Energy-saving and environment-friendly air energy drying machine for shrimp shells

An energy-saving, environmental-friendly, air-energy technology, applied in dryers, drying, drying of solid materials, etc., can solve the problems of low drying efficiency and difficult to control drying humidity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

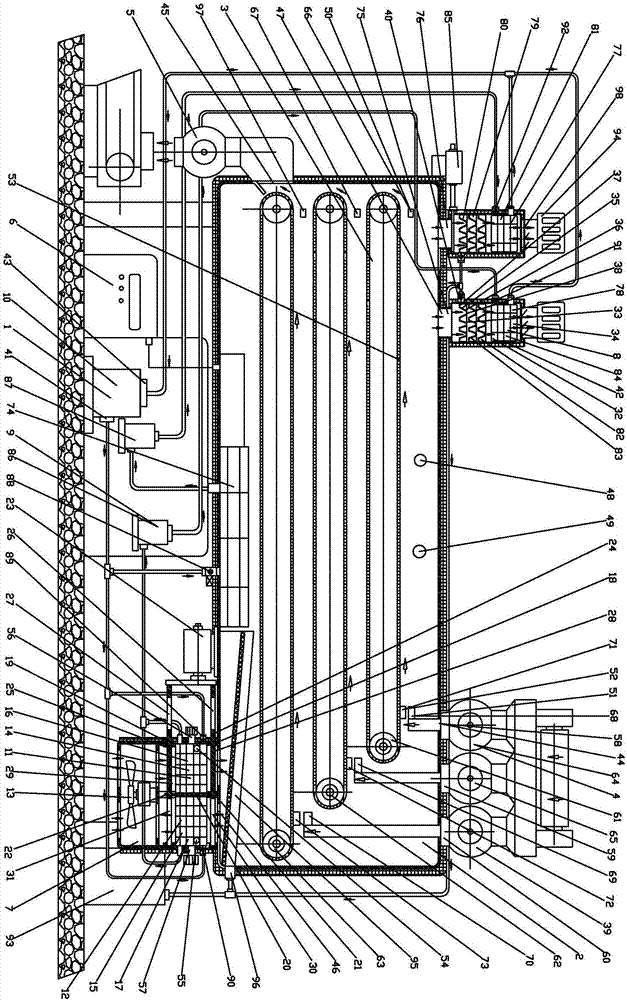

[0008] Below in conjunction with accompanying drawing, the present invention is further described:

[0009] Such as figure 1 The schematic diagram of the structure of the energy-saving and environment-friendly air energy shrimp shell dryer is shown. The energy-saving and environment-friendly air energy shrimp shell dryer includes a heat pump device 1, a drying box 2, a belt conveyor 3, a rotary feed valve 4, and a rotary discharge valve. 5 and a controller 6; the heat pump device 1 includes a hot air drying device 7, a deodorizing device 8, an expansion valve 9 and a compressor 10; in order to prevent moist air from entering the drying box 2, the hot air drying device 7 is used to dry the air and Heating; the hot air drying device 7 includes a first air moisture absorption box 11, a second air moisture absorption box 12, a fan 13, a first condenser 14, a second condenser 15, a first air moisture absorption grid 16 and a second air Moisture-absorbing grid 17, the first air moi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com