Modified epoxy resin and glass fiber reinforcement plate prepared based on same

An epoxy resin, glass fiber technology, applied in glass/slag layered products, layered products, chemical instruments and methods, etc., can solve the problem that the toughness and high temperature resistance cannot be improved at the same time, and the low temperature resistance limits the use of products, The problem of single-targeted modifiers can achieve the effects of good adhesion, excellent comprehensive performance, and improved heat resistance and toughness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

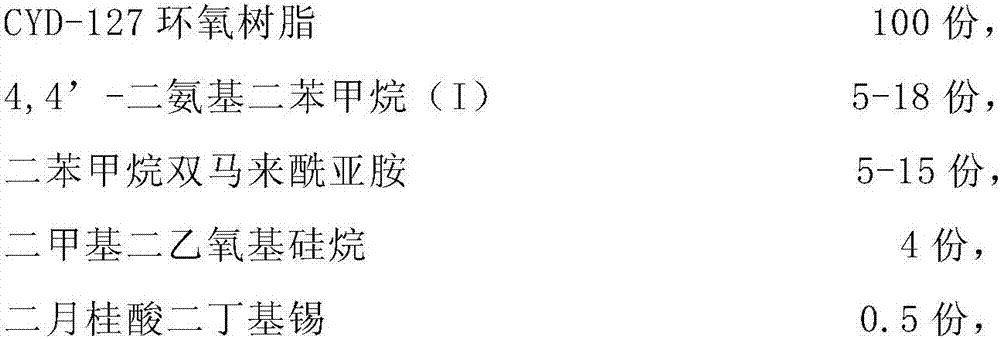

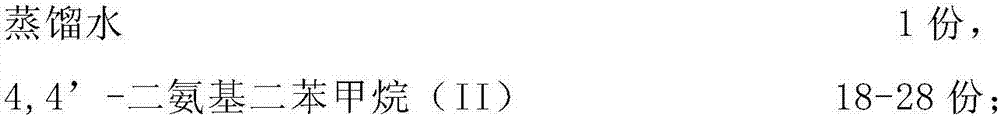

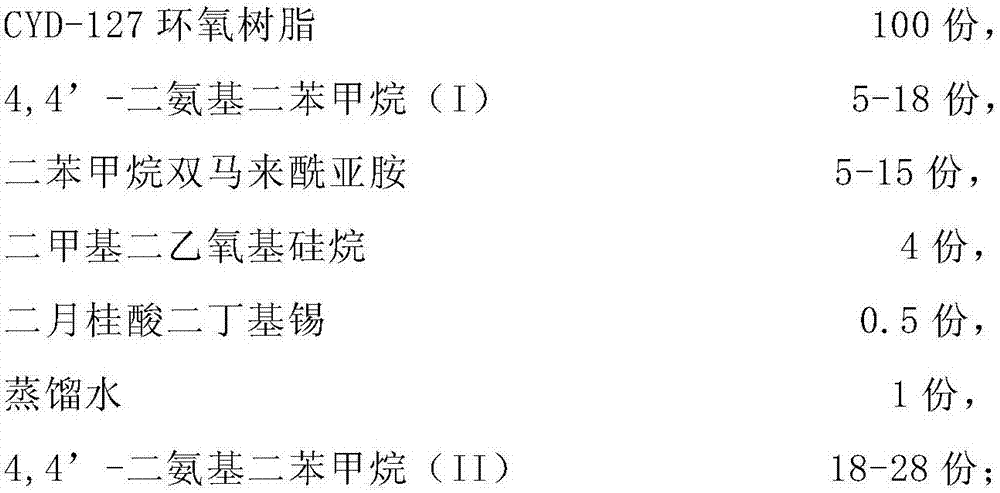

[0029] Prepare modified epoxy resin, the steps are as follows:

[0030] 1) Mix 4g of dimethyldiethoxysilane and 100g of CYD-127 epoxy resin (viscosity at room temperature: 350mPa·s, gel time: 20min), heat up to 80°C, add 0.5g of dibutyltin dilaurate and 1g of distilled water, then continue to heat up to 95°C, keep warm for 5.5h to make the chemical mixing reaction between dimethyldiethoxysilane and epoxy resin fully occur, at this time the reaction liquid changes from clear to milky white, indicating that the reaction is complete, and it is removed by vacuum distillation By-products obtain silicone-modified epoxy resins;

[0031] 2) Melt 5g of diphenylmethane bismaleimide and 5.53g of 4,4'-diaminodiphenylmethane in an oil bath at 135-140°C in advance to cause Michael addition reaction to occur, and stop heating after 5 minutes of reaction Cool down to 95-100°C, add the obtained silicone-modified epoxy resin, mix thoroughly in an oil bath at 135-140°C, stir evenly, stop heatin...

Embodiment 2

[0035] Preparation of glass fiber reinforced laminates, the steps are as follows:

[0036] 1) Mix 4g of dimethyldiethoxysilane and 100g of CYD-127 epoxy resin (viscosity at room temperature: 380mPa·s, gel time: 24min), heat up to 80°C, add 0.5g of dibutyltin dilaurate and 1g of distilled water, then continue to heat up to 90°C, keep warm for 5.5h to make the chemical mixing reaction of dimethyldiethoxysilane and epoxy resin fully occur. By-products obtain silicone-modified epoxy resins;

[0037] 2) Melt 5g of diphenylmethane bismaleimide and 5.53g of 4,4'-diaminodiphenylmethane in an oil bath at 135-140°C in advance to cause Michael addition reaction, stop heating after 5 minutes of reaction Cool down to 95-100°C, add the silicone-modified epoxy resin obtained in step 1), mix thoroughly in an oil bath at 135-140°C, stir evenly, stop heating and wait until it cools to room temperature, then add 28g of 4,4'- Diaminodiphenylmethane, vacuum defoaming and stirring evenly to obtai...

Embodiment 3

[0041] Preparation of glass fiber reinforced laminates, the steps are as follows:

[0042] 1) Mix 4g of dimethyldiethoxysilane and 100g of CYD-127 epoxy resin (viscosity at room temperature: 400mPa·s, gel time: 30min), heat up to 80°C, add 0.5g of dibutyltin dilaurate and 1g of distilled water, then continue to heat up to 95°C, and keep warm for 5 hours to fully chemically mix the dimethyldiethoxysilane and epoxy resin. At this time, the reaction solution changes from clear to milky white, indicating that the reaction is complete. The product obtains the epoxy resin modified by organosilicon;

[0043] 2) Melt 10g of diphenylmethane bismaleimide and 11.3g of 4,4'-diaminodiphenylmethane in an oil bath at 135-140°C in advance to cause Michael addition reaction to occur, and stop heating after 5 minutes of reaction Cool down to 95-100°C, add the obtained silicone-modified epoxy resin, mix thoroughly in an oil bath at 135-140°C, stir evenly, stop heating and add 23g of 4,4'-diamin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thermal decomposition temperature | aaaaa | aaaaa |

| Impact strength | aaaaa | aaaaa |

| Bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com