Composite structure ceramic proppant and preparation method thereof

A composite structure and proppant technology, applied in the production of ceramic materials, chemical instruments and methods, earthwork drilling and mining, etc., can solve the problems of high sintering temperature, high product density, high energy consumption, etc. The effect of mechanical strength and process method is simple and easy to implement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

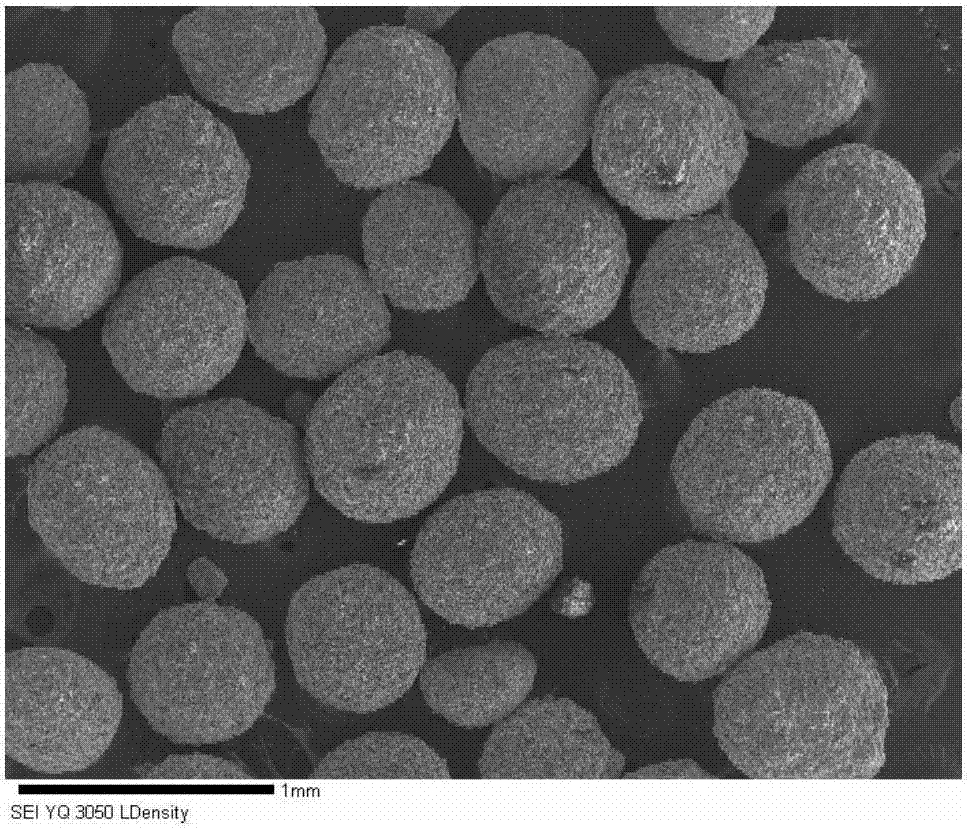

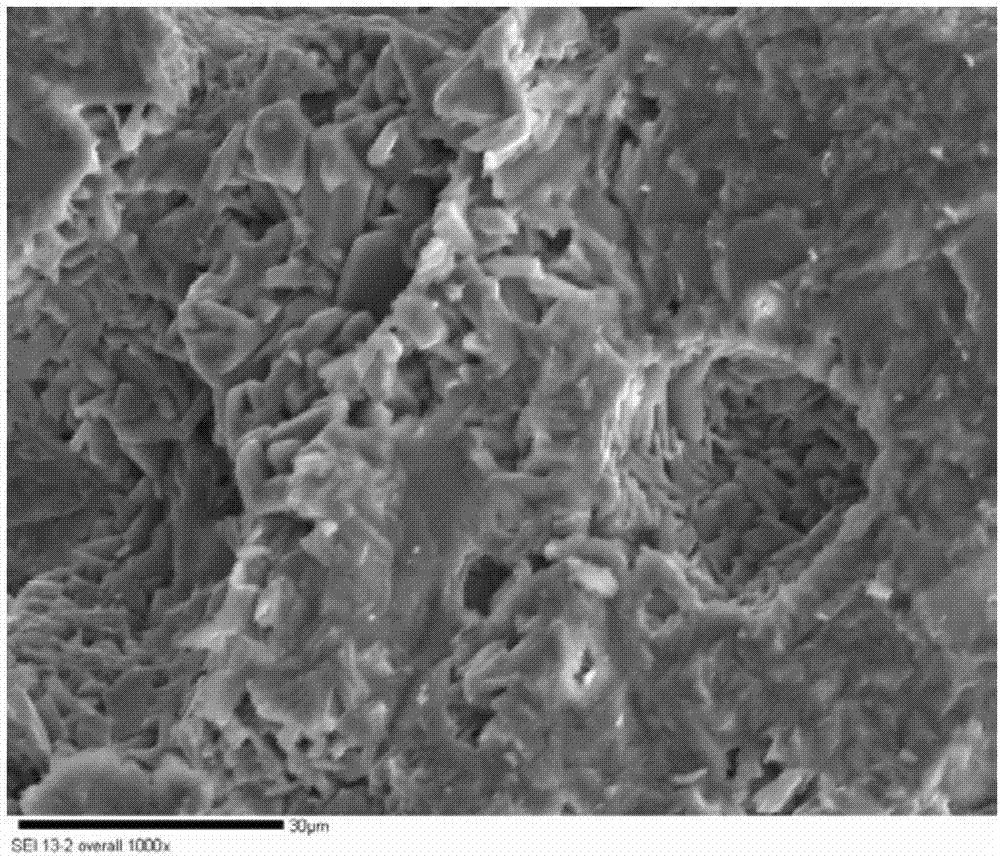

Image

Examples

Embodiment 1

[0039] A ceramic proppant with a composite structure, which contains the following components and mass percentages: steel slag: 63.8%, fly ash: 5%, kyanite micropowder: 8%, silica micropowder: 8%, clay: 15%, carboxylate Methylcellulose: 0.2%.

[0040] Carry out following process step operation according to the mass percent content of above-mentioned each component:

[0041]1) Preparation of powder: the cooled steel slag (open-hearth slag of WISCO is preferred in this embodiment) is sequentially crushed, dried, pulverized, ground and mixed uniformly to obtain steel slag powder, and the particle size of the steel slag powder is 75 μm or less , the present embodiment is preferably 75 μm; fly ash and clay (preferred kaolin in this embodiment) are pulverized, ground and mixed uniformly to obtain fly ash powder and clay powder respectively, ensuring that the particle size of fly ash powder is 75 μm or 75 μm Hereinafter, in this embodiment, it is preferably 75 μm, and the particle s...

Embodiment 2

[0050] A ceramic proppant with a composite structure, which contains the following components and mass percentages: steel slag: 69.5%, fly ash: 15%, kyanite micropowder: 5%, silica micropowder: 5%, clay: 5%, carboxylate Methylcellulose: 0.5%.

[0051] Carry out following process step operation according to the mass percent content of above-mentioned each component:

[0052] 1) Preparation of powder: the cooled steel slag (the converter slag of Wuhan Iron and Steel Co., Ltd. is preferred in this embodiment) is sequentially crushed, dried, pulverized, ground and mixed uniformly to obtain steel slag powder, and the particle size of the steel slag powder is below 60 μm; Fly ash and clay (the preferred bentonite in this embodiment) are pulverized, ground and mixed uniformly to obtain fly ash powder and clay powder respectively, ensuring that the particle diameter of fly ash powder is below 60 μm, and the particle diameter of clay powder is below 40 μm;

[0053] 2) batching: gettin...

Embodiment 3

[0061] A ceramic proppant with a composite structure, which contains components and mass percentages: steel slag: 74.5%, fly ash: 10%, kyanite micropowder: 5%, silica micropowder: 5%, clay: 5%, carboxylate Methylcellulose: 0.5%.

[0062] Carry out following process step operation according to the mass percent content of above-mentioned each component:

[0063] 1) Preparation of powder: the cooled steel slag (the electric furnace slag of Wuhan Iron and Steel Co., Ltd. is preferred in this embodiment) is sequentially crushed, dried, pulverized, ground and mixed uniformly to obtain steel slag powder, and the particle size of the steel slag powder is below 75 μm; Fly ash and clay (preferred illite in this embodiment) are pulverized, ground and mixed evenly to obtain fly ash powder and clay powder respectively, ensuring that the particle diameter of fly ash powder is below 75 μm, and the particle diameter of clay powder is below 45 μm ;

[0064] 2) batching: getting mass percent ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com