Method of synthesizing 2,2,4,4-tetramethyl-1,3-cyclobutadione

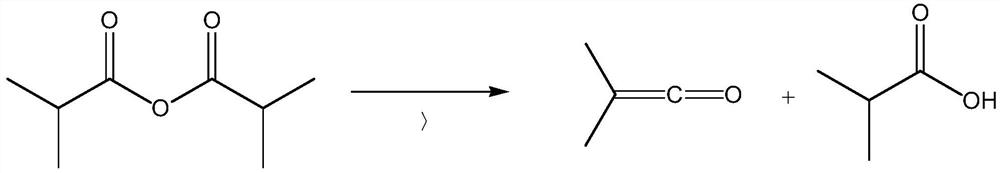

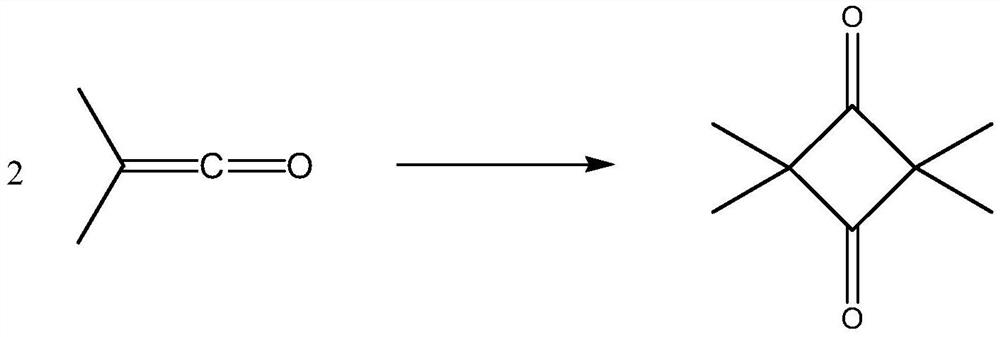

A technology of cyclobutanedione and a synthesis method, which is applied in the preparation of carbon-based compounds, chemical instruments and methods, preparation of ketene, etc., can solve the problems of low DMK concentration, affecting the activity and life of a hydrogenation catalyst, and complicated operation procedures.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Isobutyric anhydride (IBAN, 4.17ml / min) and nitrogen (200ml / min) were mixed in a mixing tank at 150°C to form a mixed gas with an IBAN concentration of 75mol%. The mixed gas is introduced into a preheating reactor at 325°C for preheating, and then introduced into a cracking reactor at 475°C to crack IBAN at a reaction pressure of 110torr. The gas residence time of the above cracking reaction is 0.14 seconds, the total reaction is 1 hour, the conversion rate of IBAN is 62.9%, and the selectivity rate of dimethyl ketene (DMK) is 97.2%. The cracked product (containing unreacted IBAN, main product DMK, and by-product isobutyric acid (IBA)) quickly passes through the condenser and cools down to between 30°C and 40°C to form a gas-liquid mixture. The liquid in the gas-liquid mixture is mainly unreacted IBAN and by-product IBA, while the gas is mainly DMK. The gas-liquid mixture after cooling is carried out gas-liquid separation by separating device, then the gas product impo...

Embodiment 2

[0034] IBAN (4.17 ml / min) and nitrogen (100 ml / min) were mixed in a mixing tank at 150° C. to form a mixed gas with an IBAN concentration of 87 mol%. The mixed gas is introduced into a preheating reactor at 325°C for preheating, and then introduced into a cracking reactor at 475°C to crack IBAN at a reaction pressure of 110torr. The gas residence time of the above cracking reaction is 0.16 seconds, the total reaction is 1 hour, the conversion rate of IBAN is 63.0%, and the selectivity of DMK is 98.3%. The cracked product (containing unreacted IBAN, main product DMK, and by-product IBA) quickly passes through the condenser and cools down to between 30°C and 40°C to form a gas-liquid mixture. The liquid in the gas-liquid mixture is mainly unreacted IBAN and by-product IBA, while the gas is mainly DMK. The gas-liquid mixture after cooling is carried out gas-liquid separation through the separation device, then the gas product is introduced into (bubble) absorption bottle (total ...

Embodiment 3

[0036] IBAN (4.17ml / min) was passed into the mixing tank at 150°C to form a gas with an IBAN concentration of 100mol%. After the gas is introduced into a preheating reactor at 325°C for preheating, it is introduced into a cracking reactor at 475°C to crack IBAN at a reaction pressure of 110torr. The gas residence time of the above cracking reaction is 0.18 seconds, the total reaction is 1 hour, the IBAN conversion rate is 59.4%, and the DMK selectivity rate is 98.4%. The cracked product (containing unreacted IBAN, main product DMK, and by-product IBA) quickly passes through the condenser and cools down to between 30°C and 40°C to form a gas-liquid mixture. The liquid in the gas-liquid mixture is mainly unreacted IBAN and by-product IBA, while the gas is mainly DMK. The gas-liquid mixture after cooling is carried out gas-liquid separation through the separation device, then the gas product is introduced into (bubble) absorption bottle (total 2 bottles) in 0 ℃ IIBB (the first b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com