High-performance white porcelain body and preparation method thereof

A high-performance, body-based technology, which is applied to clay products, strength characteristics, and other household appliances, can solve problems such as difficult to guarantee product performance indicators, easy deformation and brittleness of products, and influence on product competitiveness, so as to achieve easy industrialization and popularization. Application, expansion of sintering temperature range, and convenient production and implementation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described in detail below in conjunction with embodiments.

[0023] Those skilled in the art will understand that the following examples are only used to illustrate the present invention and should not be regarded as limiting the scope of the present invention.

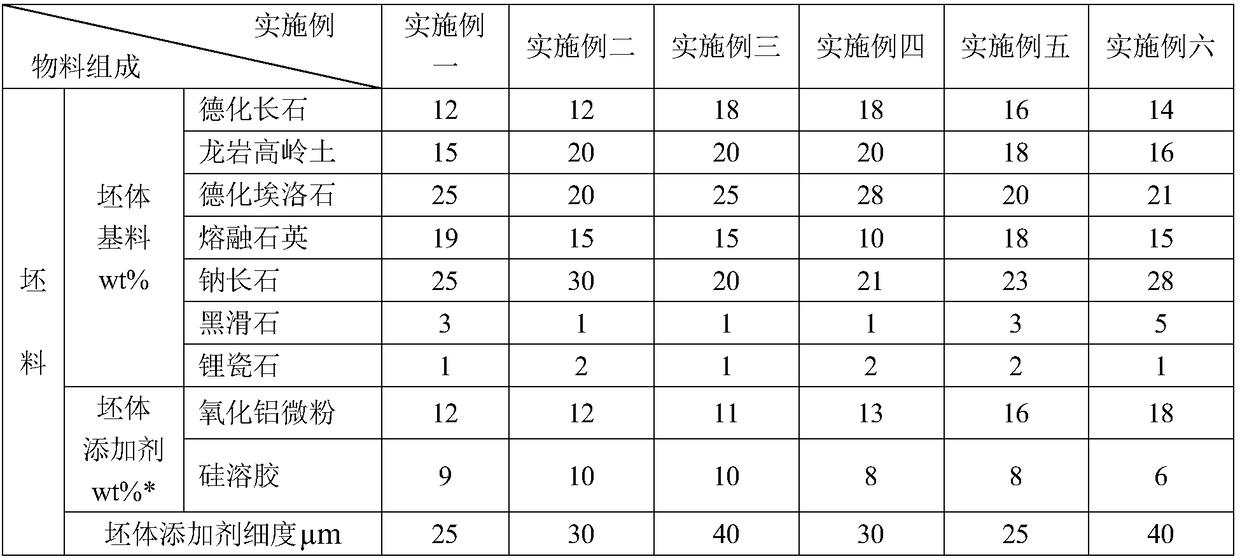

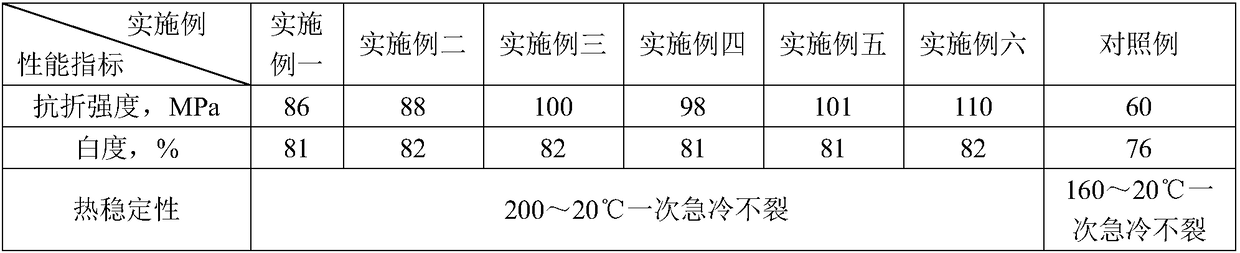

[0024] The material composition of the high-performance white porcelain body of each embodiment of the present invention is shown in Table 1:

[0025] Table 1 Material composition of the high-performance Dehua white porcelain body in the embodiment of the present invention

[0026]

[0027] *The amount of body additives is relative to the amount of body base material.

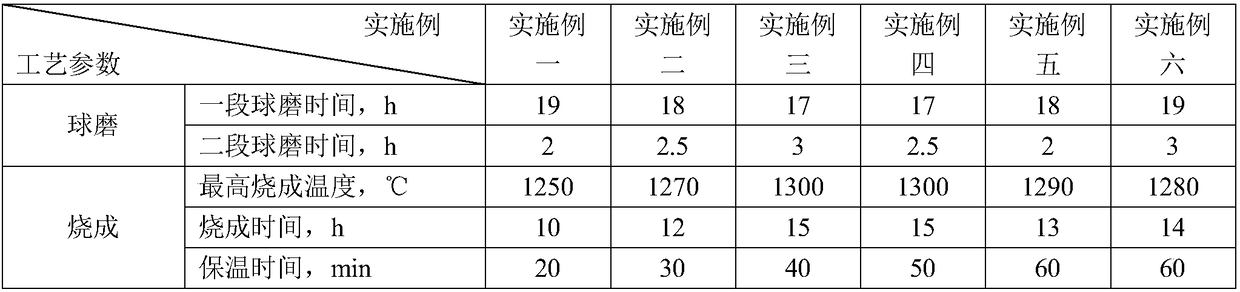

[0028] The process parameters for preparing high-performance white porcelain in each embodiment of the present invention are shown in Table 2:

[0029] Table 2 Process parameters of the high-performance white porcelain preparation method of the embodiment of the present invention

[0030]

[0031] Note: The firing time ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

| thermal stability | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com