MoSe2/Co0.85Se composite material for electrocatalytic water decomposition as well as preparation method and application thereof

A technology of co0.85se and composite materials, applied in chemical instruments and methods, electrolytic components, electrolytic processes, etc., can solve the problems of unpublished material stability related data, high cost of selenium dioxide, and inconspicuous catalytic effect, etc. Achieve the effect of facilitating subsequent application or testing, reducing energy and reducing impedance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

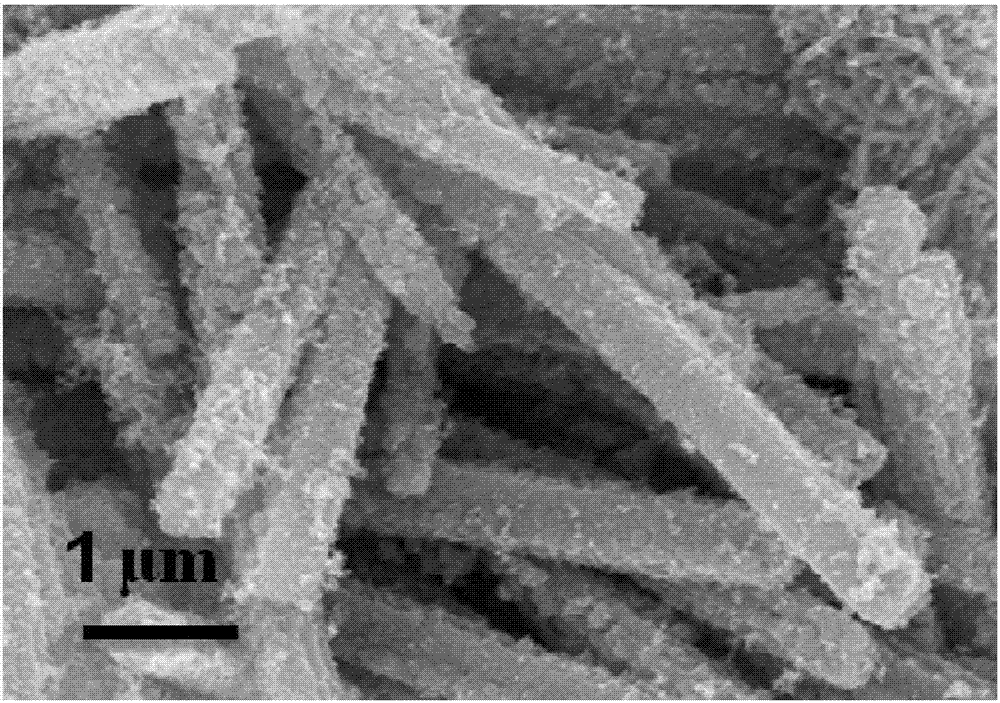

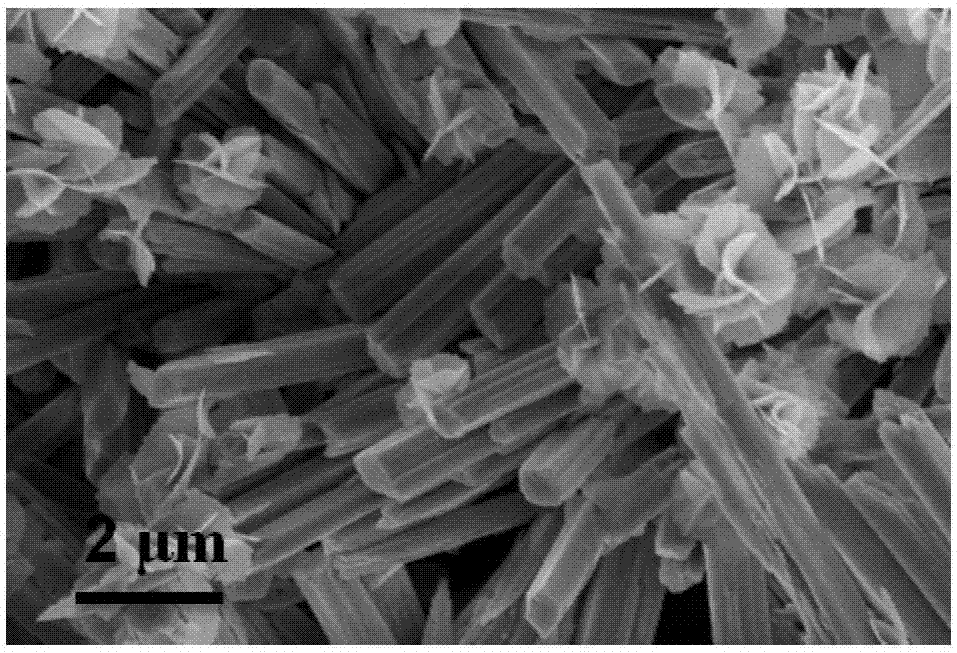

[0057] A kind of MoSe for electrocatalytic water splitting 2 / Co 0.85 Se composite material, this composite material comprises MoSe 2 and Co 0.85 Composite composed of Se, MoSe in the composite material 2 The mass content is 50%, Co 0.85 The mass content of Se is 30%; the microscopic morphology of the composite material is: MoSe 2 / Co 0.85 Molybdenum selenide / cobalt selenide composite nanosheets are loaded on the micro / nanorods of the Se composite.

[0058] The MoSe 2 and Co 0.85 The length of the micro / nanorods of the Se composite is 1.5–3.5 μm, and the average diameter of the rods is 0.3 μm.

[0059] The aforementioned MoSe for electrocatalytic water splitting 2 / Co 0.85 The preparation method of Se composite material, comprises steps as follows:

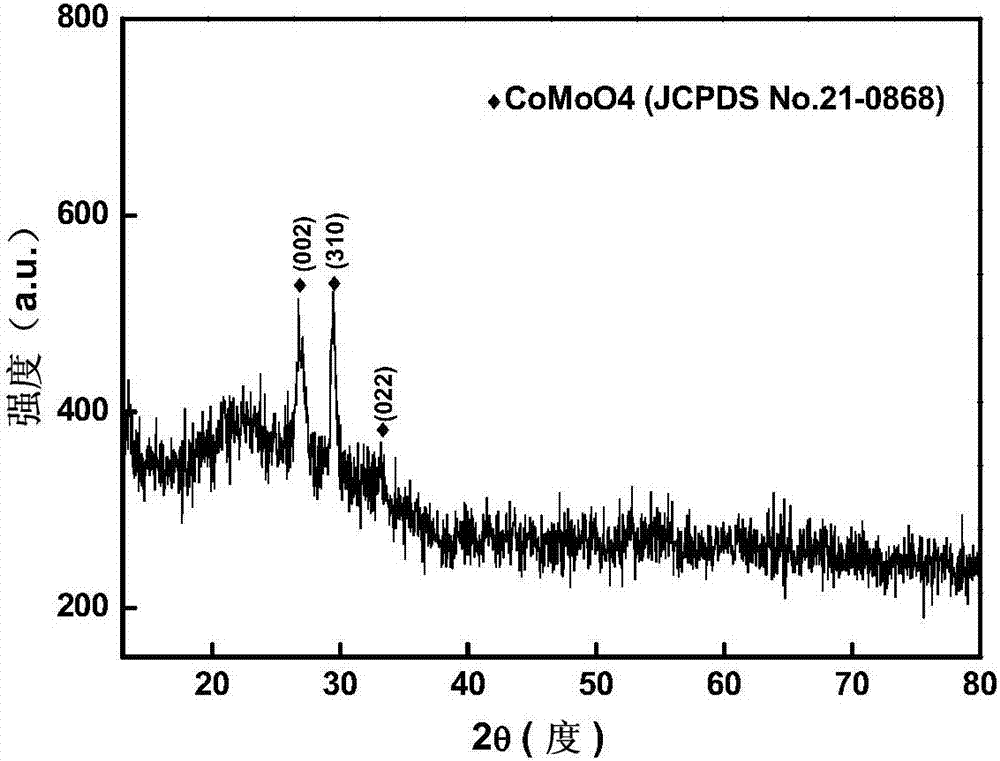

[0060] (1) Dissolve 1.5mmol cobalt nitrate and 1.5mmol sodium molybdate in 35mL deionized water, stir at 30°C for 10 minutes to obtain a uniform solution A; add pretreated nickel foam, transfer to a clean reaction kettl...

Embodiment 2

[0068] A kind of MoSe for electrocatalytic water splitting 2 / Co 0.85 The preparation method of Se composite material, comprises steps as follows:

[0069] (1) Dissolve 1.5mmol cobalt nitrate and 1.5mmol sodium molybdate in 35mL deionized water, stir at 30°C for 10 minutes to obtain a uniform solution A; add pretreated nickel foam, transfer to a clean reaction kettle, and heat up To 160°C, keep warm for 10 hours. After natural cooling, it was alternately washed three times with deionized water and absolute ethanol, and dried in vacuum at 40°C for 5 hours to obtain the coated composite material precursor CoMoO 4 nickel foam;

[0070] (2) Dissolve 0.16g of sodium borohydride in 35mL of deionized water to obtain solution B; add 0.16g of selenium powder, and stir at 35°C under an argon atmosphere for 40 minutes to prepare reaction solution C; Add the nickel foam of the composite material precursor prepared in step (1) into the reaction solution C, and put it in a clean reactio...

Embodiment 3

[0072] A kind of MoSe for electrocatalytic water splitting 2 / Co 0.85 The preparation method of Se composite material, comprises steps as follows:

[0073] (1) Dissolve 1.5mmol cobalt nitrate and 1.5mmol sodium molybdate in 35mL deionized water, stir at 30°C for 10 minutes to obtain a uniform solution A; add pretreated nickel foam, transfer to a clean reaction kettle, Raise the temperature to 160°C and keep it warm for 10 hours; after natural cooling, alternately wash three times with deionized water and absolute ethanol respectively, and dry in vacuum at 40°C for 5 hours to obtain CoMoO coated with the composite material precursor 4 nickel foam;

[0074](2) Dissolve 0.16g of sodium borohydride in 35mL of deionized water to obtain solution B; add 0.16g of selenium powder, and stir at 45°C under an argon atmosphere for 50 minutes to obtain reaction solution C; Add the nickel foam of the composite material precursor prepared in step (1) into the reaction solution C, and put i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com