Soybean protein composite polymer micro-gel-based radical antioxidant and preparation method thereof

A composite polymer and soybean protein technology, which is applied in the field of soybean protein composite polymer microgel-based antioxidants and its preparation, can solve the problems of limited application, low swelling performance of pure PVA gel, and reactive inertness, and achieve oxygen The effect of improving the ability of free radicals

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

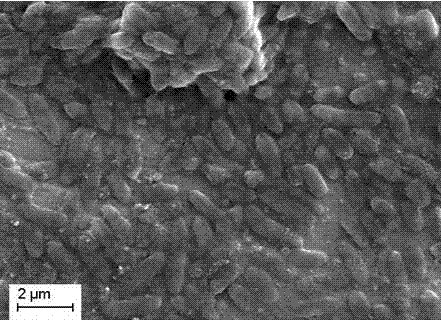

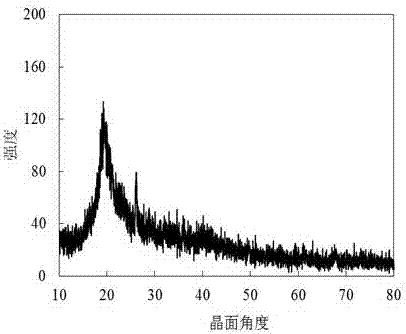

Image

Examples

Embodiment 1

[0034] (1) Preparation of soybean protein isolate dispersion: take 0.01 g of soybean protein isolate, disperse it in 10 mL of 0.5 mol / L NaOH aqueous solution, and prepare a soybean protein isolate dispersion with a concentration of 1 mg / mL;

[0035] (2) Preparation of soybean protein isolate composite polymer microgel: Heat the above soybean protein isolate dispersion to 50°C under stirring, and add 60 mL of 0.5 mg / mL polyethylene dropwise with a syringe at a constant speed under high-speed (600 rpm) stirring Alcohol solution (containing 0.03 g of polyvinyl alcohol), continued to stir for 1 h after dripping, frozen at –20 °C for 24 h, thawed at room temperature for 24 h, and dialyzed in distilled water for 24 h with a 2000 Da dialysis bag (replace 3 ~5 dialysate), to obtain soybean protein isolate composite polymer microgel;

[0036](3) Preparation of soybean protein composite polymer microgel-based antioxidant: Add the above soybean protein isolate composite polymer microgel ...

Embodiment 2

[0039] (1) Preparation of soybean protein isolate dispersion: take 0.025 g of soybean protein isolate, disperse it in 10 mL of 1mol / L NaOH aqueous solution, and prepare a soybean protein isolate dispersion with a concentration of 2.5 mg / mL;

[0040] (2) Preparation of soybean protein isolate composite polymer microgel: Heat the above soybean protein isolate dispersion to 70°C under stirring, and add 50 mL of 2 mg / mL polyethylene dropwise at a constant speed with a syringe under high-speed (700 rpm) stirring Alcohol solution (containing 0.1 g of polyvinyl alcohol), continued to stir for 5 h after dripping, frozen at –15 °C for 12 h, thawed at room temperature for 36 h, and dialyzed in distilled water for 12 h with a 10,000 Da dialysis bag (replace 3 h during the dialysis process). ~5 dialysate), to obtain soybean protein isolate composite polymer microgel;

[0041] (3) Preparation of soybean protein composite polymer microgel-based antioxidant: add the above soybean protein iso...

Embodiment 3

[0044] (1) Preparation of soybean protein isolate dispersion: take 0.02 g of soybean protein isolate, disperse it in 10 mL of 2.5mol / L KOH aqueous solution, and prepare a soybean protein isolate dispersion with a concentration of 2 mg / mL;

[0045] (2) Preparation of soybean protein isolate composite polymer microgel: Heat the above soybean protein isolate dispersion to 90°C under stirring, and add 20 mL of 6 mg / mL polyethylene dropwise at a constant speed with a syringe under high-speed (800 rpm) stirring Alcohol solution (containing 0.12 g of polyvinyl alcohol), continued to stir for 2.5 h after dripping, frozen at –10°C for 36 h, thawed at room temperature for 12 h, and dialyzed in distilled water for 36 h with a 18,000 Da dialysis bag (need to be replaced during the dialysis process for 3~ 10 times of dialysate) to obtain soybean protein isolate composite polymer microgel;

[0046] (3) Preparation of soybean protein composite polymer microgel-based antioxidant: Add the abov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com