15 co 15 Cu 15 Al 10 Atomic percentage for batching;

[0053] Step 2: Mix the above ingredients evenly and put them into an electric arc furnace, perform electric arc melting 4 times in an argon atmosphere adsorbed by titanium to obtain a uniform alloy composition, and cool to obtain a master alloy ingot;

[0054] Step 3: re-melt the master alloy ingot obtained above under the above conditions, and use the adsorption device in the electric arc furnace to suck the master alloy melt into a water-cooled copper mold with an inner diameter of 5 mm to obtain La 15 Ce 15 Nd 15 Tb 15 co 15 Cu 15 Al 10 High-entropy bulk amorphous alloys.

[0055] The structural features of high-entropy bulk amorphous alloys were detected by X-ray dif...

Embodiment 3

[0057] Embodiment 3: preparation (La 1 / 6 Ce 1 / 6 Nd 1 / 6 Gd 1 / 6 co 1 / 6 Cu 1 / 6 ) 85.7 Al 14.3 High entropy bulk amorphous alloy

[0058] Step 1: be 99.5wt% La, Ce, Nd, Gd with purity, 99.9wt% Al and 99.9wt% Cu and Co according to (La 1 / 6 Ce 1 / 6 Nd 1 / 6 Gd 1 / 6 co 1 / 6 Cu 1 / 6 ) 85.7 Al 14.3 Atomic percentage for batching;

[0059] Step 2: Mix the above ingredients evenly and put them into an electric arc furnace, perform electric arc melting 4 times in an argon atmosphere adsorbed by titanium to obtain a uniform alloy composition, and cool to obtain a master alloy ingot;

[0060] Step 3: re-melting the master alloy ingot obtained above under the above conditions, using the adsorption device in the electric arc furnace, sucking the master alloy melt into a water-cooled copper mold with an inner diameter of 5 mm to obtain (La 1 / 6 Ce 1 / 6 Nd 1 / 6 Gd 1 / 6 co 1 / 6 Cu 1 / 6 ) 85.7 Al 14.3 High-entropy bulk amorphous alloys.

[0061] The structural features of high-entropy...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com