Full-automatic rice steamer loading robot for evenly paving materials

A fully automatic and robotic technology, which is used when retorting in the liquor brewing process. , The field of mechanical system that automatically completes the brewing materials, can solve the problems of high labor intensity, affecting the quality of wine, and easy to form agglomerates, so as to reduce labor intensity, avoid adverse effects, and prevent overflow.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

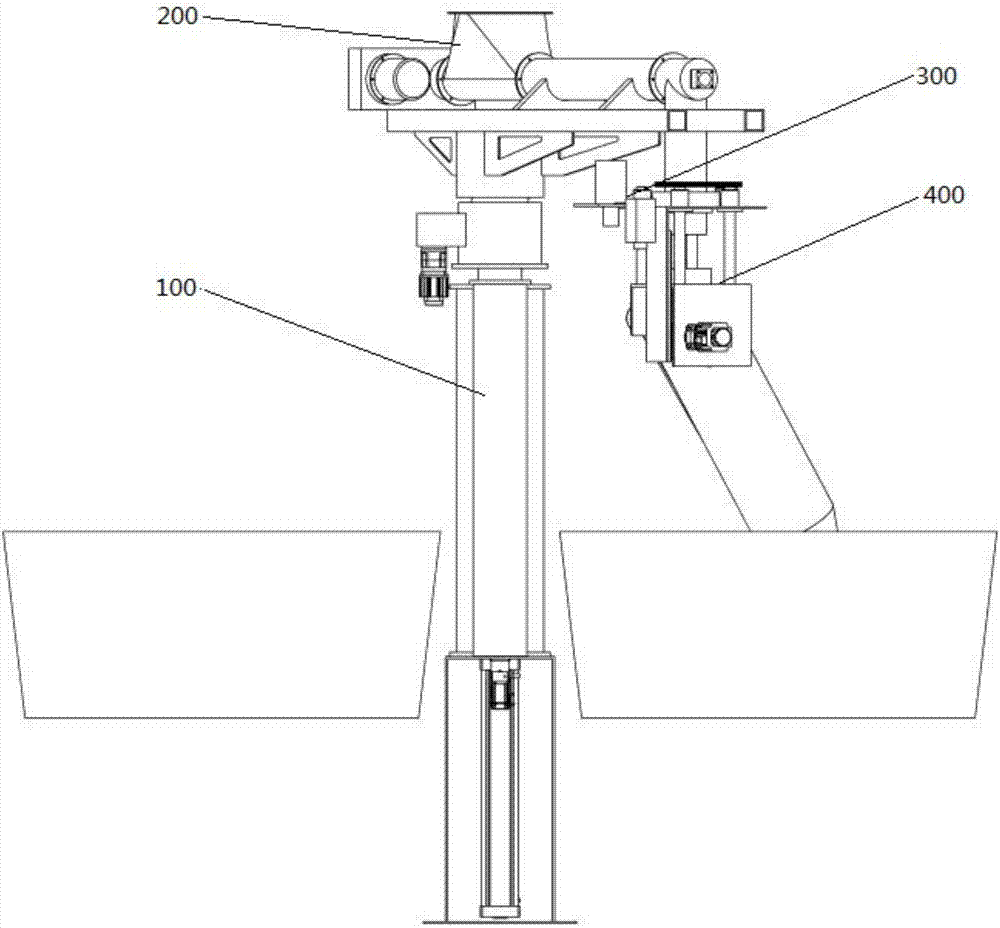

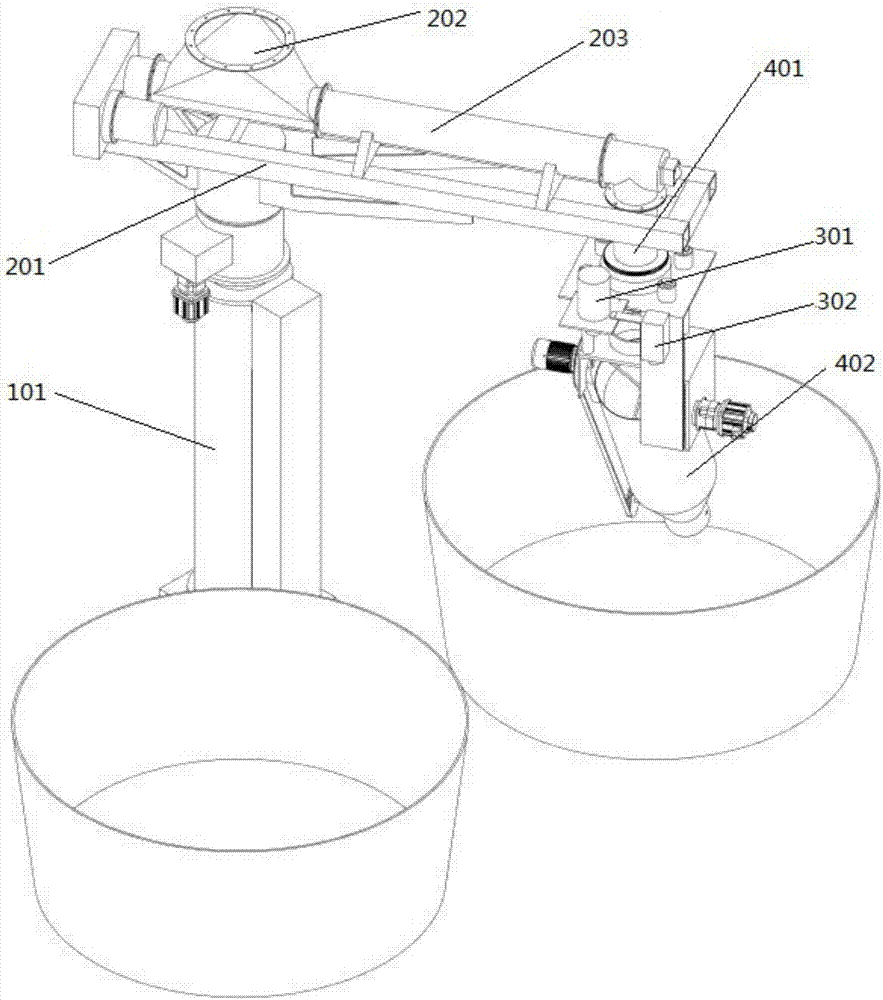

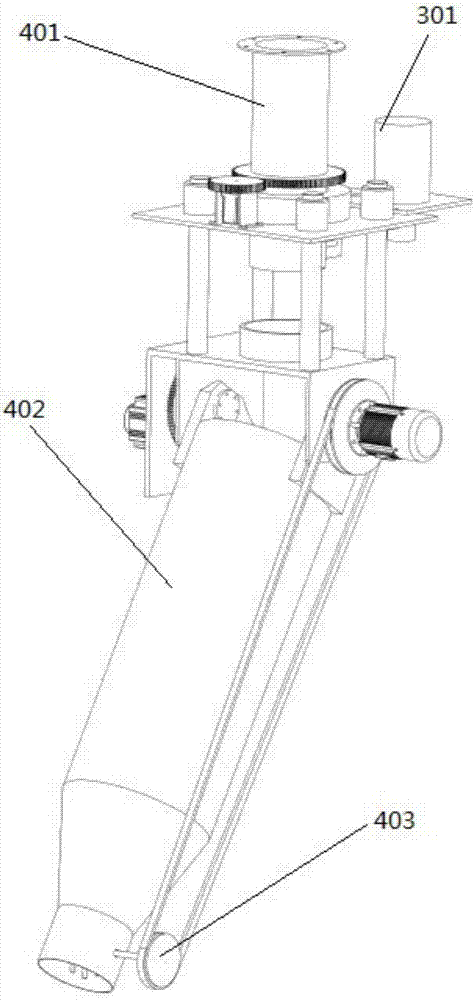

[0022] Such as figure 2 As shown, the front transportation system continuously transports the fermented wine-making material to the hopper 202 of the present invention. After the wine-making material enters the hopper 202, it reaches the material-spreading head cantilever 401 under the conveyance of the screw conveying device inside the feeding pipe 203. above, such as Figure 4 As shown, the cantilever 401 of the spreading head is hollow, and the brewing material enters the inside of the spreading head 402 from the feeding pipe 203 through the cantilever 401 of the spreading head, and is conveyed by the screw conveyor 404 inside the spreading head. The output of the material opening controls the start-stop and rotation speed of the screw conveying device 404 inside the material spreading head, which can accurately control the output of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com