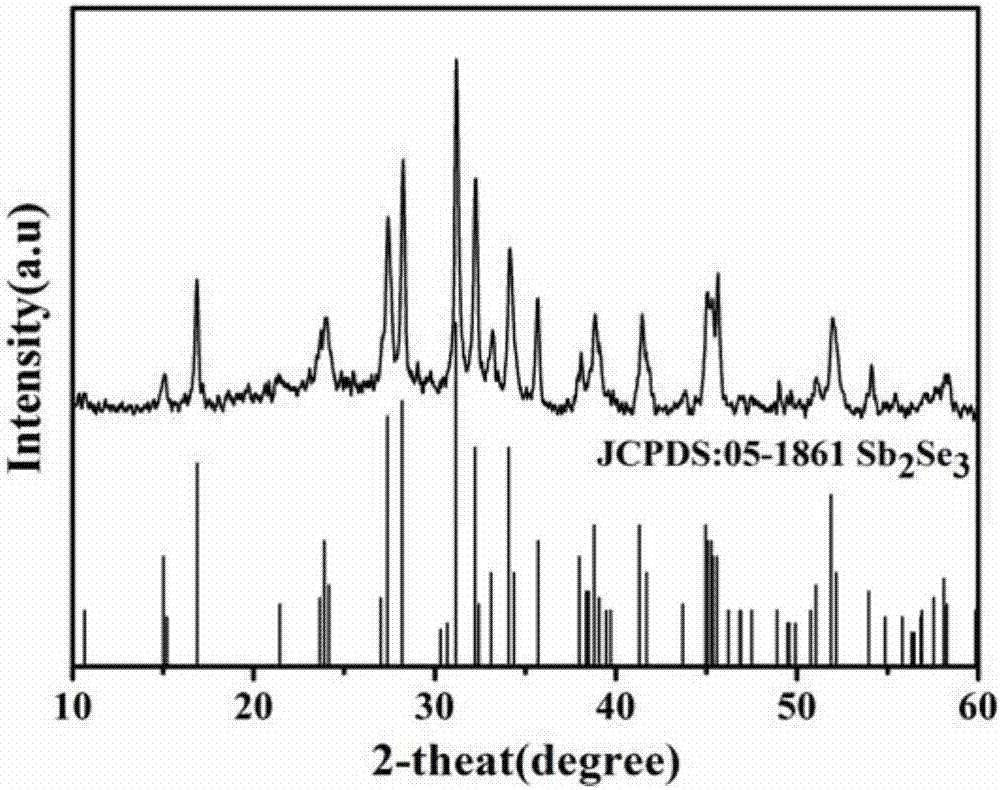

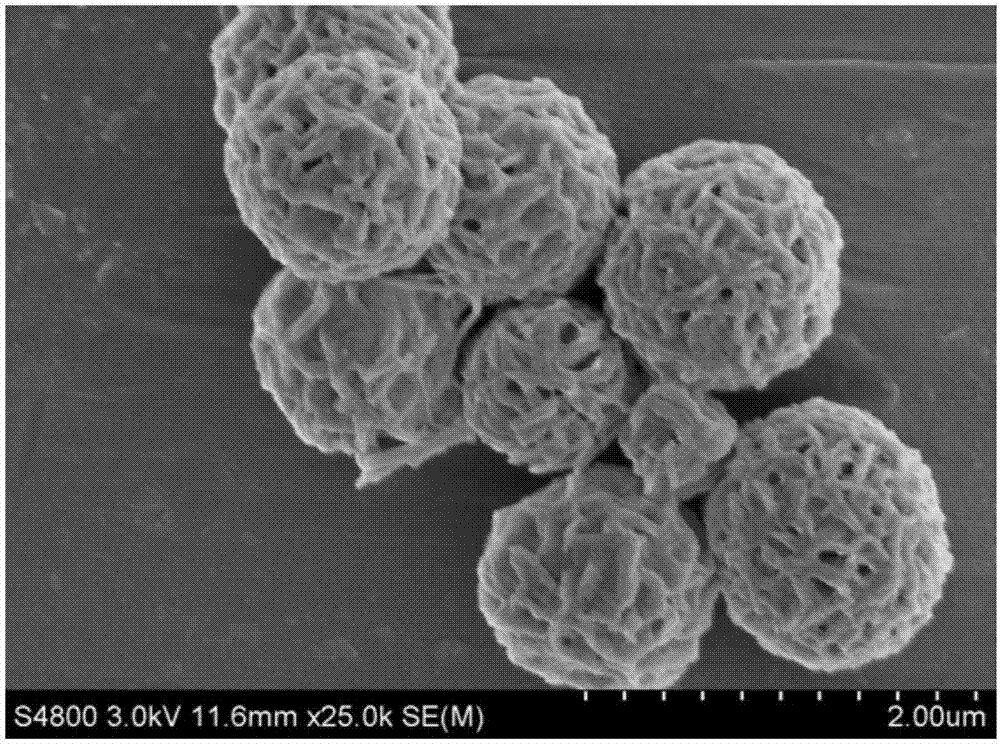

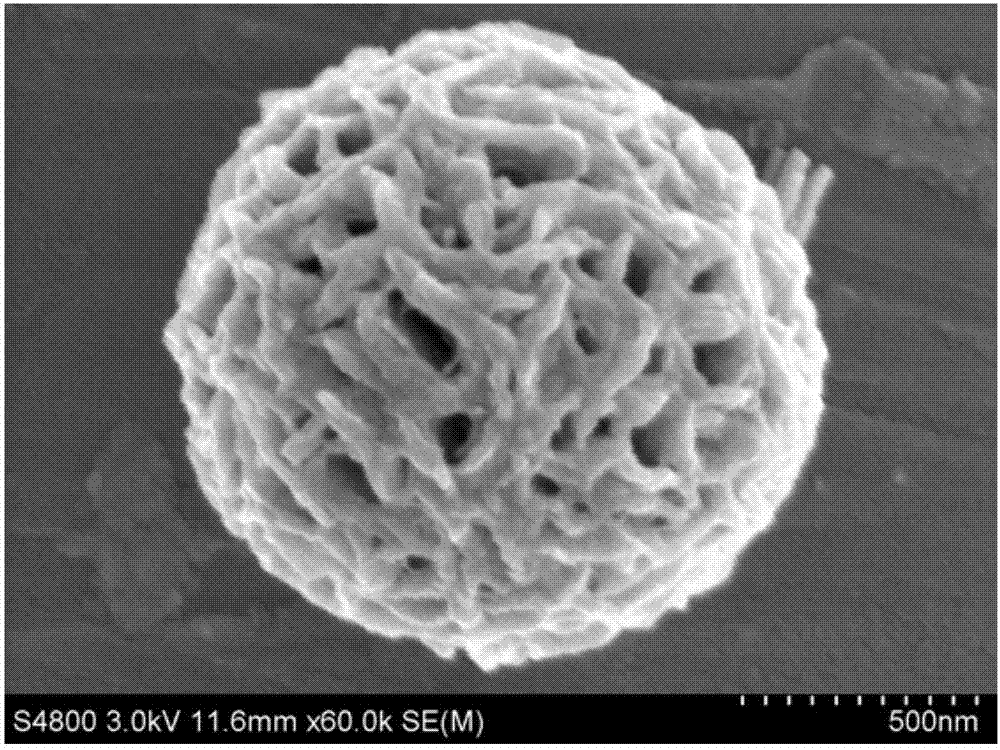

Method for preparing nanowire-woven spherical Sb2Se3 (antimony selenide) sodium-ion battery anode material

A technology of sodium antimony selenide, ion battery, applied in battery electrodes, negative electrodes, secondary batteries and other directions, can solve problems such as hindering the study of electrochemical behavior of electrode materials, large environmental pollution, and easy occurrence of danger, and achieve excellent electrochemical performance. Performance, temperature range, no water vapor pollution, stable heating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] 1) Add polyvinylpyrrolidone and antimony potassium tartrate with an average molecular weight of 30000 to the mixture of ethylene glycol and distilled water, stir (500r / min, 60min) to completely dissolve it, and obtain solution A, in which ethylene glycol and distilled water The volume ratio is V 乙二醇 :V 蒸馏水 =4:1, the concentration of potassium antimony tartrate is 0.001mol / L, the addition of polyvinylpyrrolidone is 0.05g, and the addition of potassium antimony tartrate is 0.0236g;

[0030] 2) Add 0.0179g of sodium selenite into 2mL of hydrazine hydrate with a mass concentration of 50%, stir (500r / min, 20min) to completely dissolve it, and obtain wine red solution B;

[0031] 3) Add the obtained solution B to the solution A dropwise under stirring (500r / min) to obtain the mixed solution C;

[0032]4) First, add three drops (1mL) of glycerin to the mixture C under stirring (500r / min), stir evenly, put it into an oil bath, and isolate the air at a temperature of 80°C for ...

Embodiment 2

[0034] 1) Add polyvinylpyrrolidone and antimony potassium tartrate with an average molecular weight of 30000 to the mixture of ethylene glycol and distilled water, stir (500r / min, 30min) to completely dissolve it, and obtain solution A, the volume of ethylene glycol and distilled water than controlled at V 乙二醇 :V 蒸馏水 =1:1, the concentration of potassium antimony tartrate is 0.005mol / L, the addition of polyvinylpyrrolidone is 0.1g, and the addition of potassium antimony tartrate is 0.1352g;

[0035] 2) Add 0.09g of sodium selenite into 4mL of hydrazine hydrate with a mass concentration of 50%, and stir (500r / min, 20min) to completely dissolve it to obtain wine red solution B;

[0036] 3) Add the obtained solution B to the solution A dropwise under stirring (500r / min) to obtain the mixed solution C;

[0037] 4) First, add three drops of glycerin (1mL) to the mixture C under stirring (700r / min), stir evenly, put it into an oil bath, and isolate the air at a temperature of 100°C...

Embodiment 3

[0039] 1) Add polyvinylpyrrolidone and antimony potassium tartrate with an average molecular weight of 30000 to the mixture of ethylene glycol and distilled water, stir (600r / min, 10min) to completely dissolve it, and obtain solution A, the volume of ethylene glycol and distilled water than controlled at V 乙二醇 :V 蒸馏水 =1:3, the concentration of potassium antimony tartrate is 0.010mol / L, the addition of polyvinylpyrrolidone is 0.15g, and the addition of potassium antimony tartrate is 0.2703g;

[0040] 2) Add 0.2075g of sodium selenite into 6mL of hydrazine hydrate with a mass concentration of 50%, and stir (600r / min, 20min) to completely dissolve it to obtain wine red solution B;

[0041] 3) The obtained solution B was added dropwise to the solution A under the condition of stirring (600r / min) to obtain the mixed solution C;

[0042] 4) First, add three drops of glycerin (1mL) to the mixture C under stirring (700r / min), stir evenly, put it in an oil bath, isolate the air, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com